Pneumatic Sample Press TF515

Pneumatic Sample Press or Pneumatic Sample Cutter, is a new type of desktop sample press, to cut samples for testing or other use. This sample cutter is a wide scope in adhesive and labels testing, film and foils testing, and so forth. Its lightweight, reliable performance and conformance to testing standards make this pneumatic sample press highly regarded. Pneumatic Sample Press complies with ISO3801, ASTM D3776/2646, BS 3424/2471, etc.

Description

Application

Pneumatic Sample Press or Pneumatic Sample Cutter, is a new type of desktop sample press, to cut samples for testing or other use. This sample cutter is a wide scope in adhesive and labels testing, film and foils testing, and so forth. Its lightweight, reliable performance, and conformance to testing standards make this pneumatic sample press highly regarded.

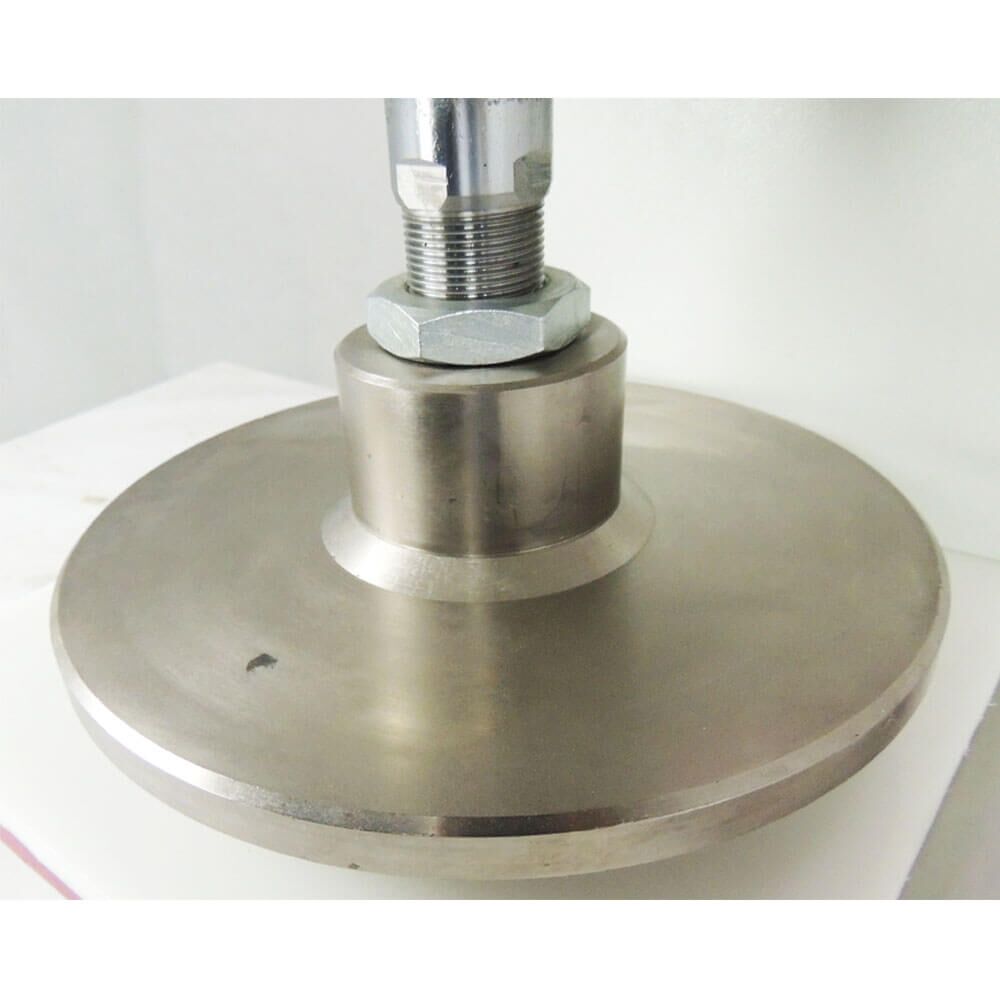

The pneumatic press machine equips with a 125 mm cylinder, a cutting depth of 10mm, and 125 x 125mmn tables. Under the pressure of 100 psi can produce 800kg/f pressure, equipped with a double bond security operation.

In addition, the press pneumatic can provide a special shape die according to the demands of our customers. Laboratory standards compression air is required. More importantly, cutting dies in most sizes and shapes can also be offered on request with drawings.

Weight

| 65kg |

Air Source

| 0.5-0.6Mpa |

Dimensions

| Length: | 400 mm | Width: | 440 mm | Height: | 650 mm |

Standards

| ISO 3801 | ASTM D3776 | ASTM 2646 | BS EN 12127 |

Features

Highly efficient and save time

Equipped with the one-button operation, high-pressure air source and all kinds of high steel die mold, solves the problem of time-consuming cutting samples.

Safe and accurate test

Quickly and effectively ensure the smooth progress of the perfect tests and sample reliability, provided with automatic sample ejection and safety 2-button operation.

Meet various needs

The press pneumatic can provide special shape dies according to the demands of our customers.

Longer service life

The whole machine is made of high-quality metal, a 5-layer plating process,anti-corrosion, and rust prevention.

How does a pneumatic press work?

Pneumatic sample cutter uses pneumatic power to drive the press cylinder and then presses the standard cutter through the platen to cut the standard specimen.

Designs for this machine meet the requirements of ISO 3801, ASTM D3776, ASTM 2646, BS EN 12127.

Why choose TESTEX Pneumatic Sample Press TF515

Strictly meet standards:

All data for the pneumatic press machine meet the standard parameters, for example, ISO 3801, and ASTM D3776.

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High reproducibility:

Whether is the same set of samples, or different machines of the same model, after multiple tests, the results are consistent.

Longer service life:

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy:

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Pneumatic Sample Press TF515. So feel free to contact our service team with any questions you may have.

Welcome to TESTEX – a professional textile testing instrument supplier – Pneumatic Sample Press TF515 is on sale, contact us to get a detailed price quote.

6 reviews for Pneumatic Sample Press TF515

You must be logged in to post a review.

What is a Pneumatic Sample Cutter?

Sample pneumatic cutting machine, equipped with a cutting model, cutting the test samples according to different standards, simple operation and safe operation. When cutting the sample, the force is uniform and the edge is neat, providing a high-quality sample for the test standard.

Test principle

A pneumatic sample cutter uses pneumatic power to drive the press cylinder and then presses the standard cutter through the platen to cut the standard specimen.

Designs for this machine meet the requirements of ISO 3801, ASTM D3776, ASTM 2646, and BS EN 12127.

Operating Steps

1 Connect the machine with the air supply.

2 Connect the machine with the power supply.

3 Place the cutting pad on the working platform, adjust the height of platen by adjusting the by adjusting the screws.

4 Place the sample to be cut on the cutting pad.

5 Place the suitable cutting die on the sample.

6 Press and hold the start button for certain times to cut samples.

7 Release two start buttons to lift the platen, then take out the cutting dies and the cut sample.

Note

Two start buttons should be pressed at the same time when cutting the sample; it is used to protect our hands from the damaged by the machine.

The air supply can be adjusted when cut sample, to make sure the safe of operator and avoid the damage of cutting die, the air supply should be adjusted slowly.

Be careful the sharp edge when touch the cutting dies.

[contact-form-7 id="16355" title="Inquiry"]

Walker Brooke –

Great value. Works great.

Cornelia Geoffrey –

Very nice for the price and the quality is supreme!

Randolph Hope –

Works well and its easy to use.

Allen Tate –

It works quite well.

Jesse Sam –

Thank you very much for an excellent product.

testextextile –

The pneumatic Sample Press is in great condition