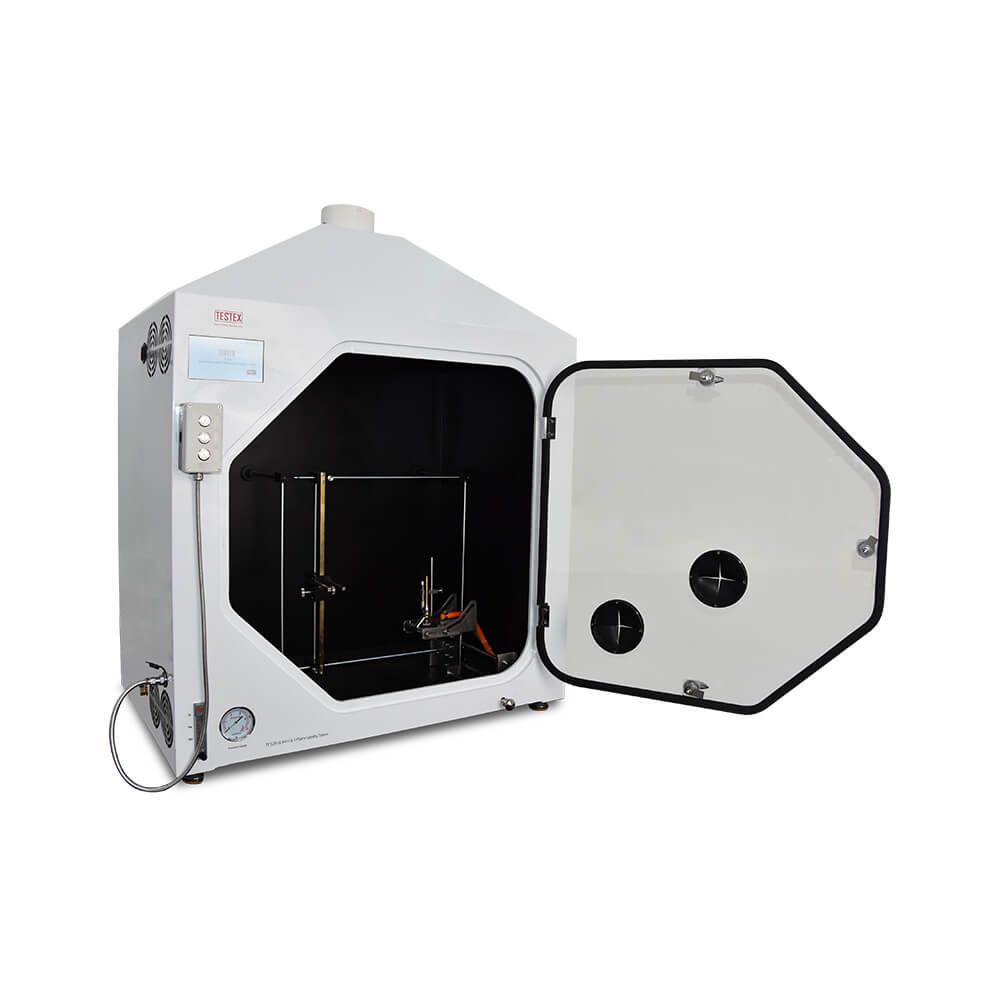

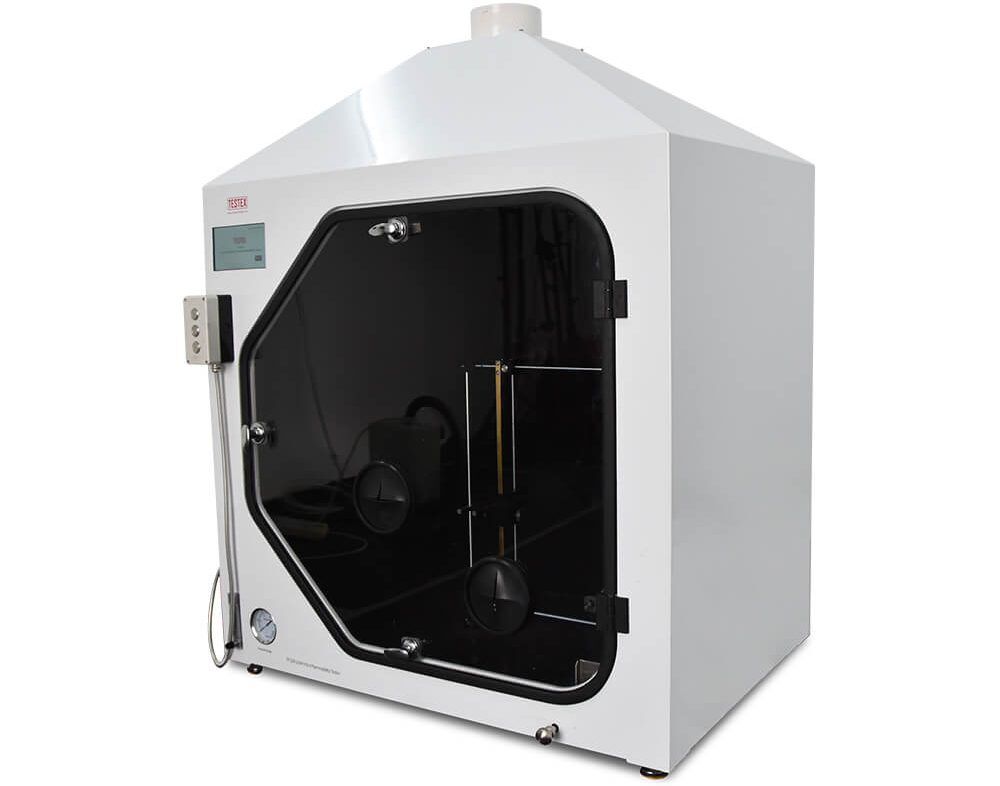

UL94 Horizontal & Vertical Flammability Tester TF328

The UL94 Horizontal & Vertical Flammability Tester, or UL94 Horizontal Vertical Burning Tester, is used to test fabric flammability. It also tests the burning of plastic, rubber, or film under a specified fire source to determine their fire resistance. This Flammability Testing Equipment is also used for lighting, appliances, motors, tools, and instruments. We typically use this flammability chamber for research, production, and quality inspection.

The UL94 Horizontal & Vertical Flammability Tester TF328 is a widely recognized tool in the textile industry. It features a gas flow meter that allows for safe and easy adjustments to the flame size. This Flammability Tester meets various standards, including UL HB, UL94, UL 94 V0, and ISO 9772/9773. For guidance on operating the Flammability Test, we invite you to watch our instructional video on the UL 94 flammability test. Additionally, you can explore flammability test standards and burn-in test standards. Please feel free to reach out to us for information regarding the Flammability Tester pricing.

Description

Specification of UL94 Flammability Tester

| Model | TF328 |

| Power | 220/110 V, 50/60 Hz |

| Net Weight | 90 Kg |

| Dimensions | 1060 mm * 740 mm * 1360 mm |

Standards of UL94 Flammability Tester

| UL 94 HB, UL 94 V0, UL 94 V1, UL 94 V2, UL 94 5VA |

| UL 94 5VB, UL 94 VTM-0, UL 94 VTM-1, UL 94 VTM-2, UL 94 HF-1 |

| UL 94 HF-2, UL 94 HBF, ISO 9772, ISO 9773, ASTM D635,ASTM D3801,ASTM D4804,ASTM D4986 |

| GB/T 2408, GB/T 8332, (optional standards: ASTM D5207, IEC60695-11-3 Method A, IEC60695-11-4) |

Features of UL94 Horizontal & Vertical Flammability Tester TF328

The Flammability Test Chamber has X, Y, and Z axes. They can be moved freely. This makes it easy for customers to position the specimen and track the flame during combustion.

It has an ASTM D 5025-compliant burner.

You can adjust its angle simply to 0°, 20°, or 45°. This Flammability Testing Equipment has a precise gas control system. This system includes a gas flow meter, pressure regulator, and pressure gauge.

The Flammability Tester has microcomputer control.

It has a high level of automation. It records test time and shows test results. It times, ignites, and alarms automatically. It also returns the Bunsen burner after the flame ends. The Flammability Test Chamber makes it easy to perform horizontal and vertical flammability and burning tests.

Large space, easy operation.

The flammability chamber has a large internal volume of 0.9 square meters. Also, the flame test chamber has internal lighting. It also has an exhaust fan to vent combustion products.

The door and window are well-designed. They are made of tempered safety glass, which lets the specimen be seen during the UL 94 test. This Flammability Tester is fully adjustable for horizontal and vertical specimen holders. So It is also called horizontal flammability and vertical flammability tester.

Two access ports provide easy access to the Flame Test Chamber for moving the burner and specimen. It has one burner wing tip. And, it has three digital timers for test durations. They make operations accurate but simple.

Application of UL94 Horizontal & Vertical Flammability Testing Machine TF328

Electronics: Ideal for testing flame resistance in insulated enclosures, switch panels, circuit boards, and insulating materials of electronic devices.

Plastics: Used to assess flammability in plastic and non-metallic materials under 50W flame in both horizontal and vertical orientations.

Other Materials: Applicable to lighting fixtures, electrical devices, motors, tools, and components like engineering plastics and insulating materials, ensuring compliance with fire safety standards.

In addition, TESTEX offers flammability testers for a wide range of materials, which can perform vertical flammability tests, horizontal flammability tests, 45-degree flammability tests, glow wire flammability tests, etc. Our flammability testing equipment is safe and accurate enough to be your best assistant in the flammability test labs. Those flammability test apparatus comply with ASTM D1230, ISO 9772, ISO 15025, FTMS 191-5908, BS EN71-2:2006, ASTM D6413, UL HB, and other standards.

Know more about the UL94 Flame Test

UL94 flammability ratings and test plan

UL94 standard can be divided into 12 fire ratings: HB, V-0, V-1, V-2, 5VA, 5VB, VTM-0, VTM-1, VTM-2, HBF, HF1, HF2. Of these, VTM-0, VTM-1, and VTM-2 are suitable for plastic films and HBF, HF1, and HF2 for foamed materials.

| HB rating | Horizontal Burning Test |

| V0-V2 rating | Vertical Burning Test |

| 5V rating | Vertical Burning Test |

| RP Class | Radiant Panel Flame Spread Test |

| VTM0-VTM2 | Thin Material Vertical Burning Test |

| HF1-HF2 | Horizontal Burning Foamed Material Test |

Five UL 94 horizontal and vertical burner tests

| 50W flame horizontal combustion test UL94 HB40, HB75 classification | |

| 50W flame vertical combustion test V-0, V-1, V-2 classification | |

| 500W flame burning test 5VA, 5VB classification | |

| Horizontal burning HF-1, HF-2 and HBF classification for foam materials | |

| VTM-0, VTM-1 and VTM-2 classification for vertical burning of soft specimens of film materials |

Related Standards of UL94 Horizontal&Vertical Flammability Tester TF328

| Horizontal flammability test | UL HB, IEC 60695-11-10, IEC60707, ISO 1210, GB/T 2408 |

| 50W vertical flammability test | UL94 V0, V1, V2, IEC60695-11-10, ISO 1210, GB/T 2408 |

| 500W vertical flammability test | 5VA, 5VB, IEC 60695-11-20, ISO 9770, GB/T 5169.17 |

| Thin flexible material vertical flammability test | VTM-0, VTM-1, VTM-2, ISO 9773 |

| Cellular plastic material horizontal flammability test | HF-1, HF-2, HBF, ISO 9772, GB/T 8332 |

TESTEX – a professional textile testing instrument supplier – UL94 Horizontal & Vertical Flammability Tester TF328 is on sale, contact us to get a detailed price quote.

11 reviews for UL94 Horizontal & Vertical Flammability Tester TF328

You must be logged in to post a review.

FLAMMABILITY UL 94 V (50 W, 20 mm Vertical)

Objectives

This vertical flammability test is to determine the UL flammability rating v0 and flammability rating v1 and v2. The test evaluation includes the burning time, afterglow time, and the dripping of the combustion test sample.

Flammability Testing Equipment

UL94 Flammability test chamber

Pretreatment

- The relative humidity is 2 days/ 23℃/ 50%, and the hot air oven is 7 days/ 70℃.

- The flame height should be controlled to 20mm.

- The flame application time is 2×

- When the first burning time is over, the second flame application time begins.

UL flammability rating chart

FLAMMABILITY UL 94 HB (Horziontal Burning)

Objectives

The UL 94 horizontal burn test is a fire rating testing of material. Calculating the flammability rating for the burning rate of the specimen and taking the thickness into account.

Equipment

UL94 Flame test chamber

Pretreatment

- Control the experimental environment to 48 hours / 23°C / relative humidity.

- Adjust the flame height to 20mm.

- The ignition time is the 30s.

- If the flame front reaches the first mark within 30 s, the ignition should be stopped.

What Criteria to Consider when Using the Vertical Flammability Tester ( Flame Chamber) to Test the Flammability?

1. When making a sample, the sewn material must be the same as the material composition and size used for sewing garments and the same seam method. The trim used lengthwise should be stitched to the full width (shorter side) of the specimen, and the trim not used lengthwise should be stitched to the full length (longer side) of the test specimen. What Criteria to Consider when Using the Vertical Flammability Tester to Test the Flammability?

2. After drying the sample in the dryer, cooling time should not exceed 60 minutes.

3. When adjusting the flame length of the burner, the lighting of the extraction cabinet and the extraction fan should be turned off to dim the ambient light, and air should be turned off. After the flame length has been initially adjusted, it should be allowed to burn for a period of time before checking to ensure Flame length stability. When adjusting the position of the burner, the blue outer flame of flame should be brought into contact with the lower edge of the test specimen and the lower edge of the test specimen should be equally divided in order to ignite the test sample most effectively. Remove the sample from the dryer to start the ignition combustion. This must be completed within 45 seconds, if it is longer than 45 seconds, the sample must be re-dried and cooled before testing.

4. When carrying out the burning test, some materials will produce smoke with high toxicity. When the test is carried out, a gas mask, safety glasses and the like should be worn. When the burning of each sample is completed, an exhaust fan should be used to prevent excessive smoke that may harm and pollute the environment.

If you need fire retardant testing standards, please don’t hesitate to contact us.

A: Yes. Please contact us for more details.

Q: What is the meaning of 50W in the "50W (20 mm) Vertical Burning Test; V-0, V-1, or V-2?"

A: 50W, 500W refers to the burning power of the torch, which is generally designated by UL as the burning torch.

Q: Is the UL94 Horizontal & Vertical Flammability Testing Machine TF328 a combination of the Vertical Flammability Tester, 45 Degree Flammability Tester, and Horizontal Flammability Tester? Can it perform all three tests?

A: The UL94 Horizontal & Vertical Flammability Testing Machine TF328 is primarily used for horizontal and vertical burning tests, but it does not include the functionality for 45-degree burning tests. Therefore, the TF328 is a combination of horizontal and vertical burning testers, but it is not suitable for 45-degree burning tests.

If a 45-degree burning test is required, a specialized 45-degree flammability tester is typically needed.

Q: Why does the igniter fail to ignite the sample or the flame extinguishes quickly?

A: This issue can occur due to the following reasons:

Gas Pressure and Flow Issues: Ensure that the gas supply is consistent and the pressure is at an appropriate level. Either too low or too high pressure can affect ignition.

Igniter Problems: Check if the igniter is clogged or damaged. Clean or replace the igniter as necessary.

Distance Calibration: Ensure the distance between the igniter and the sample is within the standard range. Too close or too far can affect stable ignition.

Q: What should I do if the sample is not positioned horizontally during the UL94 flammability test?

A: Ensure that the sample is securely fixed at a 45-degree angle during the flammability test.

Q: How can I ensure accurate flame contact time during the UL94 test?

A: To achieve accurate flame contact time, carefully control both the flame duration and the distance between the flammability tester and the sample.

Q: What could cause the after-flame time to be too long?

A: If the after-flame time is too long, verify whether the material meets the flame retardant requirements for V-0 or V-1 classifications. Longer after-flame times might indicate a lower flame retardancy.

Q: How can I deal with inconsistent results in repeated UL94 tests?

A: Perform multiple tests and calculate the average result to improve the reliability of the final outcome.

Q: What are the standards for flammability test levels for plastics?

A: (1) GB/T2408-2008 Determination of Flammability Properties of Plastics by Horizontal and Vertical Methods

(2) GB/T2406.2-2009 Plastics: Determination of burning behaviour by oxygen index method.

(3) American Standard UL94 Flame Retardant Grade

Others are GB/T8924-2005 "Test Method for Combustion Performance of Fibre Reinforced Plastics Oxygen Index Method", ASTM D2863, GB/T 5169.16, GB/T 5169.17, GB 4943.1 and so on.

Among them, 94-V is UL94 vertical combustion test classification standard, mainly divided into V0, V1, V2 three levels (GB2408-2008 vertical test is also V0, V1, V2 three levels), UL94 and 5VA and 5VB two levels, is also the highest level of flame retardant plastics. Different levels require different technical indicators.

Daniel Li –

For ul94 standards testing, you can not expect more from this tester model, both vertical and horizontal are available.

Annabelle Dunlop –

Happy with the purchase. Arrived quickly and the results has been accurate.

Warner Ralph –

I have never left a product review before, but with the results I’ve received from this flammability tester I absolutely had to.It’s worthy.

Una Babbitt –

Awesome and affordable. Works great.

Paul –

It is a enjoyable process to have a successful deal with you. Very nice.

Natalie Herbert –

This flammability testing equipment is pretty good

Sophia Cronin –

This big box is awesome, with reasonable price.

Modesty Chapman –

The flammability testing machine looks beautiful. I believe its function is also beautiful (havevn’t used yet).

Jill –

Спасибо. все отлично.

testextextile –

Thank you for your support. Look forward to your next visit.

Joy Grote –

Wonderful product, love it. Very well polish

testextextile –

Waiting for your next order

Anonymous –

Good device, for a reasonable price. Manufacturer and seller thanks!!!