Now, mask factories in European and American countries are facing some pressure: on the one…

TOP 3 Misleading Features of Mask Making Machine In the Market

Table of Contents

No.1 About UV sterilization function on mask machine, does it work?

A most misleading function for medical mask manufacturers!

Quick takeaway: If you a medical mask manufacturer, you can not depend on the UV sterilization equipped on the mask machine for identifying the masks you produced for medical purpose, if so, you are misleading your clients since this is not the right way to distinct the masks.

Below information is from the FDA website:

https://www.fda.gov/medical-devices/coronavirus-covid-19-and-medical-devices/uv-lights-and-lamps-ultraviolet-c-radiation-disinfection-and-coronavirus

In addition to understanding whether UVC radiation is effective at inactivating a particular virus, there are also limitations to how effective UVC radiation can be at inactivating viruses, generally.

- Direct exposure: UVC radiation can only inactivate a virus if the virus is directly exposed to the radiation. Therefore, the inactivation of viruses on surfaces may not be effective due to blocking of the UV radiation by soil, such as dust, or other contaminants such as bodily fluids.

- Dose and duration: Many of the UVC lamps sold for home use are of low dose, so it may take longer exposure to a given surface area to potentially provide effective inactivation of a bacteria or virus.

There is no precise data showing how much time does it take for the UV light to finish the sterilization in such scenery as mask UV light sterilization process, but from the data online, it at least takes minutes for the UV light to take affection on the bacterial’s structure, but in the mask production process, that’s impossible! at the speed of 100 pcs/min, how long you can expect the mask to stay to the UV light exposure? Not even in seconds!

If you are serious about producing medical level masks that have a critical requirement on sterilization, go for the right way:

- Invest a professional mask disinfection equipment, which involves the Ethylene oxide sterilization method, Here is a gif demonstrating the process: A batch of masks are sent into the disinfection room, and then ethylene oxide gas is passed (the yellow in the picture below is for highlighting, but it is actually colorless). After reaching a certain concentration, the disinfection process is completed. After that, air and nitrogen must be ventilated in the disinfection room to dilute and remove the ethylene oxide, so many times, until the residual amount of ethylene oxide on the surface of the mask reaches the standard.

Ethylene oxide sterilization process

- In addition, most of the disinfection links of high-end medical protective masks now use radiation disinfection, mainly using ionizing radiation to kill pathogenic microorganisms, and disinfecting disposable medical supplies. It is better than heating and ethylene oxide chemical disinfection. It is a very mature sterilization method in radiation processing.

No.2 About CCD visual detection system, why buy something you don’t need?

Think about this: when do you need a CCD detection system?

Or let’s think reversely, what the benefits disclaimed to help your mask making business by the mask machine seller?

Check the size of mask body, earloop, nose bar; check the welding position of earloop and nose bar; check nose bar embedded and ear loop breakage, thus decrease the fault rate of the masks.

From their copy, we know that the CCD system just can tell you what’s doing wrong on the masks and reject that fault masks out of the process.

But how could that happen, if the machine has been built and commissioned well?

That said, output qualified masks should be the bottom line of a high-quality mask machine, mask fault rate should be avoided during the mask machine design, building, and testing phases, should not be left to the customer production stage.

So adding an extra CCD detection system to the whole mask production line does not bring you critical benefits but looking cool or high-tech!

No.3 About fabric tension controlling system and fabric edge adjusting device

Should you go for these features?

This system you should consider if you buy mask machines at the beginning of the pandemic, but for now, they are not must-to-have features, why?

It’s true that at the very beginning of the pandemic, most (95%) of the mask machine manufacturers were new participants in this industry, not having enough experience in making easy-to-use mask machines for mask manufacturers who were also new to mask making business. A fabric tension controlling system and fabric edge adjusting device would definitely help the new mask manufacturers to start the production more quickly at that time.

But for now, in December, mask manufacturers like TESTEX, which has exported hundreds of sets of mask machine line to 27 countries, our mask machine do not need such systems, and never got a complainant from our clients, why?

Check this video, the speed at 110 pcs/min, continuous production more than one hour. no such system sighted in this automatic mask machine.

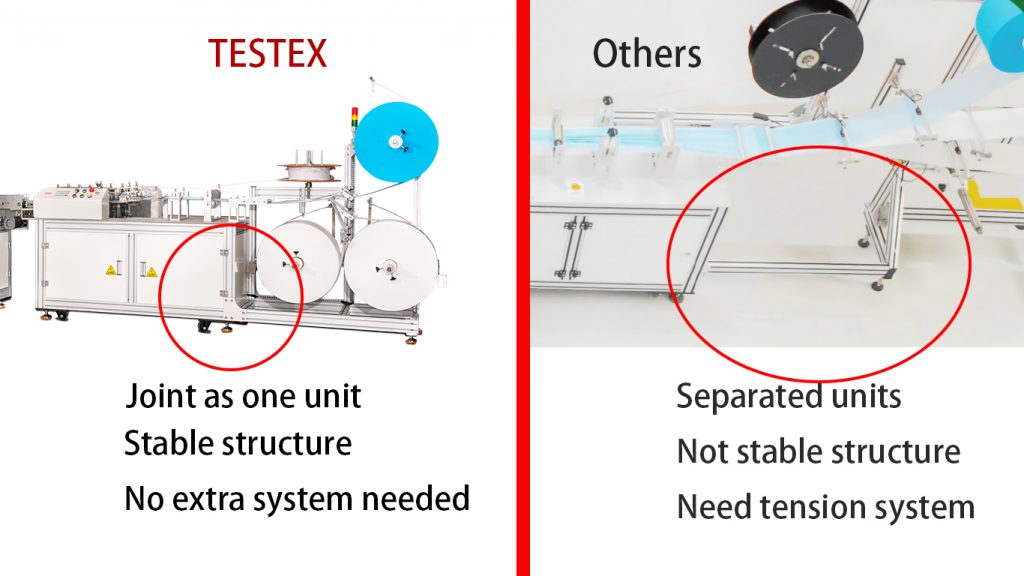

The answer is a simple truth: for mask machines like TESTEX, we design and build the fabric raw material feeding system with tension control into consideration, we use a simple but solid structure instead of complicated systems to ensure the fabric stay in the ideal tension condition and the fabric edge is not supposed to go uneven.

Below we showed you why some mask machines do need extra tension controlling system and fabric edge correction system because they shared the same unstable structure: the material feeding track and the main mask body forming machine are separated.

Extra systems always come along with extra risk, the worst thing is to adjust the adjusting system to make the machine run as you expected.

Conclusion:

You buy mask machine for mass mask production, should not be led for something that look pretty high-tech but not practical in real production, focus on what really matters to the mask production efficiency, and quality of the final masks should be your top priority on making the decision.

This Post Has 0 Comments