Sweating Guarded Hotplate TF129

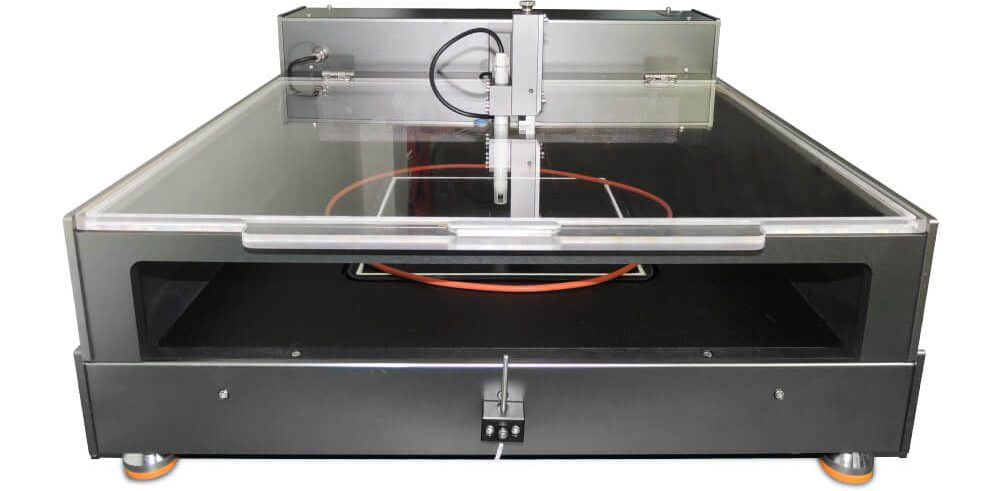

The Sweating Guarded Hotplate TF129 is a high-precision instrument designed to measure the thermal resistance and water-vapor resistance of textiles, providing essential insights into fabric comfort. The TF129 Sweating Guarded Hot Plate is a complete test system that includes a Human Skin Simulation test plate, automatic water supply system, wind speed stabilization system, test host, and climate chamber.

A Windows based software is offered. The main machine inside the chamber is connected with the software by Wi-Fi, so operators may control and monitor the testing in the office. For optimal performance, this guarded plate apparatus is offered with an advanced Temperature & Humidity Chamber to maintain consistent conditions throughout the test.

As a key Thermal Fabric Resistance Test Equipment, this guarded hot plate apparatus evaluates textiles’ ability to retain warmth and manage moisture. A higher thermal resistance indicates greater warmth, enhancing insulation, while a lower water-vapor resistance allows better breathability, contributing to wearer comfort.

Tested and trusted in over 42 countries, the Sweating Guarded Hotplate TF129 complies with multiple international standards, including ISO 11092, ASTM F1868, and GB/T 11048. As a leading hot plate apparatus provider, TESTEX also offers a range of other textile testing instruments to meet diverse needs. Get the latest Guarded Hot Plate Apparatus Price and special offers now.

Description

Parameter

| Thermal resistance range: 0.001-2 .0 m²·K/W, Resolution: 0.0001 m²·K/W |

| Evaporative Resistance range: 1-1000 m²·Pa/W, Resolution: 0.001m²·Pa/W |

| Repeatability: ≤ ±2% |

| Test plate temperature range: 30℃ ~ 40℃, adjustable, accuracy: ±0.2℃ |

| Air velocity: 0 ~ 1 m/s, adjustable, accuracy: ±1% |

| Sample thickness: 0~50 mm |

| Test plate area: 254 mm x 254 mm |

Specification

| Model | TF129 |

| Standards | ISO 11092, ASTM F1868, GB/T 11048 |

| Power | 110/220 V, 50 Hz |

| Weight | 62 Kg |

| Dimensions | 770 mm x 670 mm x 430 mm |

TESTEX – a professional textile testing instrument supplier – Sweating Guarded Hotplate TF129 is on sale, contact us to get a detailed price quote.

Features of Sweating Guarded Hotplate TF129

More advanced testing methods

The Sweating Guarded Hot Plate Apparatus utilizes a hot plate along with specialized materials, replacing the traditional porous plate. This machine effectively simulates skin sweating. We produce high-quality Guarded Hot Plate Apparatus.

More reliable test results

The Sweating Guarded Hotplate features an environmental chamber that regulates and monitors air temperature, air velocity, and humidity. This capability enhances the accuracy of Thermal Resistance and Vapor Transmission Test testing on samples.

A variety of automated systems make the test more intelligent and scientific.

This Guarded Hot Plate Apparatus features an automatic water supply and drainage system, a powerful water filling system, and a precise platform movement system.

It also inputs the test sample’s thickness and adjusts the platform to the required position. The wind speed stabilization system ensures uniform and stable wind speed, making the Sweating Guarded Hotplate Test more stable.

The software in this hot plate apparatus is user-friendly and convenient for testing, accurately calculating each index of the specimen, including thermal resistance, water vapor resistance (evaporation resistance), permeability, insulation value, and heat loss. The results and curves are displayed on the computer.

Users operate the Sweating Guarded Hotplate with an advanced temperature and humidity control chamber.

Note: This Sweating Guarded Hotplate requires a customized PC.

Application of Sweating Guarded Hotplate TF129

The Sweating Guarded Hotplate is a key tool for fabric comfort testing, measuring thermal resistance and water-vapor resistance. This Thermal Fabric Resistance Test Equipment simulates human skin to assess how well fabrics retain heat and manage moisture, critical for outdoor wear, activewear, and winter clothing. It helps manufacturers and researchers compare fabrics to select materials that balance warmth, breathability, and moisture management. Used for testing protective clothing, workwear, and outdoor gear, it ensures optimal comfort in extreme conditions. Designers also use the Sweating Guarded Hotplate to optimize fabric insulation and moisture-wicking properties.

Test Principle of Sweating Guarded Hotplate TF129

The key idea behind thermal resistance is to cover the specimen with the test plate. You also cover it with its surrounding thermal protection ring. The bottom of the protection plate stays at a constant temperature. This setup ensures that the heat of the test plate can only go through the specimen. Air can flow over the top surface of the specimen under the test conditions. We used this setup to find heat flow through the specimen. This helped us calculate its thermal resistance.

The main test principle involves covering the test plate with a breathable film. But, the film must also be impermeable. After the water enters the test plate, it evaporates and passes through the film as water vapor. So, no liquid water touches the specimen. After the specimen is placed on the film, we’ve measured the heat flow. It’s needed to keep the test plate at a constant temperature. This is done under a certain water evaporation rate. We also consider the water vapor pressure through the specimen. From this data, we calculate the water-vapor resistance of the specimen.

Know more about thermal resistance and water-vapor resistance

Textile – Test standards for thermal resistance and water-vapor resistance.

-

GB/T 11048 covers testing thermal and water-vapor resistance under steady-state conditions. It uses the sweating-guarded hotplate test method.

-

ISO 11092 covers the effects of textiles on the body. It measures thermal and water-vapor resistance under steady-state conditions. Researchers use the sweating-guarded hotplate test for this purpose.

-

ASTM F1868 measures the thermal and evaporative resistance of clothing materials. It uses a sweating hot plate.

This hotplate is guarded by a sweating person. It is often called the “skin model” in this standard. It simulates the heat and mass transfer next to human skin. This test method works for all types of textile fabrics. It also works for coatings, leather, and multi-layer composites. Additionally, we’ve can share the ISO 11092 test methods and ISO 11092 PDFs as well.

Difference Between Thermal Resistance (RCT) and Water-Vapor Resistance (RET)

-

RCT: Thermal resistance determines if the fabric holds in heat. The higher the value obtained, the better the insulation. Rct (m²·K/W)

-

RET: Water-vapor resistance determines a fabric’s ability to allow water vapor (perspiration) to pass through it. The lower the value obtained, the more breathable the fabric. Ret (m²·Pa/W)

Perform Rct0, Rct, Ret0, and Ret tests on the TESTEX Sweating Guarded Hotplate TF129.

Why Choose Testex Sweating Guarded Hotplate TF129

Meet standards

All data for TF129 Guarded Hot Plate Apparatus meet the standard parameters, for example, ISO 11092 and ASTM F1868.

Consistency with international third-party laboratories.

Our test data aligns with results from renowned international third-party laboratories.

High reproducibility

The samples are the same, or the machines are the same model. After many tests, the Thermal Resistance and Water Vapor Resistance Test Results are consistently the same.

Longer service life

TESTEX builds robust prototypes for its Sweating Guarded Hotplates before moving to mass production. These prototypes must clear a rigorous Reliability Test, which involves pushing them to their limits under extreme conditions – intense temperatures, high speeds, and heavy loads. This testing guarantees a service life of at least 8 years.

User-friendly, transparent warranty policy

They come with a 14-month warranty. This is 2 months longer than the normal 12-month warranty. The extra time is for shipping. Besides, all spare parts have 3 months free warranty.

We support the full life cycle of the sweating-guarded hotplate TF129. We offer thermal resistance test equipment and services. Contact our service team for the Guarded Hot Plate Apparatus Price and Sweating Guarded Hotplate Test Method today!

5 reviews for Sweating Guarded Hotplate TF129

You must be logged in to post a review.

Why We Need the Thermal Resistance Test?

When people wearing clothes in cold or hot climates, the temperature of clothing, especially close-fitting, varies with the temperature of the skin. People should choose suitable clothes to ensure comfort, or at least in adverse weather conditions to protect the human body. The heat transfer property of fabric can ensure the comfort of clothing, for example, the clothing with high thermal resistance has a better function of preventing cold, while the clothes with low thermal resistance can give a cool feeling. Therefore, testing the thermal resistance of fabrics has an important reference for improving people's clothing comfort.

Thermal Resistance Test Principle

The sweating guarded hot plate instrument produced by our company adopts the constant temperature method. Place the sample to be tested on an electric hot plate which has good thermal insulation at all the other surfaces. Transfer heat to an electric heating plate so that it reaches constant temperature state, and test the heat needed to maintain the constant temperature of the electric heating plate. This method has been adopted by ASTM as the standard number ASTM D1518.

Sweating Guarded Hot Plate Test Method(Thermal Resistance Test Method)

Assemble the instrument, install SGHP software according to instructions, connect with thermal resistance instrument through network signal, and prepare for the test.

The RCT0 test is used to express the basic parameter of a machine. The value of Rct0 will be used to calculate the final RCT value of a sample. Rct0 test should be done when the machine stopped for a long time or the environment changed great.

Cut the sample as 50 cm x 50 cm, and pretreat it according to the standard requirements. Place the treated sample on the surface of the test area. If the thickness of the sample is more than 1 mm, then adjust the height of the wind speed sensor so that the height between the sample and the sensor is about 15 mm. According to the standard requirements to set the temp and humidity and then start the test until the testing environment is stable. Record the test results and calculate the final RCT values of the sample.

Daily Maintenance

1 Keep the machine clean: Clean the surface of the test plate and the dust of the air of exhaust grid by using the towel.

2 If the Ret test is finished and another Ret test will be run in next day, then open the safety cover and open the door of the conditioning chamber, the water will be evaporated from inside of the machine, and prolong the service life of the machine.

3 If the conditioning chamber will not be used for a long time, please drain off the water of the conditioning chamber.

The working principle of the Sweating Guarded Hotplate

The Sweating Guarded Hotplate is to evaluate the thermal resistance and water-vapor resistance of textiles. A waterproof and breathable film is placed on top of the hot plate, and a sample measuring 0.3m x 0.3m is placed on the film. Distilled water is fed from the bottom of the hot plate, and the surface temperature of the hot plate is stabilized at 35℃ to simulate sweating in the human body. The Sweating Guarded Hotplate is placed in an environmental chamber with a temperature of 35°C, humidity of 40%, and air flow rate of lm/s. When the system is in a steady state, the evaporative resistance of the fabric is calculated by equation (3): Ret = A(Pm - Pa)/(H - ΔHe)

Where Ret is the total evaporative resistance in m2·Pa/W; Pm is the saturated water vapor pressure on the surface of the test plate at the temperature of the test plate, Pa; P is the water vapor pressure of the air in the chamber, Pa; H is the heating power, W; and ΔH is the heating power correction term, W.

A: No, it is not equipped with this option.

Q: At what humidity ranges is the machine able to run?

A: The machine is not equipped with control humidity, but Temperature & Humidity Chamber can meet your needs, with its humidity range of 25%~85% R.H.

Q: What advantages does the machine have?

A: 1. It can contact with WIFI.

- The thermal resistance and Temperature & Humidity Chamber can be used separately. And other suppliers combine the two machines into one. They must be used together.

<start="3"> - Our Temperature & Humidity Chamber is made by a professional factory, which is more accurate. The ITS (Intertek testing service) bought this machine from a famous company, whose price is triple than ours. The test results from this machine are not precise because the machine is made by the company himself. Finally, he turned to us and bought a new one. We only do what we are good at.

Q: What kind of textiles need thermal resistance and water-vapor resistance tests?

A: The products have general thermal requirements. They include knitted underwear, cotton garments, quilts, and padding-like wadding. Some coated fabrics need water-vapor resistance testing. Coated fabrics are generally more resistant than ordinary fabrics. This affects the comfort of clothes.

The Sweating Guarded Hotplate Test shows how well fabric lets heat and moisture through. They show the warmth and moisture performance of the fabric. So, they help companies choose fabrics and position products.

Q: Is a Sweating Guarded Hotplate a Thermal Resistance Tester?

A: The Sweating Guarded Hotplate is a type of Thermal Resistance Tester, but it is not limited to measuring thermal resistance alone; it also measures moisture resistance (i.e., water vapor transmission resistance). Compared to a standard Thermal Resistance Tester, the Sweating Guarded Hotplate provides a more comprehensive evaluation of fabric comfort under real-life wearing conditions, particularly in terms of heat and moisture transfer. Therefore, the Sweating Guarded Hotplate is a more advanced thermal resistance testing instrument, commonly used in comfort studies for clothing, textiles, and materials.

Q: How to avoid the influence of air during guarded hot plate apparatus testing?

A: During testing, ensure close contact between the fabric and the test plate to avoid the presence of air pockets, as this can affect the accuracy of the test results.

Q: Why are the sweating-guarded hotplate test results unstable?

A: Variations in environmental conditions such as temperature, humidity, and airflow can impact the results. It's essential to maintain stable environmental conditions during testing and to calibrate the equipment.

Q: Why is the Water-Vapor Resistance (RET) of the test sample high?

A: Uneven surface treatment, excessive moisture absorption by the fabric, or improper placement of the sample can lead to a higher RET value. It is important to ensure uniform pre-treatment of the sample and to conduct the test according to standards.

Q: What parameters need to be controlled in thermal and water-vapor resistance testing?

A: Parameters that must be strictly controlled include the temperature of the test plate, ambient temperature, humidity, and airflow speed.

Q: In which fields can this machine be applied?

A: This Sweating Guarded Hotplate is widely used to evaluate the thermal insulation and moisture permeability of outdoor clothing, sportswear, bedding, and other products to enhance comfort.

Q: Why is the Water-Vapor Resistance (RET) Value low?

A: A low moisture resistance value may occur if the environmental humidity is too low or if the heating of the test plate is insufficient.

Q: What are the sampling requirements for thermal resistance and humidity resistance test - by using a sweating guarded hotplate?

A: Specimen thickness: When the thickness of the test sample is less than or not equal to 5mm, it should completely cover the surface of the test plate and the heat shield ring, and at least 3 specimens should be taken for each sample to ensure that the specimen is flat and wrinkle-free.

Multi-layer fabrics: Multi-layer fabrics should ensure that there is no air layer between the layers to avoid blistering and wrinkling.

Thickness Correction: When the thickness of the test sample is greater than or not equal to 5mm, the height of the test plate should be adjusted so that the upper surface of the specimen is flush with the test bench and corrected taking into account the heat loss at the edges.

jack ding –

This is the big investment for our lab, but it worth it, make our testing smooth and efficient

Adelaide Graham –

It’s worthy.

Mabel Electra –

Works perfectly, instruction manual was easy to read and understand.

Kyle Thompson –

That is very stable, and I like to communicate with professional staff like Lily.

testextextile –

Thanks. All staffs in TESTEX are professional.

Fanny Windsor –

The guarded hot plate apparatus price is reasonable and help us a lot.Recommend !