Auto Water Vapour Permeability Tester TF165B

The Water Vapour Permeability Tester is also called the Water Vapor Transmission Rate Tester (WVTR Tester). It measures the water vapor permeability of textiles and garments. It also measures it for coated fabrics, composites, sportswear, and industrial fabrics. This moisture vapor transmission rate tester complies with ASTM E96, GB/T 12704, JIS L1099, etc.

This machine tests vapor permeability. It can also test the Moisture Vapor Transmission Rate of medical protective clothing. We are a professional supplier of Auto Water Vapour Permeability Testers. Please feel free to contact us for a competitive price.

Description

Features of Auto Water Vapour Permeability Tester TF165B

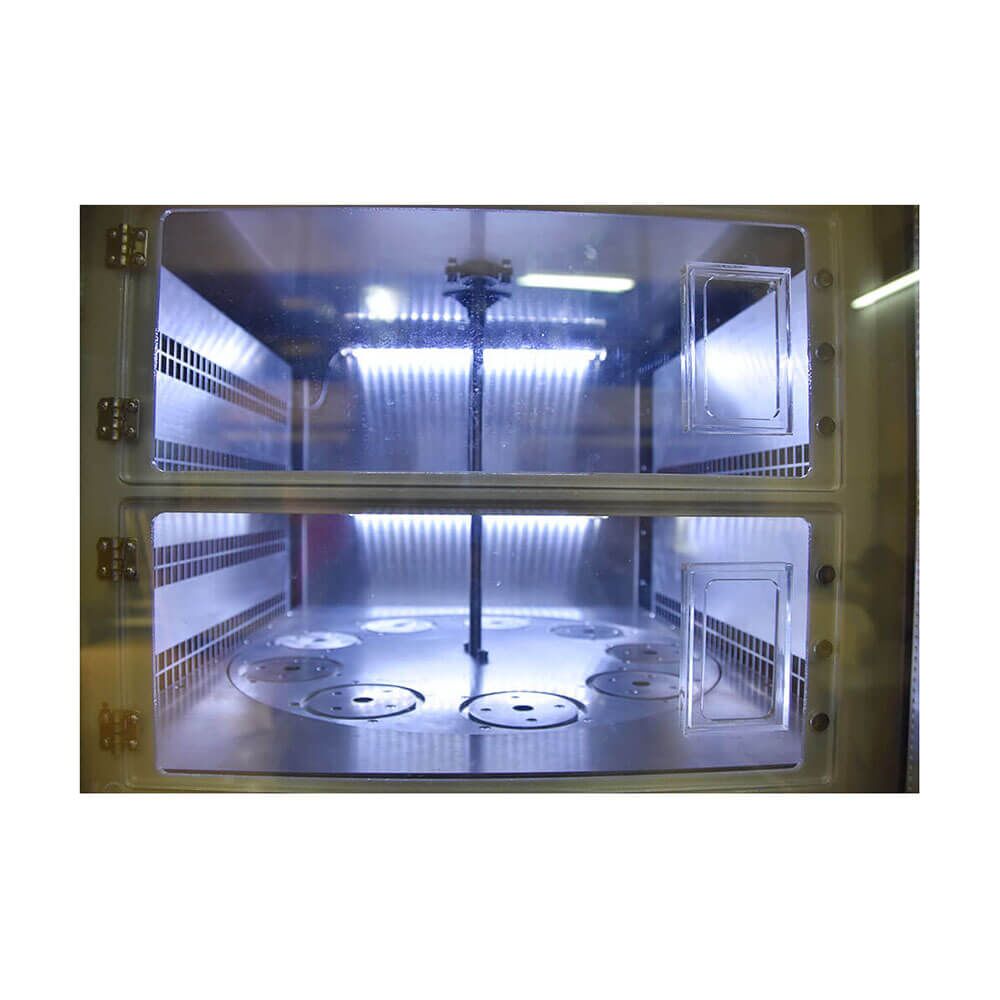

The water vapor permeability test results are more reliable. The test uses high-precision temperature and humidity sensors. It also uses a rotating sample holder with adjustable speed. This ensures that water vapor evenly affects each sample during the WVTR test.

It reduces cost and improves efficiency. It uses a double-layer rack with 9 test cups per layer. This setup boosts water vapor permeability test samples by a large margin.

The holder of this WVTR Tester is designed with two small doors for sample putting. This avoids impacting the test environment after opening the door. The WVTR tester also has automatic water filling for long-term testing.

It is easy to operate. The WVTR tester has chip control and color touchscreen operation. It also has a modular design and intelligent control. It displays water vapor permeability test time in real-time. All of these features contribute to a perfect performance water vapor permeability tester.

Application of Auto Water Vapor Permeability Tester TF165B

Waterproof and Moisture-permeable fabrics are more and more popular. It keeps the sweat from building up and condensing between the body and the fabric. It keeps the garment comfortable. It is a high-tech and unique functional fabric. Waterproofing is easy for normal fabric. The key is to improve water vapor permeability. The water vapor transmission rate testing is becoming increasingly important in textiles.

The TF165B is an Auto Water Vapour Permeability Tester. It measures the water vapor permeability of fabrics. It works on many fabrics. These include coated ones that let moisture through, as well as wadding tires, space cotton, and other nonwoven garment fabrics.

The fabrics are waterproof and let water vapor through. They are used to make military and protective clothing. Now, they are widely used to make sportswear, travel bags, tents, etc. Waterproof, vapor-permeable fabrics can also be used as trauma dressings. They are like cotton gauze. They keep wounds dry. They are also used as surgeons and dustproof work clothes in the clean studio.

Specifications of Auto Water Vapour Permeability Tester TF165B

- Airflow speed: 0.1 ~ 0.8 m/s

- Temperature: 18 ~ 50°C ± 0.5°C

- Humidity: 40% ~ 95%

- Power: 220 V 50/60 Hz 4500 W

- Weight: 320 Kg

- Dimensions: 880 x 700 x 1760 mm (L x W x H)

Standards of Auto Water Vapour Permeability Tester TF165B

- ASTM E96: Standard Test Methods for Water Vapor Transmission of Materials

- GB/T 12704: Textiles-Test method for water-vapor transmission of fabrics-Part 1: Desiccant method

- JIS L1099

Test Principle of Water Vapor Transmission Rate Testing.

In a constant temperature and humidity test room, we place the permeable cup. We put the specimen in the cup and sealed it with a rubber gasket. We then place the permeable cup with water and fabric in the sealed room. The room has the specified temperature and humidity. We calculate the permeable amount by measuring the change in the cup’s quality. The cup includes the specimen and moisture absorbent or water. This change occurs within a certain period.

Why Choose TESTEX Auto Water Vapour Permeability Tester TF165B

Strictly meet standards

All data for the TF165B WVTR testing machine meet the standard parameters.

Consistency with international third-party laboratories

The water vapor permeability test data are comparable to the WVTR test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples and the same WVTR tester, after multiple tests, the results of water vapor transmission rate testing will remain consistent.

High reproducibility

The same set of samples, and different machines of the same model, after multiple WVTR tests, the results will remain consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in complicated environments to ensure the expected service life.

User-friendly transparent warranty policy

Water Vapor Permeability Tester TF165B, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Auto Water Vapour Permeability Tester TF165B. So feel free to contact our service team with any questions.

Welcome to TESTEX – a professional textile testing instrument supplier – Auto Water Vapour Permeability Tester TF165B is on sale, contact us for a detailed price quote.

5 reviews for Auto Water Vapour Permeability Tester TF165B

You must be logged in to post a review.

What is the Water Vapour Permeability of Fabric?

Water vapor permeability definition: In general, there is a water vapor pressure difference between the front and the back of the fabric, so the water vapor diffuses from the high-pressure air side to the low-pressure airside through the fabric. The water vapor permeability of fabric refers to the difficulty degree of water vapor passing through the fabric. The water vapor permeability of fabric is an important index to measure the comfort of clothing. Due to the difference of clothing environment, it is necessary to choose the appropriate water vapor permeability test method.

The Principle of Water Permeability Test

A test specimen is sealed over the open mouth of a test dish that contains water, and the assembly is placed in a controlled environment. Following a period of time to establish the equilibrium of the water vapor pressure gradient across the sample, successive readings of the assembled dish are made and the rate of water vapor permeation through the specimen is calculated.

How to Calculate Water Vapor Transmission Rate?

The water vapor permeability index is calculated by expressing the water permeability of textiles as a percentage of the water vapor permeability of a reference fabric which is tested in a water vapor permeability test. After the water permeability test for the fabric, the water vapor permeability of the fabric can be obtained according to the water vapor permeability unit conversion and the water vapor permeability formula.

A1: Water Vapor Permeability (Breathability) is the ability of a fabric to allow moisture vapor to be transmitted through the material. It is an essential contributing property to thermal and Physiological Comfort clothing, and is vital in filtration and medical textiles.

Q2: What is water vapor transmission rate testing (water permeability test for fabric)?

A2: This blog concludes more information about water permeability. You can find it here.

Q3: What is a good mvtr? And what is a perfect mvtr?

A3: For the moisture transmission rate (also known as Moisture Vapor Transmission Rate, MVTR) of textiles, the definitions of satisfactory and excellent differ for different applications and standards. Generally speaking, MVTR indicates the amount of water vapor allowed to pass through a textile within a certain period of time and is expressed in g/m²/24h. Below are some reference standards:

Moisture Permeability Standards for General Garments and Textiles:

General Clothing:

Qualified moisture permeability: 2000-5000 g/m²/24h.

Excellent moisture permeability: 5000-8000 g/m²/24h or more.

Outdoor clothing (e.g. mountaineering, skiing clothing):

Qualified moisture permeability: above 5000 g/m²/24h.

Excellent moisture permeability: above 10000 g/m²/24h.

Waterproof and breathable materials (e.g. Gore-Tex, eVent, etc.):

Qualified moisture permeability: > 15000 g/m²/24h.

Excellent moisture permeability: > 20000 g/m²/24h.

Influencing factors:

Usage: Moisture permeability standards may vary depending on the usage of the textile (e.g. sportswear, outdoor equipment, daily wear).

Environmental conditions: Temperature, humidity, and other environmental conditions will affect the test results.

Fabric structure and processing: Different materials and finishing techniques (e.g. coating, lamination, etc.) can significantly affect the moisture permeability.

In summary, specific moisture permeability requirements should be determined based on the end use of the textile and industry standards.

You can use a water vapor permeability tester to do the test.

Q4: How many kinds of Water vapor permeability test methods?

A4: The following three methods are more common and practical:

1. Cup Method (Desiccant Method)

Principle: The test sample is covered with a cup containing desiccant or water, which is sealed and placed in an environment of constant temperature and humidity. Water vapor penetrates or escapes from the surface of the sample into and out of the cup, and the weight of the cup changes over time.

Calculation of the Water Vapor Transmission Rate: The Water Vapor Transmission Rate (g/m²/24h) is calculated by measuring the change in weight of the cup over some time.

Advantages: Easy to operate, suitable for different types of materials.

Disadvantages: Longer testing time and high environmental control requirements.

2. Water Vapor Transmission Rate Tester (MVTR Tester)

Principle: Using a specialized testing instrument, the sample is sandwiched between the wet and dry zones, the wvtr testing machine automatically controls the humidity difference and measures the moisture permeability by means of a sensor.

Calculation of Moisture Transmission Rate: The instrument automatically calculates the moisture transmission rate based on the humidity difference between the two sides of the sample and the amount of water vapor passing through.

Advantages: High precision, fast testing speed, suitable for different materials.

Disadvantages: Expensive equipment, complicated operation.

Test conditions:

Temperature: The standard test temperature is usually 23°C, but sometimes tests are conducted at different temperatures such as 38°C, 50°C, and so on.

Relative humidity: usually tested at 50% or 90% relative humidity.

3. Infrared Humidity Sensor Method (Infrared Humidity Sensor Method)

Principle: The test sample is placed between two chambers of the humidity sensor. One chamber is filled with moisture and the other is dry. Water vapor passes through the sample from the wet chamber to the dry chamber and the sensor detects the change in humidity in the dry chamber.

Water Vapor Transmission Rate Calculation: Using the sensor data, the rate at which water vapor passes through the sample is calculated.

Advantages: Faster testing, suitable for large-scale testing.

Disadvantages: equipment is more expensive, suitable for thin or have a certain degree of moisture permeability of the material.

Related Standards:

ASTM E96: describes a variety of standard methods for testing moisture permeability by the cup method.

ISO 15496: specifies test methods for water vapor permeability of textiles.

GB/T 12704 (China National Standard): Specifies the test methods for moisture vapor transmission rate.

Each method has its own advantages and disadvantages, and the selection of a specific method needs to be weighed according to the nature of the textile and the actual application scenario.

Q5: Which textiles need water vapor transmission rate testing?

A5: Moisture permeability testing is mainly applied to textiles with strict requirements for breathability, comfort, and protection.

The following are some of the types of textiles that must be tested for moisture permeability:

1. Functional clothing fabrics

Outdoor clothing: Mountaineering clothing, skiing clothing, assault clothing and other outdoor sports clothing need to have good waterproof breathability to ensure that the wearer can sweat and stay dry during exercise.

Sportswear: running clothes, fitness clothing, etc., requires good moisture permeability to help dissipate heat and sweat, and enhance sports comfort.

2. Waterproof and breathable fabrics

Waterproof jackets and pants: functional fabrics such as Gore-Tex, eVent, etc. need to be both waterproof and breathable to provide good outdoor protection.

Protective Clothing: Certain specialized occupations (e.g., firefighters, chemical processing workers) require protective clothing with excellent moisture permeability to keep the body dry and comfortable, and to avoid excessive sweltering.

3. Medical Textiles

Medical protective clothing: including surgical gowns, isolation gowns, etc., which are required to protect against liquid penetration, but also breathable, to reduce the discomfort caused by prolonged wear.

Medical dressings: such as breathable bandages, etc., not only to prevent moisture or bacteria into the wound, but also to allow the skin to breathe.

4. Home textiles

Bedding: such as waterproof and breathable bedspreads, pillowcases, etc., especially for infants and young children or the elderly use of products that need to be waterproof and at the same time maintain breathability to avoid moisture accumulation.

Cushion and sofa fabrics: some household fabrics require good moisture permeability to ensure comfort.

5. Industrial textiles

Filtration materials: textiles used for air or liquid filtration require both prevention of particles or liquids from passing through and a certain degree of breathability to maintain filtration efficiency.

Tent and awning materials: textiles used for outdoor activities or temporary tents and other textiles that are both waterproof and have good breathability to avoid stuffy heat and humidity inside.

6. Shoe materials

Waterproof and breathable footwear materials: such as outdoor shoes and sports shoes, the moisture permeability of the upper can enhance wearing comfort and help keep the inside of the shoes dry.

7. Baby and nursing supplies

Diapers and hygiene products: good moisture permeability is needed to prevent discomfort or health problems caused by prolonged exposure of the skin to moisture.

Baby carriers: fabrics that come into contact with the baby's skin need to be breathable to ensure the baby's comfort.

8. Military and Specialty Protective Equipment

Military clothing and equipment: Military equipment usually needs to have good Water Vapor Permeability to ensure the comfort and protection of soldiers in different environments.

These textiles have stringent requirements for Water Vapor Permeability in use scenarios, so water vapor transmission rate testing is a necessary step to ensure that they meet performance standards.

For more information about water vapor permeability tests or water vapor permeability testers, welcome to contact us.

Esther Adams –

Works great, and comes with lots of accessories.

Jerry Brewster –

I recommend the best water vapor permeability tester suppiler to you all.

Charles Mansfield –

Excellent water vapour permeability tester! I will come back soon.

Arthur Acheson –

The manufacturer of this water vapor permeability tester is so kind. 5 stars!

Isabelle –

Good , seller bring it fast