Now, mask factories in European and American countries are facing some pressure: on the one…

How to avoid the trap of mask making machine market?

As the global epidemic intensifies and spreads, now the world is building a large number of new mask production lines to solve the problem of mask shortage. However, many mask production lines are transferred from other manufacturing industries, whether procurement or production links, they underestimate the technical of mask production and easily fell into the trap.

What are the routines and traps in the mask making machine market?

1 Receive a large number of orders, productivity was not up to date or the supply of spare parts was insufficient, the promised delivery period cannot be fulfilled and had to be postponed.

2 Underestimates the production difficulty of the mask making machine: the crude manufactured workpiece, the installation debugging is not smooth, or the machine is very easy to run out of the situation. At present, there are less than 15% of mask making machine that can work normally on the market.

3 Prices continue to rise, the stock assembly and commissioning directly sold at a high price without preferential supply to the contracting party.

4 The product configuration of the mask making machine purchased is not correct and the function gap is large. However, because there is no specific product configuration stated in the contract, so it is difficult to safeguard rights.

5 The manufacturer of the mask machine is not qualified or the technology is not up to standard, it is difficult to meet the relevant quality standards, not up to the requirements of sale.

6 Take the drawing and dare to take the order, replenish the parts, follow the trend and speculate more, and do less.

7 In addition to hardware constraints, there is also a lack of manpower for the installation, commissioning and daily maintenance of the mask making machine.

Why are there traps?

Mask making machine belongs to specialized production, involving many parts, raw materials, technical reserves and qualification standards, understand all, is not much easier than the production of other products. The stock of mask making machine is not many, the delivery before the epidemic is basically about 2 months, now in an extraordinary period, Chinese manufacturing overtime work, 20~30 days for delivery, which directly led to the stock tight, the phenomenon of following the trend and speculating is very much.

The agreed delivery date is delayed. Get equipment friends, slow debugging bad. Debug out the product, but can not achieve the expected capacity. The real truth is that most of the new factories are holding the same set of automatic mask equipment drawing, copying the working, the results can be imagined.

How to avoid the trap during the purchase of mask making machine?

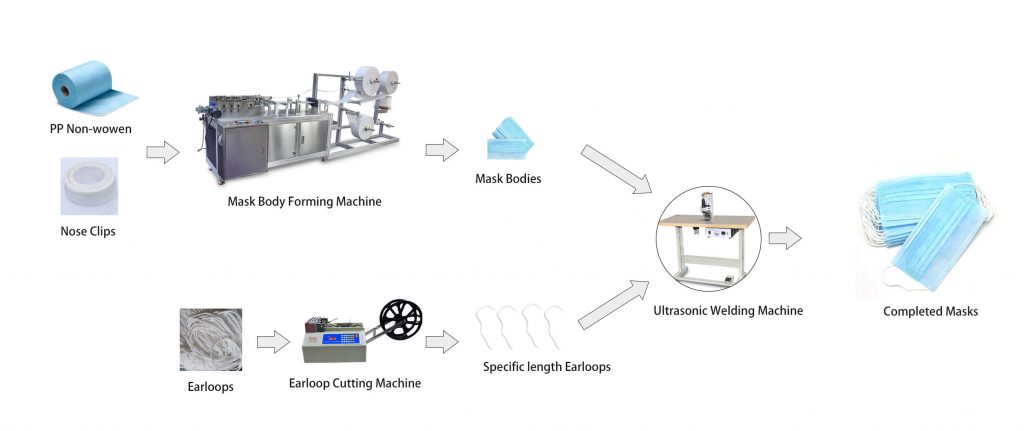

The production of mask making machine needs three stages, the first is spare parts production, the second is assembly, and the third is machine debugging. At present, the first two items, most of the mask manufacturers have no problem, but debugging requires experienced engineers, so restricting the production capacity of the mask making machine.

Pay attention to the fact that the lack of industry experience will affect the operation and maintenance of the production line due to the neglect of details, and the after-sales service of the manufacturer can not keep up. When purchasing a mask making machine, please refer to the following points:

1 Selection of automation experience, shipping experience manufacturers, the video sent is not important, to have video links or field visits.

As demand soared, many of the original mechanical, electronic components companies began to follow suit to produce mask making machines, but most factories do not have the ability to develop and mechatronics. At present, no more than 15% of the mask making machines made in the market can run steadily.

It is recommended that video links or field visits, the mask making machine can run at least a day will be more reliable.

2 If you can buy second-hand old equipment, use the old equipment first if you can buy semi-automatic equipment, buy semi-automatic equipment first.

| Type | Rate of production | debugging | Remarks |

| Automatic mask making machine | Theory: 90~110pcs/min

Reality: 80~90pcs/min |

Hard to debug,

run unstable |

Two workers, the daily output is 80,000~100,000 |

| Semi-automatic mask making machine | Theory: 110~130pcs/min

Reality: 120pcs/min |

Easy to debug,

run stable |

Several people to weld the earbands, the daily output is about 170,000. |

3 The masks produced should conform to the relevant national standards and meet the requirements for sale.

Without the production and quality control experience of the mask industry, the masks produced may not meet the standard. Failure to understand the production process or design unreasonable will lead to production interruption, high scrap rate.

Masks are protective appliance, quality testing is very important, to have professional mask testing instruments to ensure that the mask making machine can produce masks that meet the quality standards. Common test standard for masks are: YY/T 0969, BS EN14683, ASTM F2100, ASTM F2101, YY 0469, ISO 22609.

4 Don’t believe that short delivery time, low price, these are all routines.

| Date | Market condition of automatic mask making machine |

| Jan. 20th | Chinese Spring Festival, masks were snapped up, and the mask making machine cost 30,000USD, few people realize of investment. |

| Feb. 10th | Start work, the mask machine has only a small stock, about 43,000USD, but most people are hesitant to wait and see, few people order the machine after 30 days |

| Feb. 25th | A lot of manufacturers start to pay the order, the price is about 65,000USD, 25~30 days delivery. |

| Mar. 1st ~ Mar. 4th | New machines stock were snapped up by 120,000USD~200,000USD, more manufacturers order 30~35 days delivery machines for 80,000USD~90,000USD. |

| Mar. 5th ~ nowadays | 15~20 days delivery machine is 90,000USD, 30 days delivery machine is about 85,000USD. |

Because the automatic mask making machine is difficult to debug, unstable operation, the normal delivery period is close to 2 months, many automatic mask machine manufacturer to grab orders, often bragging the delivery less than 20 days and the price less than 90,000USD, resulting in many factories to buy automatic mask making machine, delay to receive the machine, get the machine, slow debugging. Even if the machine can be debugged, it can not achieve the expected capacity due to unstable operation or produce masks that do not meet the standard quality.

TM120 semi-automatic mask making machine does not have to worry about these problems at all, the debugging is simple and the operation is very stable. The most important thing is that delivery is possible in 7 days, which is about one month earlier than the automatic mask making machine, with this time, you will have one more month’s output, what are you still waiting for?

5 Choose manufacturers with export experience who can provide perfect after-sales service.

Dongguan, in China, is the production base of mask making machine, fewer export manufacturers, and fewer manufacturers with perfect after-sales system. During the epidemic period, after-sales personnel can not be sent to install and train, and buyers can not come to China for training. In addition, the export of mask machine involves the outer packaging materials, the production of export documents, logistics and customs clearance arrangements, a little carelessness the goods may be detained by the customs inspection, less than 10 days more than 30 days.

Choose manufacturers with export experience who can provide perfect after-sales service, so that the machine can be safely, quickly, low-cost delivery to the customer, to ensure that the customer can quickly master the machine debugging and use rapid production.

6 Choose a reputable manufacturer, the mask making machine is not a one-off deal.

Choose international authority certification manufacturers, such as whether there is SGS certification, whether to pass the ISO quality management system and so on. TESTEX is a national high-tech enterprise with experience in automated production and R&D, with ten years experience in import and export trade and perfect after-sales service system. 90% of the TESTEX brand instruments are sold to European, American and Asian countries. The customers include NASA, ITS, SGS and so on. You can compare these aspects.

If you think the article is helpful, you can share it with your friends to help more people not fall into the trap of buying mask making machine.

This Post Has 2 Comments

Leave a Reply

You must be logged in to post a comment.

I am looking for a machine to make masks and I require 5mm welding and that the shipment of the machine is tax free I am in Matamoros Tamaulipas Mexico

Hi Narcizo, Our sales engineer will contact you soon, thank you for your comments.