Now, mask factories in European and American countries are facing some pressure: on the one…

Mask Making Machine – The Pros and Cons of On-site Inspection

What is the mature and reliable commissioning of mask making machine? This is the question that many friends need to think about when purchasing face mask making machine, the market has been from the initial madness to the current rational, everyone has become cautious, so how can you be more secure in purchasing to the mask making machine? Today I’m going to talk about those things that are part of the acceptance and commissioning of the mask making machine and provide you with a reference.

1 From the crazy in pursuit of profit of mouthpiece machines to the helplessness of switching to face masks

Let’s take a look at some relevant data. China produced 20 million masks per day before the epidemic and 200 million masks per day after the epidemic. Despite a tenfold increase in production capacity, it still cannot meet the huge demand of the global market.

The first phase, in February, the outbreak of the epidemic in China, the market of face mask, and mask making machine was triggered, the huge demand drove the market for a short period of frenzy. However, due to the difficulties of commissioning the mouthpiece machine, the reality is that many manufacturers have only done a trial of the equipment out of the factory, countless technically unsatisfactory manufacturers bought the machine does not produce the energy and heavy losses. At present, the equipment factory is also facing returns from the national manufacturers, and eventually, the talent of both empty, both losses, the front short-term wealth instantly disappeared, and even some people lost all assets. Most people who enter this market are losing money.

The second phase, which began around the end of March, saw the outbreak begin worldwide, and to date (23 April), the number of people infected with the new 2019-nCoV worldwide has reached more than 2.6 million, affecting almost all countries and populations. As a result of the epidemic, the business of other industries has continued to decline, and everyone is thinking of saving themselves, and manufacturers of various types of equipment have begun to switch to the production of epidemic prevention materials. At present, many customers are seriously out of stock, a large number of foreign orders to China, in this case, in front of those who are afraid to become cautious, the purchase of the mask making machine will pay great attention to the field inspection link.

2 Mask making machine purchase: on-site inspection means that the debugging is really good?

2.1 The sting of on-site inspection

The first stage of the madness led to the aftermath, so many people are very cautious about choosing the mask making machine, so there are, at present, all purchasers as long as the spot, they bring the technical staff on the spot to see the mask making machine, pick up the goods on the spot, every day hear who has the spot, immediately rush over, sincerely not easy, the manufacturer is hard, the purchaser is also hard.

So, what are the pros and cons of field trials, field inspections? Based on my relevant experience, the analysis is as follows:

2.2 Analysis of the pros and cons of on-site inspection

Benefit 1: The spot machine was taken away immediately if the payment, not afraid to pay the money and not get it.

Benefit 2: Seeing the trial operation process, the technical staff review the machine, so that the buyer has the confidence to pay for the goods on-site.

Benefit 3: The technician knows the machine well, can easily calculate the cost, give advice to the buyer and negotiate for the lowest price.

To make the drawbacks clear, we need to understand the facts of mask making machine debugging first. During the production of face masks, various problems can be encountered (e.g. material differences, fit of accessories, etc.), which can affect the stability of the mask making machine in mass production. Therefore, the manufacture of mask machines requires stereotypes.

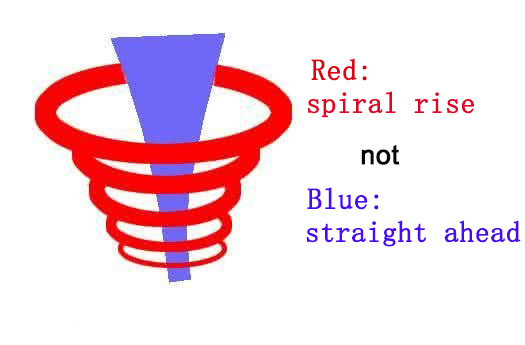

What is stereotyping? We first make a prototype machine, then start mass production testing, constantly find production problems, debug and improve, and finally determine the model, mass production of the machine, before the factory sales, reduce after-sales problems. The shaping of mask making machine is like a spiral of repeated ascent that takes a certain amount of time to accumulate to be stable enough, not to be able to fall into place in one step.

If these problems have been debugged by the supplier before leaving the factory, then the more stable the mass production of this machine, if these problems have not been checked one by one, then even if you site inspection, the machine can run steadily, when you pull back to produce the mask, sooner or later these problems will be exposed.

Cons 1: Currently in the temptation of high cash profits, equipment owners are both afraid of their own slow, customer loss, but also afraid of the sudden collapse of the market and their own pre-investment can not be recovered. With multiple layers of factors, no longer do mass production testing, and immediately after the trial shipments to receive payment, reducing their own risk. This is just like vaccine research and development, it’s not even clinical trials before it’s made, and the users are just lucky and have their own technical strength at a later stage. The technically strong spend days or even weeks to solve the mass production problems, the technically weak machines directly strike, and the manufacturers to pull the skin and fight the lawsuit. There is a time cost here, an opportunity cost that most purchasers do not consider.

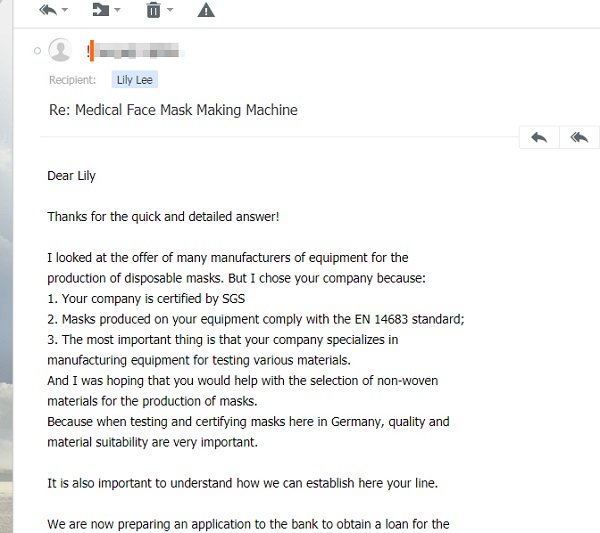

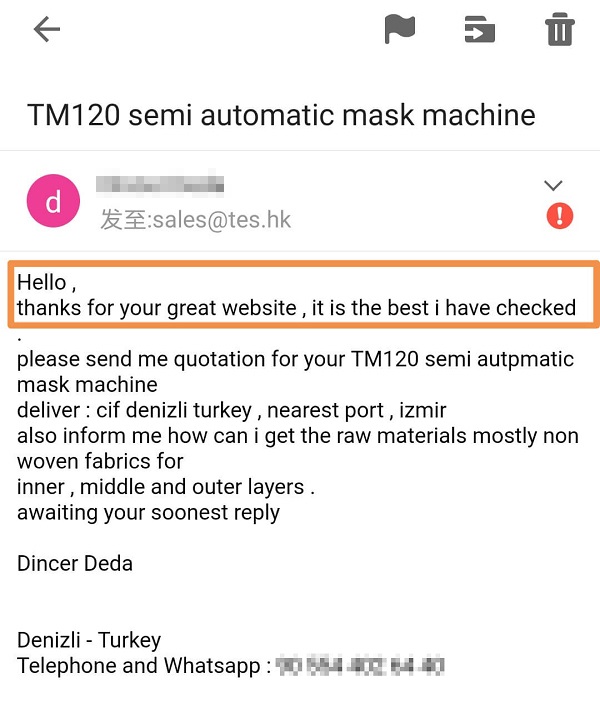

Take our mask making machine TM120 of TESTEX as an example: from the digestive drawing, production assembly, trial and commissioning, mass production trial, before and after, the company from the boss to the technical dozens of people, every day from 7 a.m. to 12 a.m., and then ask for help from outside experts, before and after has spent a month, scrapped hundreds of thousands of materials and materials, every day is still improving, strive for perfection, really not easy. There is always a reward for the effort, and when we receive recognition from our customers, the effort is worth it.

Cons 2: Time is money, the structure of the mask making machine, if there is no problem, debugging soon, immediately put into mass production, but if the machine has a guarantee, only do a trial, the machine has a high probability of problems, once the problem, you may invite experts to debug is useless, unless the ability to change the machine, but the time and opportunity cost all gone.

Cons 2: Time is money, the structure of the mask making machine, if there is no problem, debugging soon, immediately put into mass production, but if the machine has a guarantee, only do a trial, the machine has a high probability of problems, once the problem, you may invite experts to debug is useless, unless the ability to change the machine, but the time and opportunity cost all gone.

Cons 3: The confusion of the market, has seen many manufacturers, each boss boasts of their own equipment world-class, and finally, the buyer produces a selection disorder, the right to choose to purchase on the technical staff. But what the technician understands is the equipment, and here, in addition to the equipment itself, the time cost, opportunity cost, return on investment, these are strategic issues, it is the boss who decides. Once the boss has a choice dilemma and cannot rationally analyze the pros and cons, the issue of strategic direction can result in a total loss, with the final loss being paid for entirely by the boss and shareholders.

The purchase of the mask making machine to the site inspection, of course, can improve the quality of our decision, but we should also note that we can not make decisions based only on the on-site operation of the machine. Knowing what’s going on, and all the more so, only then, can choose the most reliable mask making production line.

face masks supplier: www.testextextile.com/product/medical-face-mask

mask making machine supplier: www.testextextile.com/tm120-medical-mask-production-line

This Post Has 0 Comments