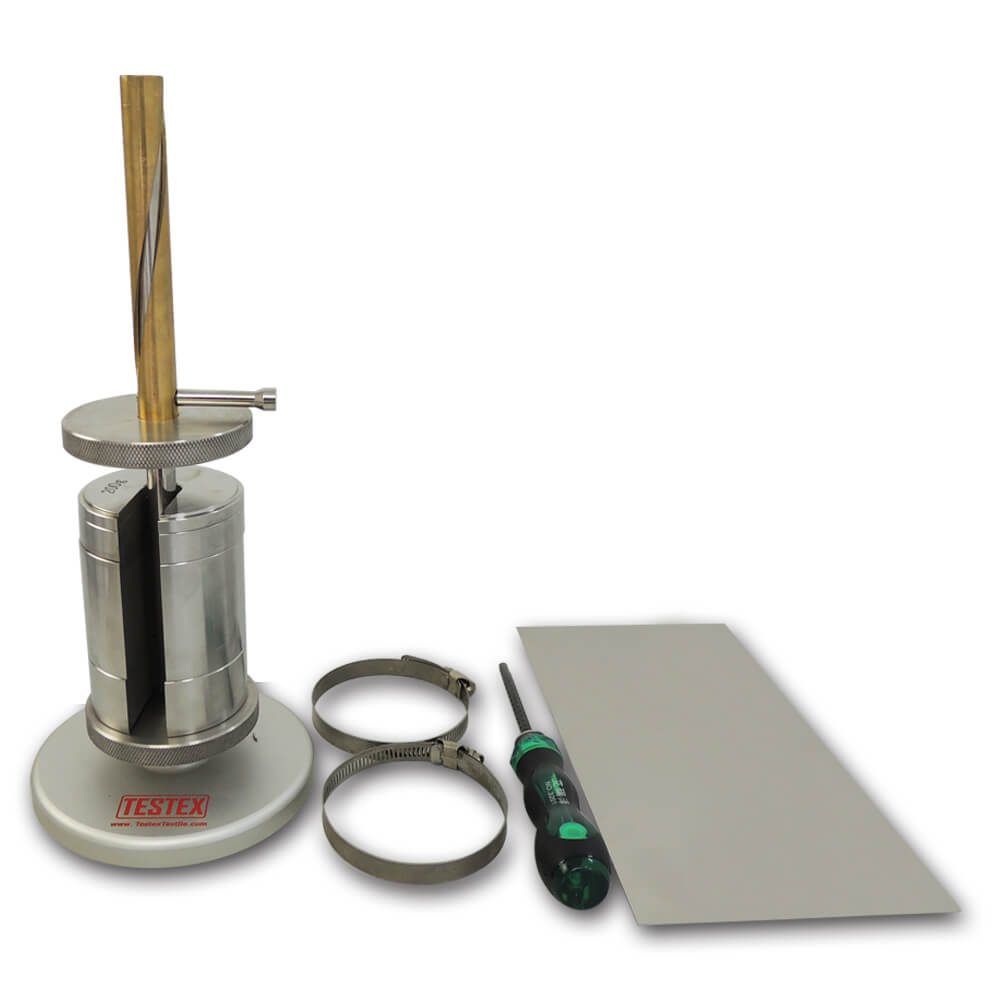

AATCC Wrinkle Recovery Tester TF112

AATCC Wrinkle Recovery Tester is used for determining a fabric’s ability to recover after wrinkling under a pre-determined load for a set period of time.

Description

Application

AATCC Wrinkle Recovery Tester is used for determining a fabric’s ability to recover after wrinkling under a pre-determined load for a set period of time.

A set of 5″x3″ dimensional plastic replicas is offered on request to grade the test samples 1 ~ 5.

Standard Accessories

Weight

Sampling plate

Optional order

AATCC Wrinkle Recovery Tester Plastic Replicas (Set of 5)

Dimensions Φ150 x 330 mm (L x W x H)

Weight

| 5 kg |

Dimensions

| φ | 150 mm | * | 330 mm |

Standards

| Standards | AATCC 128 | ISO 9867 | M&S P123 |

| Optional standard | ENKA 3061 |

4 reviews for AATCC Wrinkle Recovery Tester TF112

You must be logged in to post a review.

Why Do We Need to Test the Wrinkle Recovery of the Fabrics?

In the process of wearing and keeping the fabric, because of the external forces, such as folding, shearing, compression, bending and washing, it is difficult to return to the original level state even after removing the external force. This phenomenon is called wrinkle. Wrinkle not only seriously affects the appearance of fabric, but also leads to severe wear along the crease or wrinkle direction, which accelerates the damage of fabric. Therefore, crease recovery is one of the important indexes to evaluate the fabric’s properties.

Test Principle

Fabric wrinkle recovery instrument is used to test the recovery ability of fiber fabric samples under a certain load after bending for a certain time. Under the condition of standard atmospheric pressure, apply a predetermine pressure to the sample with the standard wrinkle device and keep the time set. The pressurized sample will produce uniform deformation through the whole structure of the instrument and the precise spiral column. Then the sample is compared with the standard sample and rated.

Sample Preparation

Cut three samples, 150mm * 280mm each. These should be cut with the long direction running in the warp or the wale direction of the fabric.

At 21±1℃ and 65±2% humidity, each sample remained at least 8 hours in the state.

Testing Procedure

1 All tests were performed at the environment of 21±1℃ and 65±2% humidity.

2 Raise the top flange of the recovery tester and fix it to the top of the tester with the lock pin.

3 Wrap one long edge of a pre-conditioned test specimen around the top flange of the wrinkle tester, with the face of the specimen on the outside. Fasten the specimen in position using one of the strips of Velcro.

4 Wrap the other end of the specimen on the flange, and then wrap the second piece of Velcro around the bottom of the specimen so that it forms a “closed tube” of fabric.

5 Adjust the bottom edge of the specimen so that it lies smoothly without sagging between the top and bottom flanges.

6 Withdraw the locking pin and lower the top flange gently with one hand until it comes to rest.

7 Immediately place a total mass of 3500 grams (all three weights) on the top flange and record the time.

8 After 20 minutes, remove the three weights and raise the top flange, carefully avoiding altering any of the induced wrinklings.

9 Clamp the short edge side of the sample with a clip and hang the sample on a hanger, so that the length direction of the sample is perpendicular to the ground.

10 After 24 hours in this conditioned atmosphere, take down the sample and rate it.

As a professional supplier of textile instruments, we are committed to continually improve the user experience, TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

[contact-form-7 id="16355" title="Inquiry"]

Joseph Kathleen –

The price and quality of the products are very good. I will buy again.

Magee Gladstone –

Excellent. Works perfectly and was received on time

James –

I’m satisfied with it and I will recommend it to my friend who also need it.

testextextile –

Thank you very much.

Zona –

Great seller, great product = recommend! Super fast shipping!