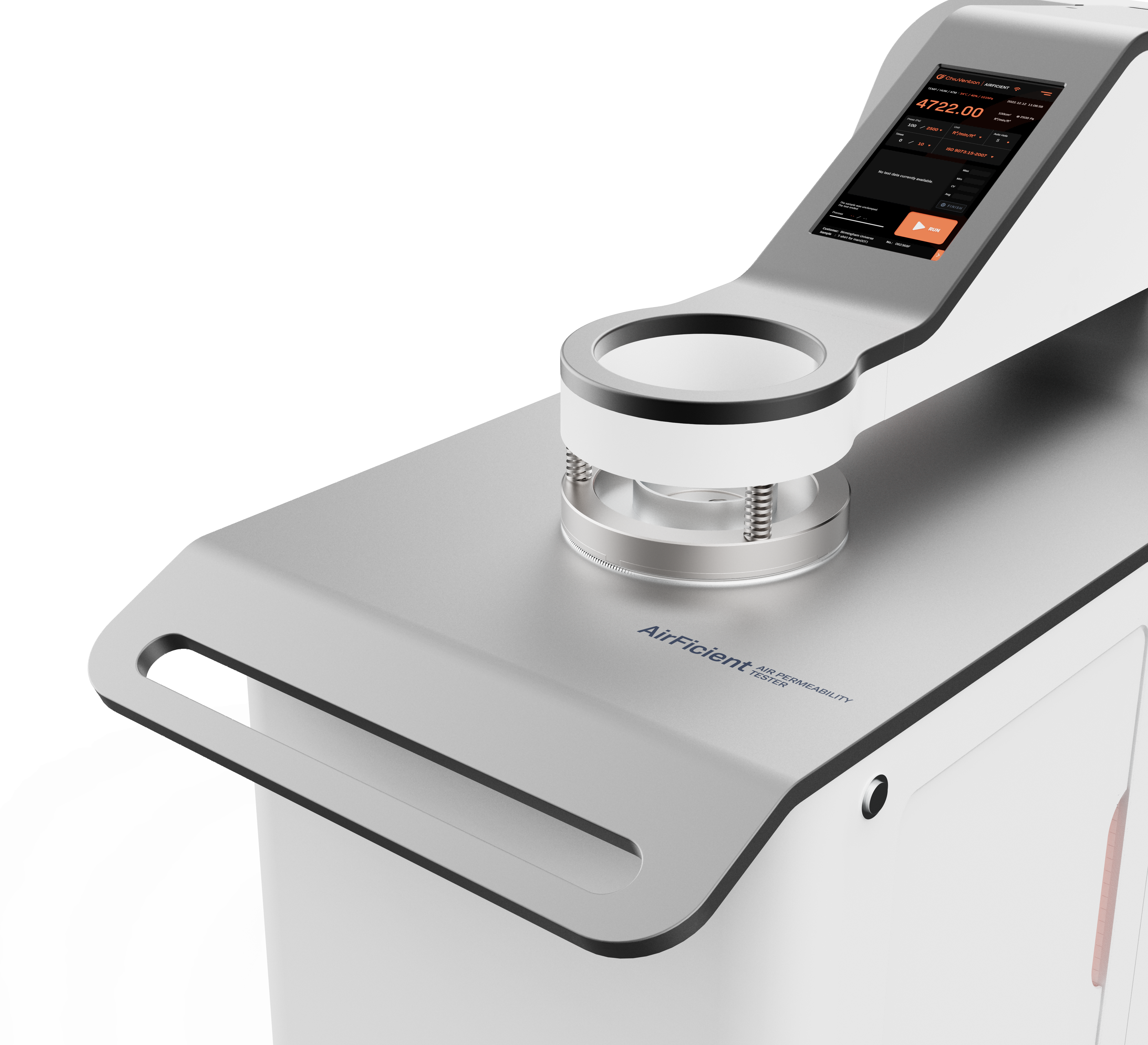

Air Permeability Tester | A smart instrument developed by the sister company ChiuVention.

Our Air Permeability Tester gives you fast, reliable air permeability test results. This smart instrument allows you to set parameters and monitor air permeability test procedure via smartphone, boosting efficiency.

Designed for versatility, this permeability apparatus is suitable for a wide range of materials, including technical textiles, non-woven fabrics, sponges, paper, and other breathable materials.

This Air Permeability Tester for Textiles adheres to multiple international standards, ensuring compatibility with various air permeability testing requirements. It applies to standards such as GB/T 5453, ISO 9237, ISO 9073:2015, JIS L1096 Item 8.26 Method C, BS 3424-16, BS 6F 100 3.1, NWSP 070.1.RO(15), and GB/T 24218.15, making it ideal for global textile manufacturers and research institutions.

The air permeability method involves directing air through the fabric sample, creating a pressure difference between the front and back surfaces. The amount of air that passes through the fabric under a specific pressure difference is measured, providing a precise air permeability value. The method measured on this machine allows for accurate air permeability calculation.

Description

Features of Air Permeability Tester

Tests are easy and fast.

The Air Permeability Tester is user-friendly, allowing you to choose the test standards and measurement units directly from the operation screen. The instrument automatically detects the various ranges of the test fixture head, enabling you to initiate the permeability test and receive results instantly.

Self-designed calibration system ensures accurate testing at all times.

The calibration system has undergone third-party testing, confirming its reliability and authority, which allows users to conveniently calibrate the instrument whenever needed.

More reliable test results

Our innovative test model features maintenance-free range conversion components that eliminate loss, providing high repeatability and reliability in air permeability test results. Additionally, the use of high-quality core components, including pressure sensors from well-known brands, further enhances the accuracy of these results. Canada Goose (Canada headquarters) and the world’s No. 1

electric car brand (USA) uses the instrument for testing automotive interiors.

Smart instrument

You can connect the Air Permeability Tester with the SmarTexLab App installed in smartphones through Wi-Fi. This connection enables you to set parameters, monitor the test status, receive equipment warning reminders, and share air permeability test results with the quality control department or brand buyers. This function also makes the air permeability test for fabric more efficient and transparent.

Application of Air Permeability Tester

The Air Permeability Tester is essential for assessing the resistance of various textiles to air passage, including woven, knitted, non-woven fabrics, and medical masks. The textile sample is securely clamped to resist constant air pressure during the air permeability test.

The automatic holder simplifies the process of loading the specimen into the test area, making it quick and convenient. Then, simply press down on the holder to initiate testing. Next, the machine’s vacuum pump efficiently draws air through the automatic test head, which features a circular opening, ensuring the test pressure remains consistent. Within seconds, the display will show the air permeability units of the tested specimen or notify you if a nozzle replacement is required. After completing the process, just release the holder and turn off the vacuum pump.

This tester provides precise results for understanding what air permeability is and measuring it across various textiles for quality control and performance evaluation.

Specifications of Air Permeability Tester

| Measurement units | mm/s, m/s, l/m²/s, ft³/min/ft², cfm, cm³/s/cm², l/s/cm², l/m²/min 1/dm²/min ,l/min, m³/min, dm³/s m³/s/m², m³/min/m², m³/h/m², ft³/s/ft² |

| Test mode | Automatic |

| Test head | 20 cm2 (standard) |

| Test pressure | 10~2,500 Pa |

| Air velocity | 0.6~10,000 mm/s(20 cm²) |

| Measurable sample thickness range | 0~10 mm (other thicknesses and fixtures can be customized) |

| Testing Accuracy | <+/-2% |

| Optional test heads | 5 cm²,25 cm²,38 cm²,50 cm²,100 cm² |

Weight of Air Permeability Testing Machine

125kg

Power of Air Permeability Testing Machine

220V/110V 50/60Hz

Dimension of Air Permeability Testing Machine

970*400*970 mm (D*W*H)

Standards of Air Permeability Testing Machine

GB/T 5453 ISO 9237

ISO 9073:15 JIS L1096 Item8.26 Method C

BS 3424-16 BS 6F 100 3.13

NWSP 070.1.RO(15) GB/T 24218.15

Optional Standard of Air Permeability Testing Machine

ASTM D737

Testing principle of fabric permeability

This refers to the vertical flow rate of air per unit area of a fabric at a specified differential pressure, which is the pressure difference between the two sides of the fabric. The measurement is expressed in ‘mm/s’. When a pressure difference exists across the fabric, its ability to allow air to pass through is referred to as air permeability.

Difference between moisture (vapor) permeability test and air permeability test

Vapour permeability refers to the permeability of gases through polymer materials such as films, coatings and fabrics. Vapour permeability refers to the ability of water vapour to pass through a fabric, also known in the industry as ‘moisture permeability’. Only air permeability and vapour permeability are both satisfied in order to obtain a comfortable body feeling. For measuring fabric vapor permeability, use this Auto Water Vapour Permeability Tester TF165B.

Fabric air permeability refers to the performance of air passing through the fabric when there is a pressure difference between the two sides of the fabric.

TESTEX offers good quality air permeability testers for textiles. For more information on air permeability test apparatus, or want to know the air permeability tester price or air permeability test standards, please contact us now! You can also chat with us directly on WhatsApp for a more informal conversation.

You must be logged in to post a review.

Frazier air permeability test method (ASTM D737 testing)of textiles

1.Air permeability definition

What is the permeability of air? The air permeability is the volume of air passing a fabric under pressure. There are two types of air permeability tester for textiles, Frazier air permeability tester and Shirley air permeability tester. In ASTM D737 test method, we take Frazier differential pressure air permeability tester as an example.

2.Test Objectives:

To determine the air permeability of textile fabrics by calculating the air permeability value.

3.Test Materials:

Woven, knitted and non-woven textile materials. eg. cotton.

4.Air Permeability Test Procedure:

4.1 The specimens must be adjusted to the standard atmosphere with 21 +/- 1°C (70 +/- 2°F) and 65 +/- 2 % relative humidity unless there is otherwise specification of contract order.

4.2 Process the specimens carefully and prevent it from changing its' natural state.

4.3 Place each specimen on the test head of the air permeability tester and control the test as the operation manual.

4.4 At the conditioned water pressure, making tests according to the operation manual. In the absence of an operation manual, use a water pressure 125 Pa (12.7mm or 0.5 in. of water).

4.5 Read and record the test results. The air permeability units should be noted. Record the test results respectively in SI units as cm^3/s/cm^2 and in inch-pound units as ft^3/min/ft^2 rounded to three significant digits.

4.6 Take out the tested specimen and continue to test the next specimen until the ten specimens have been tested in accordance with the flow of 4.3-4.5.

4.7 In order to make sure a high accuracy, the number of tests is at least four.

5.Air Permeability Calculation

Calculate air permeability of every specimen by reading directly from the tester in SI units as cm^3/s/cm^2 and in inch-pound units as ft^3/min/ft^2, rounded to three significant digits. Please follow the instructions which the manufacturer provides when calculating air permeability.

Note-If air permeability test results are 600m (2000 ft) above the sea level, it needs correction factors.

6.Report

The data which is needed to report is as follows.

6.1 Report whether the air permeability is in accordance with the Test Method D737.

6.2 Report the standard deviation and the variation factor while calculating.

6.3 The difference in pressure of fabric surfaces.

6.4 Report the model and the manufacturer of the air permeability test equipment.

What important points should be paid attention to when measuring air permeability?

1 Calibration board must be used before each test (all boards should be checked). Mainly air circuit, liquid circuit, air leakage, liquid leakage, position moving will cause an error to the air permeability tester.

2 The sample should be fixed at the intake hole naturally and smoothly. Usually, it does not need to distinguish between positive and negative, but if the positive and negative differences of structures (such as umbrella cloth, filter cloth, pile fabric) are big, air flow direction should be decided according to the actual use.

3 The caliber is selected in order of large to small to avoid the excess of liquid in the pressure gauge. The final selected caliber should be under the indication range of the 15%~85%.

4 Moderate pressure regulation makes the pressure gauge slowly change from low value to constant pressure value. If the liquid level has exceeded the constant pressure value, it must be adjusted back to a lower pressure level and re-adjusted. The pressure has to be stable for a period of time and then can be read.

5 Make sure that the end of the pressure gauge passes through the atmosphere without clogging. Some instruments have covers and should be taken down when measuring.

6 There is a nonlinear relationship between the air permeability and the differential pressure of two sides of the fabric (constant pressure value). The air permeability under differential pressure can be compared according to the following formula:

Q_M=Q_N(∆P_M/∆P_N)^b

The air permeability under the same differential pressure is converted, Q_M and Q_N of which are the air permeability under the constant pressure value of ∆P_M and ∆P_N, and the B is determined by the fabric category and ∆P_N.

7 Different countries have different air permeability unit of measurement. Therefore, please pay more attention to the air permeability units conversion. If you need to convert 1/ dm^2/min to m^3/ m^2/ minor convert l/ dm^2/ min to l/ m^2/ s, here is the air permeability conversion chart as follows for your reference.

Please contact us if you want to know the air permeability tester price or download a free ASTM D737 test for permeability PDF.

[contact-form-7 id="16355" title="Inquiry"]

A: The fabric air permeability is to measure the volumn of air flow through it. The ease or passage of air plays an important role in end uses of many fabrics, such as industrial filters, tents, sailcloths, parachutes, raincoat materials, shirtings, downproof fabrics and airbags.

Air permeability refers to the volume of air per ml which passes the fabric at a speed of 1s or 10s/mm^2 in a pressure difference of 10mm water head.

Q: How to test the air permeability of fabric?

A: In British standard test, the volume of airflow through a specified area is measured at a certain pressure across the fabric with 10mm water head. Test sample is clamped over the inlet of device with rubber gaskets, and air is sucked through it by pumps, which is shown in Fig.A. The air valve is adjusted to exert pressure on air going through fabric of 10mm water head, then a flow meter is used to measure airflow.

Fig(A) : The air permeability test (click here for more)

Q: What is the unit of air permeability of fabric?

A: The formula is as follows:

K (gas) = Q / (ΔP × A)

Where: K( gas) - air permeability, m ^ 3 / m ^ 2 · KPa · h;

Q - gas flow, m ^ 3 / h;

ΔP - gas through the porous material produced by the pressure drop, KPa;

A - area of the sample's test area, m ^ 2

Q: What is air permeability test?

A: Fabric air permeability refers to the ability of a fabric to allow air to pass through it when there is a pressure difference across its surfaces. Specifically, it measures the volume of air that flows through a unit area of the fabric over a specified period under a defined pressure differential. Air permeability test is crucial for determining the breathability and comfort of textiles, especially in applications such as clothing, filtration, and protective gear.

Q: What standards are used for testing air permeability in fabrics?

A: GB/T 5453 ISO 9237

ISO 9073:15 JIS L1096 Item8.26 Method C

BS 3424-16 BS 6F 100 3.13

NWSP 070.1.RO(15) GB/T 24218.15

ASTM D737

Q: What types of fabrics can be tested with an air permeability testing apparatus?

A: Industrial fabrics: such as non-woven fabrics used in technical applications.

Breathable textile products: including fabrics, garments, and other breathable textiles.

Coated fabrics: to evaluate how coatings affect the fabric’s breathability.

Non-woven fabrics: for assessing the breathability of materials like medical textiles and hygiene products.

Highly breathable materials: such as sponges and porous materials.

Paper: for testing its breathability and airflow properties.

Other materials: including leather, plastics, and various chemical products.

Q: What are the comparisons of different air permeability methods(standards)?

A: GB/T 5453-1997: Applicable to various textile fabrics, including apparel fabrics and industrial fabrics.

ISO 9237: Suitable for testing the air permeability of nonwoven materials.

ASTM D737: Differs from GB/T 5453 and ISO 9237 in terms of applicable scope, temperature and humidity conditions, testing area, and pressure differential.

JIS L1096: Widely used in the Japanese textile industry.

Q: What units are used for measuring air permeability?

A: Common Units for Air Permeability:

cm³/cm²/s (cubic centimeters per square centimeter per second)

This unit measures the volume of air (in cm³) that passes through a surface area (in cm²) over time (in seconds). It is commonly used in standards like ASTM D737 and ISO 9237.

L/m²/s (liters per square meter per second)

This unit measures the volume of air (in liters) passing through a square meter of fabric per second. It is widely used in various international standards, such as DIN 53887.

m³/m²/min (cubic meters per square meter per minute)

This unit expresses how much air (in cubic meters) passes through a square meter of fabric over one minute. It is used in many standards like GB/T 5453.

Q: How do I convert air permeability values between different units (e.g., cm³/s/cm² to l/m²/s)?

A: From cm:/cm²/s to L/m²/s

The conversion is straightforward:

1cm3/cm²/s=10L/m²/s

L/m²/s to m*/m²/min

Since 1 liter is 0.001 cubic meters and there are 60 seconds in a minute:

1L/m2/s =0.06 m3/m²/min

From cm:/cm²/s to m:/m²/min

Combining the previous two conversions:

1cm3/cm²/s = 0.6 m3/m²/min

NOTE: The above formula is for reference, please contact us for accurate measurement.

Q: Can I use an air permeability conversion calculator for different fabric types?

A: Yes, you can use an air permeability conversion calculator for different fabric types to easily convert between various units of air permeability (such as cm³/s/cm², l/m²/s, and m³/m²/min).

In our AirFicient, you can select the test standards and measurement units from the operation screen, and then get the result directly without equipping an air permeability conversion calculator.

Q: What factors affect the air permeability rating of a fabric?

A: Fabric Factors:

Fibre Morphology and Yarn Structure:

Shaped fibers (e.g., hollow) have better permeability than round fibers. Thicker single fibers enhance air flow compared to finer ones.

Fabric Organization:

Air permeability ranks from highest to lowest: porous > satin > twill > plain. More open weaves allow for greater air passage.

Fabric Finishing Process:

Treatments like printing and dyeing can reduce permeability by tightening fabric structure. Reduction processes that thin fibers can increase permeability by creating larger gaps.

Environmental Factors:

Temperature:

Increased relative humidity at constant temperature generally decreases air permeability.

Relative Humidity:

Higher ambient temperatures at constant conditions typically increase air permeability.

Air Pressure:

Variations in air pressure on either side of the fabric can non-linearly affect flow rates when temperature and humidity are constant.

Q: How do air permeability ratings vary between different types of textiles (e.g., activewear, outerwear)?

A: Activewear:

3000-10000 L/m²/s; high-performance materials can exceed 15000 L/m²/s.

Outerwear:

500-5000 L/m²/s; waterproof options typically range from 500-2000 L/m²/s.

Casual Wear:

500-4000 L/m²/s; lightweight cotton has higher permeability than thicker fabrics like denim.

Functional Fabrics:

2000-12000 L/m²/s; designed for specific outdoor activities.

Workwear:

300-3000 L/m²/s; focuses on durability but increasingly incorporates breathability.

NOTE: Please refer to the relevant standards for accurate parameters.

Reviews

There are no reviews yet.