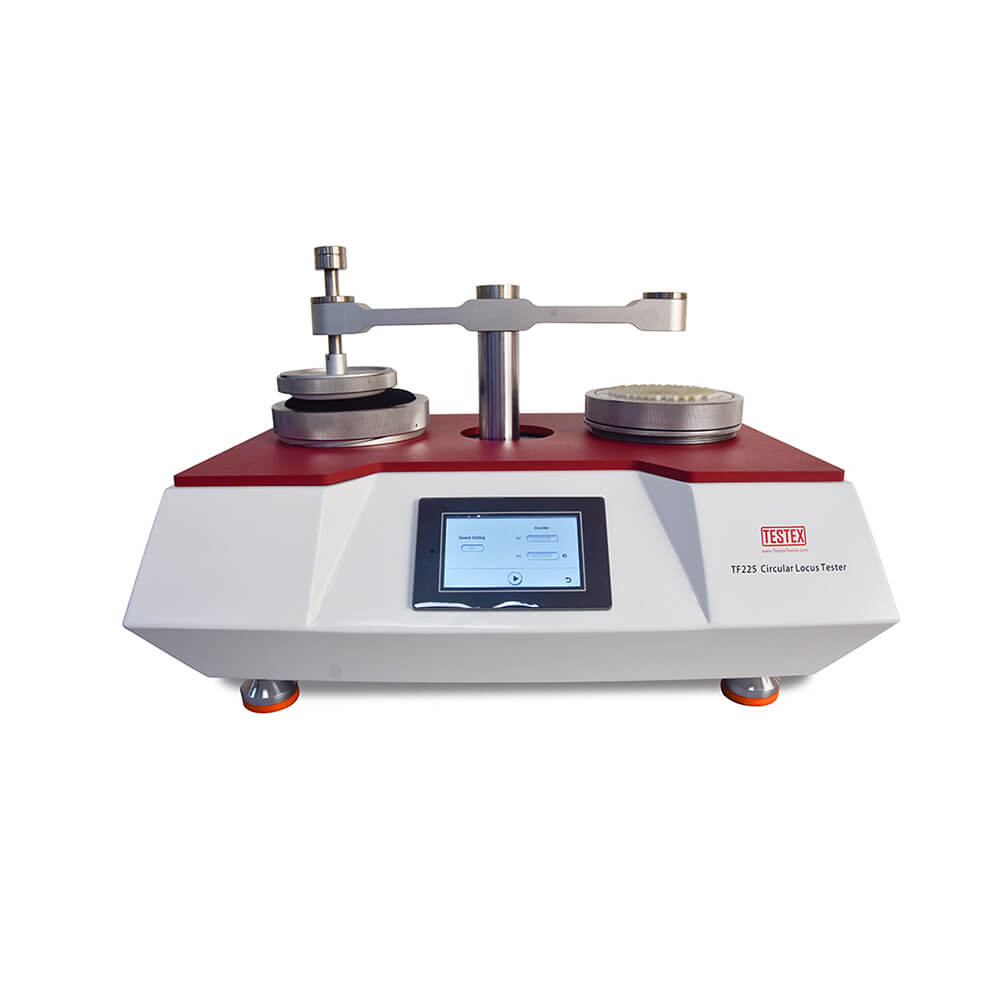

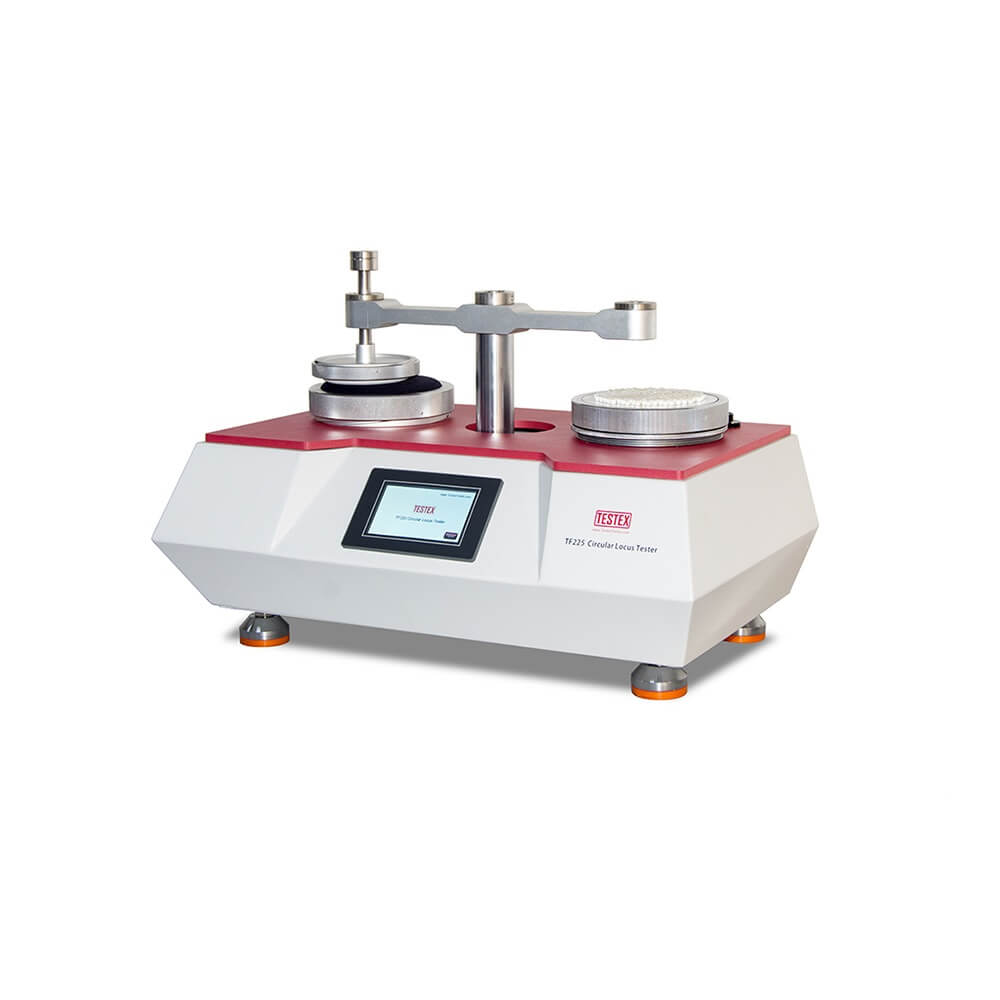

Circular Locus Tester TF225

Circular Locus Tester, to determine surface deterioration and quality of fabrics (wool, chemical fiber, mixed, kitted and woven fabrics). Circular Locus Tester complies with GB/T 4802.1-2008, etc.

Description

Application

Circular Locus Tester, to determine surface deterioration and quality of fabrics (wool, chemical fiber, mixed, kitted and woven fabrics). Using an active friction system, fabric is rubbed against a nylon brush and abrasive or an abrasive only under controlled conditions. Results of the test are achieved in minutes. The relative motion of the locus specimen grip and the abrasive platform is a circle with a relative speed of 60+/-1 r/min. The grip offers pressure to the specimen which is adjustable with a tolerance of +/-1%. For added control and safety, the machine is equipped with a self-stop switch.

Specifications

- Test motion: Circular Locus of Dia. 40mm

- Test speed: 60 ± 1 r/min

- Height of Brush: 2 ~ 12mm, adjustable

- Pressure on specimen: 490cN, 590cN, 780cN,.

- Dimension of specimen: Dia. 113±0.5mm (100cm²)

- Counter: 1 – 9,999 times, stop automatically

Optional orders

- Standard Abradant gabardine

- Standard Backing Foam

- Standard Brush Set

- Woolen fabric sample photos 3 small sets (total 15 photos)

- Knitted fabric pilling sample photo I, II (a total of 12)

Weight

| 30 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 550 mm | Width: 260 mm | Height: 380 mm |

Standards

| GB/T 4802.1 |

8 reviews for Circular Locus Tester TF225

You must be logged in to post a review.

Test Method of Pilling

During the pilling test, there is different test method for different material and use of fabric. For example, both Martindale method and pilling box method are aim at the European market, the random tumbling pilling method is aim at the American market and the circular locus method is aim at the Chinese market.

Brief Introduction of Circular Locus Method

Circular locus method is widely used in China, which is applicable to woven fabrics, part of knitting fabric like sportswear, T-shirt, and underwear. The relevant standard is GB/T4802.1.

For filament fabric and short fiber, the specimen should be abraded with nylon brush at first, then it can be abraded with an abrasive cloth. For wool fabric and fabric easy to pilling, they can be abraded with abrasive cloth directly. After we put down the specimen and compare it with a standard sample in the pilling assessment viewer, we can evaluate its pilling grade.

This method is simple and efficient. But the result of heavy fabric could be affected by the test condition.

The Process of Circular Locus Test

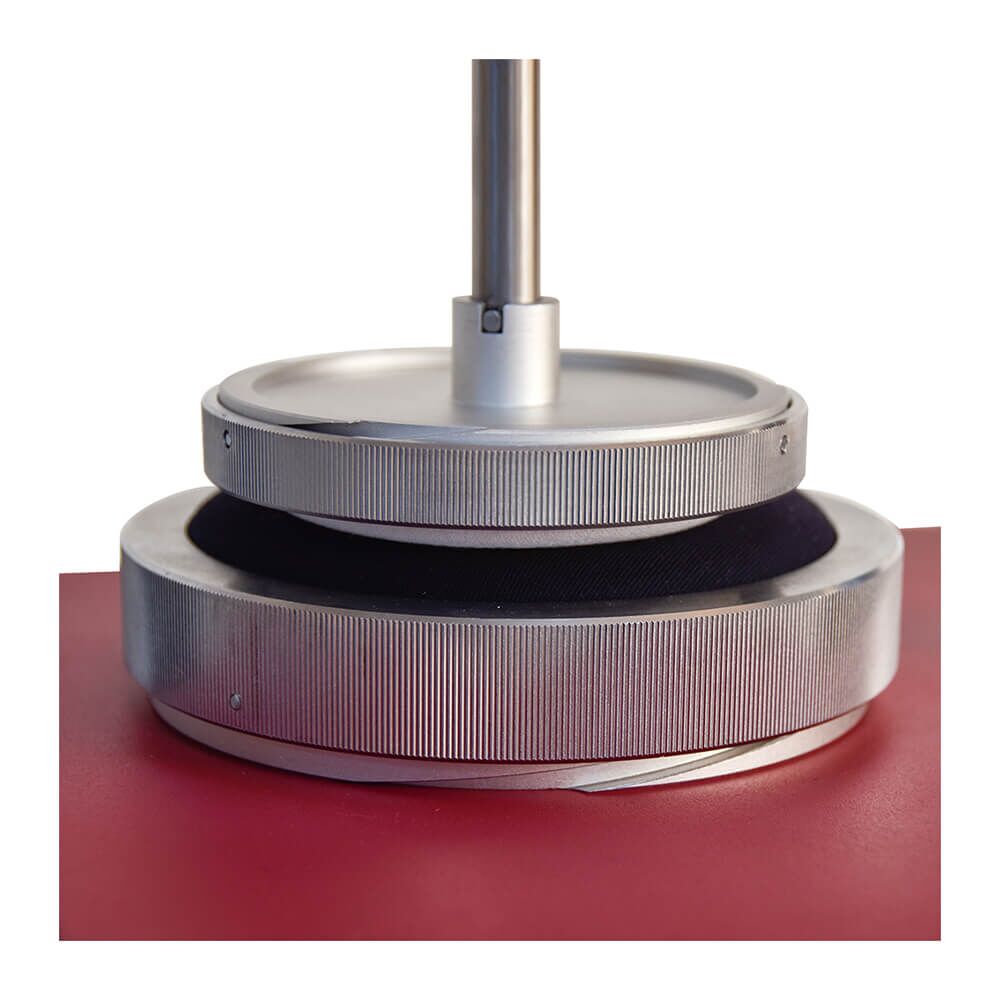

1. Switch the power on, upturn the holder support so that the bottom of the holder is in top position, place a backing foam on the bottom surface of the specimen holder, and place a conditioned specimen on top of the backing foam with its obverse surface outside and secure them tightly by screwing the holder nut.

2. Place a wool felt(if necessary) on top of the pilling table, and place an appropriate Abradant gabardine on the wool felt, and tighten it.

3. Lower the sample holder with the specimen well contacted with the fuzzing brush or Pilling Table.

4. Setting the number of test cycles

5. Press START/STOP key, the machine starts test and stops automatically after the set number of test cycles finished.

6. Press START/STOP key to interrupt running if needed. Press RESET key, the machine starts again and counting from zero. If not to press RESET key and press START/STOP key directly, a counter will count from the current value of finished test cycles.

7. After the whole specimens tested, remove specimens, clean the machine with a soft cloth and cover it to prevent any dust or water.

[contact-form-7 id="16355" title="Inquiry"]

A: Fabric sample pilling with nylon brush at a track of circle motion under a certain pressure, then rubbed relatively with a standard fabric to pilling, or with a fabric abrasive to pilling directly. This test method is suitable for chemical fiber filament fabrics and chemical fiber short fabrics, but if fabrics are used as abrasives, it can apply to fabrics easy to pilling.

Q: According to which standard the TF225 machine is made? GB/T 4802.1-2008 only? Or can make according to ISO 12945 also ?

A: It's based on GB/T 4802.1-2008 only. ISO 12945 is the other standard for Martindale abrasion tester TF210. They are two different test methods responding to two different machines.

Richard Williams –

circular locus tester, just got my standard testing done.

Pitt J –

No trouble to use with the support from the team, proffesional!

Victoria Bartholomew –

Has everything I need, well, nearly everything.

Truda Lytton –

Very satisfied. Arrived on time and is working very well.

Xaviera Joshua –

This is one of the most favourable purchases I’ve made.

Sean Scott –

The delivery can be faster.

testextextile –

We promise that we will arrange it better.

Tom Harte –

great product and customer service.

Merle Nelly –

good reception all details very good, delivery in 7 days very good , very happy. Recommended. thanks