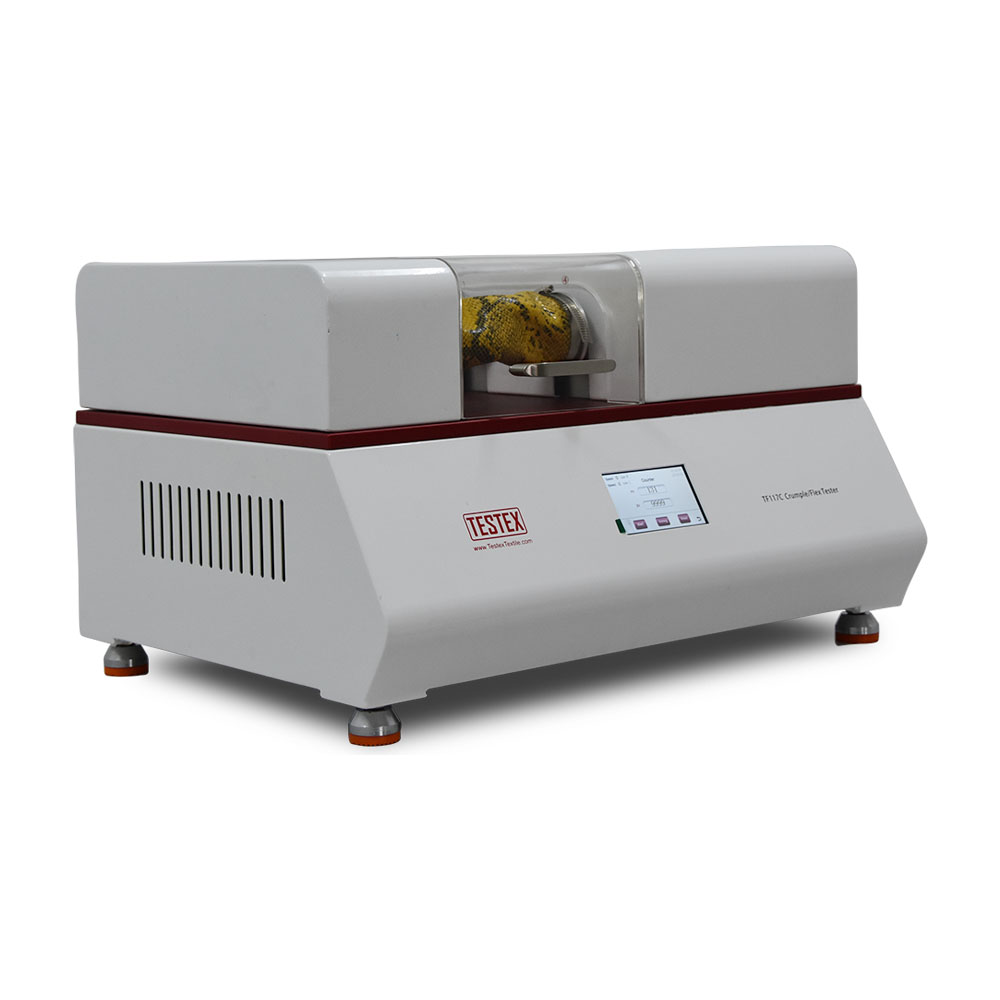

Crumple Flex Tester TF117C

Crumple Flex Tester is widely applicable to determine the degradation of water resistance of coated fabrics due to crumpling and Flexing in use. As we can see, it is necessary to test fabrics in terms of their ability to withstand repeated flexing without creating crackings. One of the machines available and used in such a test is the TESTEX Flex Cracking Tester. Crumple Flex Tester TF117C is a testing instrument with excellent equipment and a stable operation system at a reasonable price.

Description

Crumple Flex Tester, by using this instrument, the users can test the degradation of water resistance of coated textiles due to flexing and crumpling in daily application use, which contributes to improving the water resistance of the fabric performance for the manufacturers.

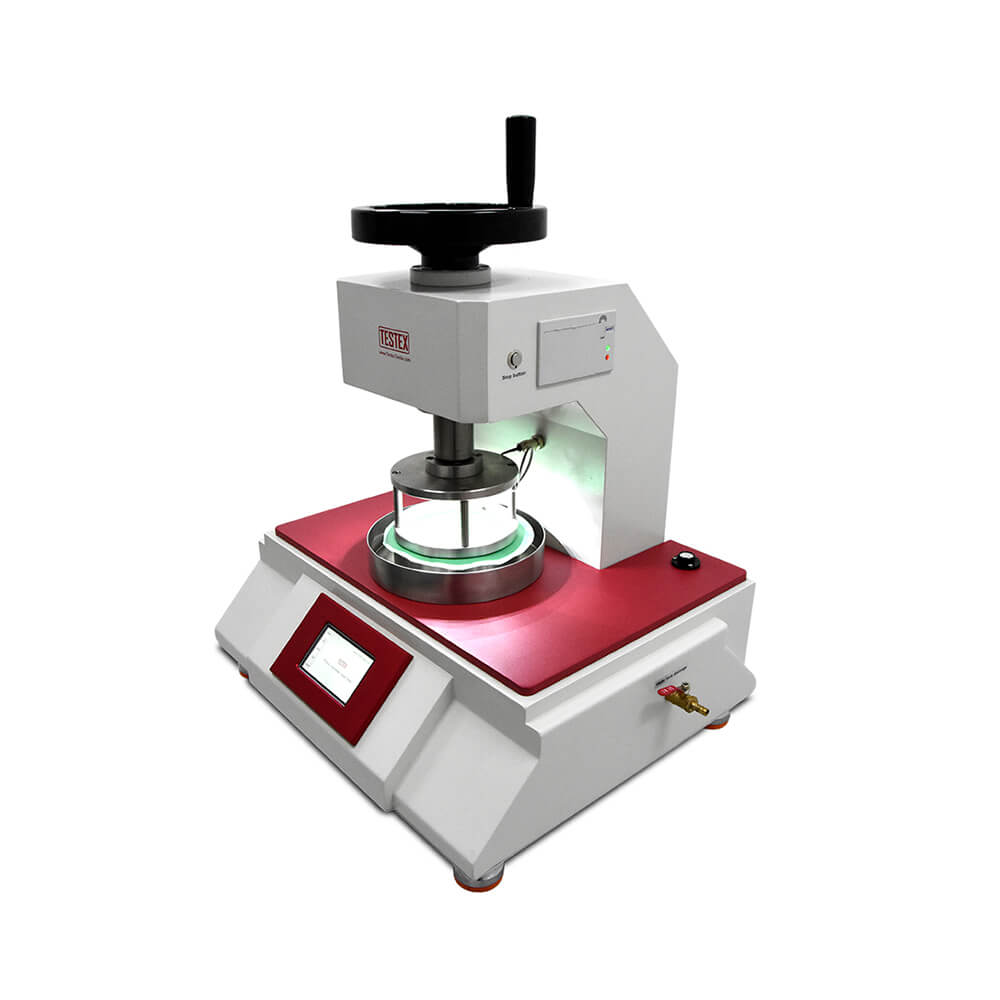

The equipment tests a tube of fabric by twisting it through 90° stretching and alternately compressing the tube at the same time. After the flexure test, immediately, it can test the water penetration resistance of the fabric according to ISO 1420. A pre-set electronic counter automatically stops the crumple flex tester when the test reaches a preset cycle. In all, Crumple Flex Tester measures the waterproof resistance of fabrics by simulating the repeated flexing of a garment during use. Besides, Crumple Flex Tester TF117C is a testing instrument with excellent equipment and a stable operating system at a reasonable price.

Features

- Work stations 2

- Impact design of construction and appearance

- Acrylic safety cover ensures safety in operation

Power

| 220 /110 V | 50/60 Hz | 3 A |

Weight

| 43 Kg |

Dimensions

| Length: 630 mm | Width: 460 mm | Height: 360 mm |

Standards

| ISO 7854 Method C | GB/T 12586 Method C |

Test Principle

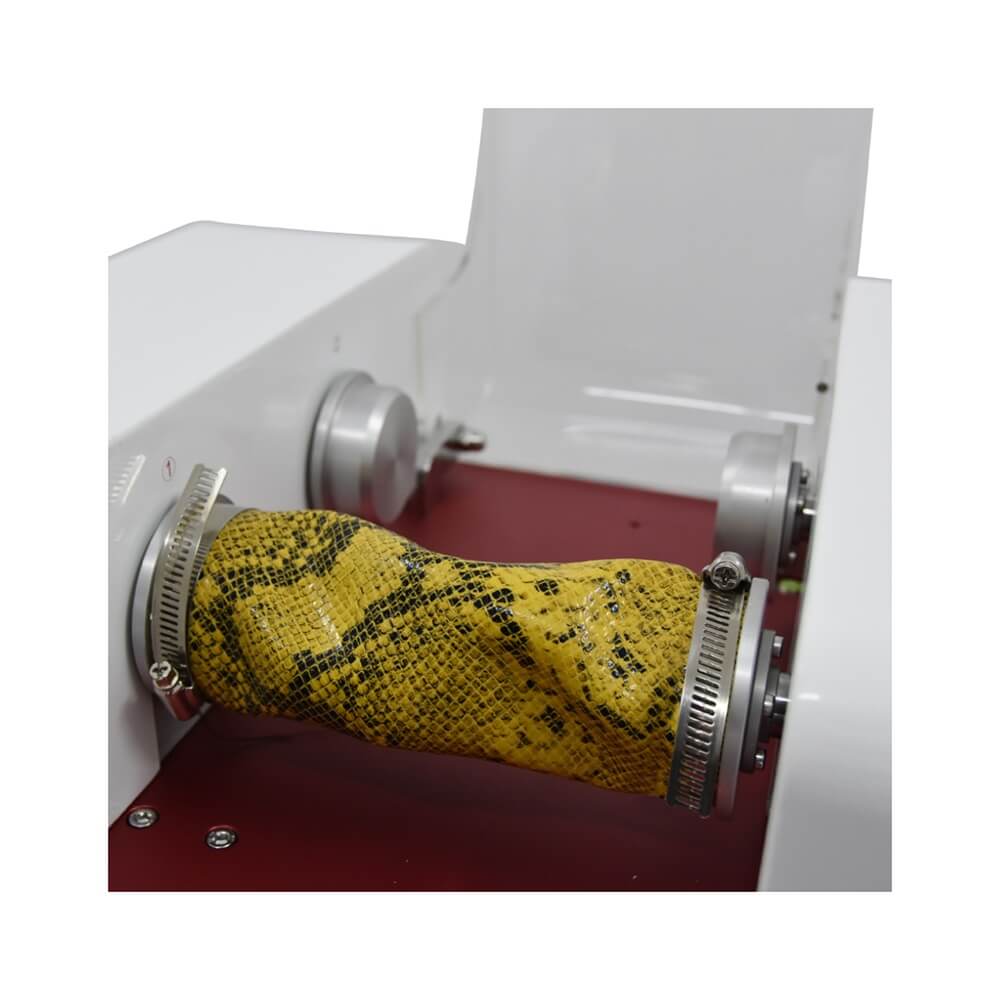

Sew a rectangular piece of coated fabric test sample into a cylindrical shape and mounted it between two discs. One of the discs oscillated approximately 90° on its axis. As a result, the cylinder of the coated fabric test piece will twist. At the same time, the other disc moves reciprocally along its axis, thus causing the cylindrical sample to be compressed along its length. This twisting and compression of the cylindrical test specimen continue for a predetermined number of cycles, or until the test piece appears visibly damaged.

Analysis of flexing damage

Assess the overall appearance, taking into account all visible factors such as wrinkling, cracking, flaking, and discoloration. Compare the flexed test pieces with the unflexed material and grade the flexed material according to the following four scoring levels. For the unbent material, no magnification is required to observe the damage to the appearance.

- 0 None

- 1 Slight

- 2 Moderate

- 3 Severe

Also, if there is flexing damage (cracking and delamination, etc.), please indicate the type and extent of the damage.

Test report

The experiment report should include the following content.

1 Details of the coated fabric markings

2 The number of this standard, i.e. GB\T 12586

3 The situations the instrument works but its operation fails to follow the standard test procedure

4 The specified number of flexures for the test running and for conducting the inspection and the number of flexures for the final inspection

Cracking

We should take a careful examination of the samples by applying a magnifying glass, especially a stereoscopic microscope. If there is cracking, the report should also contain the following regulations, including the cracking depth, the number, and the length.

The grading of crack depth is specified as follows.

No cracking is the best situation.

A- there is cracking on the surface or the finish coat and the foam layer or the intermediate layer is still uncovered.

B- substrate fabric has not been exposed when there is a single coating or the cracking has not penetrated into the middle layer.

C- there is a cracking on the surface of the substrate fabric

D- the cracking covers the whole material.

The number of cracking

The cracking at the lowest level indicates the worst cracking.

Length of cracking

The cracking at the lowest level indicates the worst cracking, which should be expressed in mm.

Welcome to TESTEX – a professional textile testing instrument supplier – Crumple Flex Tester is on sale, contact us to get a detailed price quote.

What is Flexing Resistance

Flexing Resistance is a measure index of bending resistance of rubber, leather, and coated fabric. Take coated fabric as an example, the fabric will be distorted countless times in the process of using and washing, which requires a certain degree of flexing resistance to ensure that the fabric will not be wrinkled or damaged in a certain amount of time. Therefore, folding fastness is an important index of fabric. The fabric is twisted back and forth on a specified test instrument, recording the number of distortions and observing the damage conditions of the coated fabric.

CrumpleFlex Test Method

Principle: stitch a rectangular coated fabric sample into a cylindrical shape, and fix it between two disks. One of the disks wobbles about 90° around its axis and the other moves back and forth along its axis, which distorts and compresses the sample at the same time until the sample has completed a certain number of back-and-forth bending or has obvious damage.

Sample preparation: Cut a piece of sample along the horizontal and longitudinal direction of the fabric. Each sample is 220mm long and 190mm wide, then stitch the sample into a cylinder with 190mm length and 64mm inside diameter, and the coating is outward.

Test procedure: check whether the equipment is running at the required speed before testing, install the cylindrical sample between two disks, each end of the sample is close to the inner side of the disc, and clamp it tightly. The oscillating disc should stop at the center of the pendulum wheel, and the suture line of the specimen should be in line with the midpoint of the oscillating disc when we install the sample. Start the instrument and run it the specified number of times.

Sample inspection: After the test, record the number of flexing, observe the whole appearance of the sample, and evaluate the damage degree of the sample. By comparing the samples with the flexing test and without the flexing test, record the details of wrinkles, fading, and so on of the samples.

The installation

1 Power supply conditions.

Please configure the correct power supply as indicated on the nameplate of the machine. Besides, ensure that the machine should be grounded in the correct way to prevent injury caused by the machine leakage.

2 the requirement of the operating environment: maintain the room temperature

3 the installed position: place the instrument on a horizontal and stable platform to keep the machine stable

The maintenance

1 The surface of the machine should be cleaned before and after each test.

2 The moving part of the machine should be filled with lubricant regularly.

3 The machine should be unplugged when it is not operated for a long time.

If you would like to buy a CrumpleFlex tester or want more information, please contact us.

[contact-form-7 id="16355" title="Inquiry"]