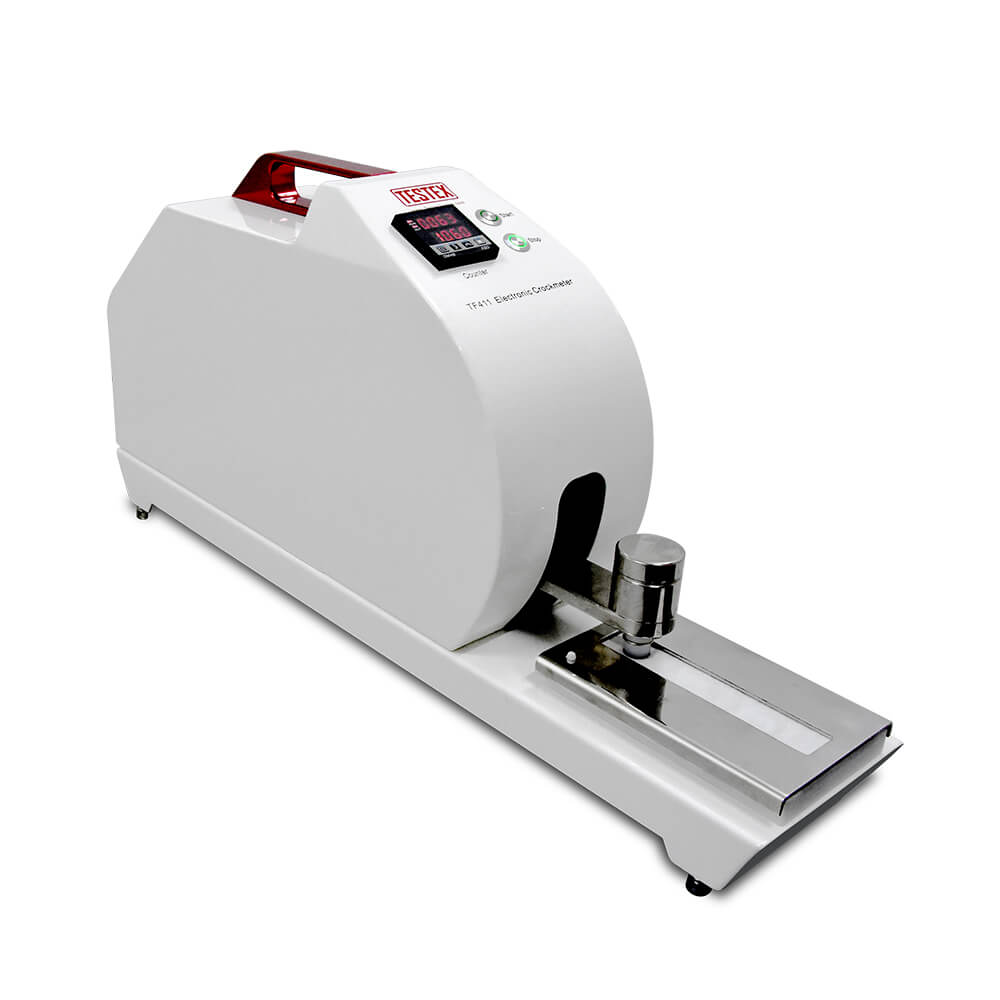

Crockmeter TF411

Crockmeter – The Electronic Crockmeter TF411, is designed to test the color fastness of textiles to dry or wet rubbing, also named a rubbing fastness tester.

The electronic Crockmeter complies with ISO 105×12/D02, AATCC 8/165 testing standards, etc. In the crocking test, a reliable Crockmeter plays a vital role in the repeatable and reproducible results. TESTEX will be your good choice as it has been on the way to improving the Crockmeter with excellent performance and stable operation since its foundation over ten years ago.

Description

Features of Crockmeter TF411

1. Accurate test result

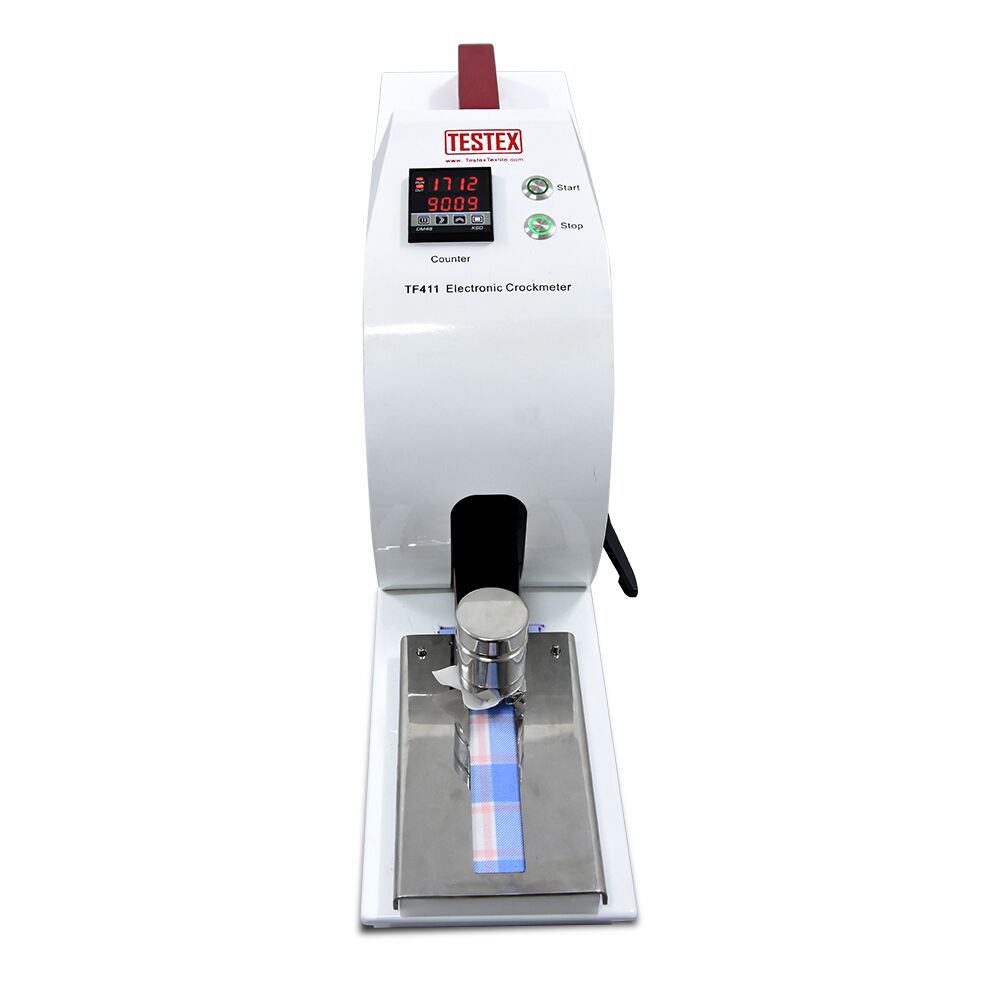

The precision slide rail ensures the linear movement of the friction rod and the friction finger, avoiding the uneven staining test result.

2. Both wet and dry rubbing testing can be performed.

3. Advantageous test sets

An enormous-sized specimen exerts even pressure on the sample,

getting rid of the wrinkles when rubbing.

4. Meet strict standards

Parts such as switches, buttons, and counting meters are from the US

and Japan. They meet strict test standards and have stable performance.

Easy to operate

Easy lift design makes it easy to change either Abradants or Specimens.

The unique Handle design makes this crock meter portable and friendly to female operators.

5. Long Service life

The cover is shielded to prevent dust and other debris from falling into the instrument, prolonging the service life.

6. The load weight can be selected.

Regularly, the reciprocating load arm is weighted to provide a constant 9N load on the sample at all times, and TESTEX can design other weights if you need them.

TF411 is equipped with a mechanical counter that keeps track of completed cycles.

Specifications of Crockmeter TF411

| Type of Crockmeter | TF411 Electronic Crockmeter | |

| Image | ||

| Rubbing head | 16 mm | |

| Vertical pressure | 9N+/-10% | |

| Rubbing stroke | 104 mm | |

| Counter | 1 ~ 999,999 times, automatically stop | |

| Net Weight | 11 kg | |

| Dimensions | 170 mm * 650 mm * 330 mm | |

| Power | 220/110 V 50/60 Hz 3 A | |

| Standards | ISO 105x12(circular rubbing head), GB/T 3920(circular rubbing head), AATCC8 ,ISO 20433 Method C | |

| Optional Standards | ISO 105xD02,ISO 105x12(rectangular rubbing head),GB/T 3920(rectangular rubbing head),AATCC165 |

Accessories

- AATCC rubbing clothing

- Sand paper

- Clamping sleeve

- Sampling plate

Optional Accessories

- AATCC/ISO rubbing cloth

- AATCC/ISO grey card

- Sandpaper

- Rectangular test heads and clamping rings

- Round clamping rings

Test Principle of Crockmeter TF411

The rubbing head (usually weighs 9N) runs with a standard speed in the friction cloth specimen, to do the standard length of reciprocal linear motion, after reaching the set number of times, the Crockmeter automatically stops running. Then use the gray sample card to assess the staining of the friction cloth, so as to assess the rubbing color fastness of the sample.

Application of Crockmeter TF411

The Crockmeter also named rubbing fastness tester, is mainly used in cotton, wool, hemp, silk, knitting, printing, and dyeing industries, the determination of various types of fabric color resistance to dry, wet friction color fastness.

Moreover, the Crockmeter rubbing fastness tester can apply to textiles made from all fibers in the form of yarn or fabric whether they are in the process of dyeing, printing, or coloring. However, it is unwise to use the Crockmeter for carpets or for prints. Because their singling out of areas may be too small to apply this method. Most importantly, we need to carry out the Crockmeter test before or after some treatments, such as washing, dry cleaning, washing, dry cleaning, shrinkage, ironing, finishing, and other processes about textiles. Otherwise, they may affect the degree of color transfer from a material, making it poor.

Besides, the Crockmeter is equipped with an electronic counter with a handle set on the top to take it easy. And it has a piece of sandpaper set under the test sample. Therefore, it is possible to fix the sample during the test, making the rubbing Color Fastness test repeatable. With the aid of a stable slide, the instrument can offer you even and precise testing results.

Except for the rubbing fastness tester, other color fastness equipment including the washing fastness tester, and light fastness tester, can check on this page by clicking here.

The significance of the color fastness resistance

As we can see, it is easy for the color of one piece of cloth to change and transfer to another cloth in the process of manufacturing, wearing, storage, etc., due to the rubbing. What is worst, wearing cloth with poor color fastness, not only will stain other light-colored clothing, affecting the beauty but also surface dyes will be easily transferred to the skin due to the rubbing. As a result, the skin will absorb the dye, causing allergies to the skin, or doing harm to the human body to some extent. Therefore, it is of great importance to test the color fastness resistance and improve it.

Welcome toTESTEX – a professional textile testing instrument supplier – Crockmeter TF411 is on sale, contact us to get a detailed price quote.

12 reviews for Crockmeter TF411

You must be logged in to post a review.

Terminology

Dyeing color fastness: the resistance to transferring the color or stained color to other materials. And the color fading or the transfer may occur during the processing, testing, storage, or usage.

Friction Decolorization: The transfer of color from one material to another material by rubbing.

Test Specification

This method is used to measure the degree of color transfer from colored textile surfaces to other textile surfaces under the effect of friction. It applies to dyed fibers, printed fabrics, or other colored yarns or fabrics. The dry and wet white cotton cloth is used as a friction medium.

Sample Preparation

Crocking Cloth: This is a white unbleached, undyed cotton lawn material

Fabric to be Tested: The sample need not be cut to any specific size as long as an increased portion covers the metallic mounting plate.

Two specimens are required for dry testing and two for wet testing.

The two specimens for each must be such that one is assessed with the long direction parallel to the warp and another parallel to the weft. The wet test must be made with fresh dry samples and crocking cloths which have been wetted with water and squeezed to 100% take up (i.e. 10 grams of fabric is increased to 20 gm's of fabric plus water).

Test Procedure

1 Hang the Loading Piece on the Hang Pin. Mount one piece of crocking cloth onto the Rubbing Finger using the clip provided.

2 Mount the specimen on the base plate. Press the button on the counter to clear the counter to zero. Start the test by shaking the handle clockwise.

3 Take out the white cotton cloth and compare it with the colored grey card or AATCC color card to evaluate the color degree of the white cotton cloth.

Test Principle

Textiles will often rub with other objects when they are used. Sometimes, they are rubbed in wet conditions and even stained with other objects if the dye fails to own good dye fastness. Therefore, there should be some specified requirements for the rubbing color fastness.

The rubbing color fastness refers to the resistance to color fading of fabrics in friction for a long time with each other or other objects to measure its impact on the fabric color fastness.

How to rate the sample?

1 The rating should be accurate to 0.1 level if multiple samples are measured.

2 The white clothes with three layers should be lined under the test cloth when rating.

3 A color transfer ruler or stained gray card should be prepared to evaluate the amount of color transfer to the rubbing cloth of the measurement sample

4 A stained gray card or a 9-step AATCC color transfer card can be used to evaluate the wet and dry rubbing fastness with

How to test the dry and wet friction fastness of fabric?

Dry rubbing

Fix the specimen on the friction head of the friction fastness test machine, so that the warp direction of the rubbing cloth is the same as the running direction of the friction head. In the length direction of the dry rubbing specimen, the machine is switched on with a reciprocating dynamic range of 100 mm and a vertical pressure of 9 N on the friction head, respectively detecting the longitudinal and latitudinal direction of the specimen. Specimen and friction cloth in the standard atmosphere to adjust the wet, the test should be carried out in the standard atmosphere.

Wet friction

Wet friction specimens must be wetted with tertiary water, removed, and placed on a dripping net to drip evenly, or squeezed using a liquid roller to achieve a water content of 95% to 105%. Other operations are essentially the same as dry friction testing. After the wet rubbing test, the wet rubbing cloth is left to dry at room temperature.

Report Content

Indicate whether dry or wet friction and write out the evaluation results. Write down whether to use a stained gray card or a colored card in the rating process and describe the treatment of the sample.

Caution

1 The colour fastness to rubbing test should be carried out on the front side of the specimen. If any dyed fibres are brought out and left on the rubbing cloth, they must be removed with a brush.

2 The lining fabric should be stored in a sealed, light-proof, and dry place to avoid contamination, moisture, and yellowing.

3 Before testing, the rubbing surface of the friction head should be carefully checked to ensure that it is smooth and uneven.

4 The rubbing fabric should not be loosened when fixed to the friction head. After fixing, the rubbing head should be carefully placed on the specimen to avoid accidentally increasing the degree of staining.

If you want to know more, please contact us. As a professional supplier of textile instruments, we are committed to continually improving the user experience. TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

A: TF411 Crockmeter is electronic mode, and TF410 Crockmeter is manual mode. The Electronic Crockmeter is more labor-saving to use and easy to use. If you want for fewer times rubbing fastness tests, you could choose Manual AATCC Crockmeter.

Related products

-

Perspiration Tester / Perspirometer TF416A

Rated 4.86 out of 5 -

Scorch Tester (Sublimation Fastness Tester) TF415D

Rated 4.50 out of 5 -

Gas Fume Chamber TF417

Rated 4.71 out of 5 -

Water-cooled Light Fastness Tester TF422

Rated 4.67 out of 5

jeff green –

this crock meter just did it word done perfectly, stable and efficient

tony young –

best crockmeter in the market, nice service

Daniel Norman –

Best crockmeter in the market perhaps, very elegant design and intuitive to use.

Odelette Bird –

Works as we expected. Really quick delivery too.

hüseyin aytaş –

How can we test according to BS 4655 in this equipment?

Gill Nicholas –

Arrived on time. Crockmeter is easy to use, accurate, and seems to be of good quality.

Zachary Felton –

Great crockmeter with favourable price!

Devin Hemingway –

The Crockmeter has good performance and the price is reasonable.I recommend it to you all.

Albert Larkin –

Good suppiler of crockmeter!

Jamie Baker –

The aatcc crockmeter is so cute, so does its performance and the manufacturer. Recommend A+++++++

Tyrone Charles –

excellent, faster, machine excellent.

Edward Malan –

OK