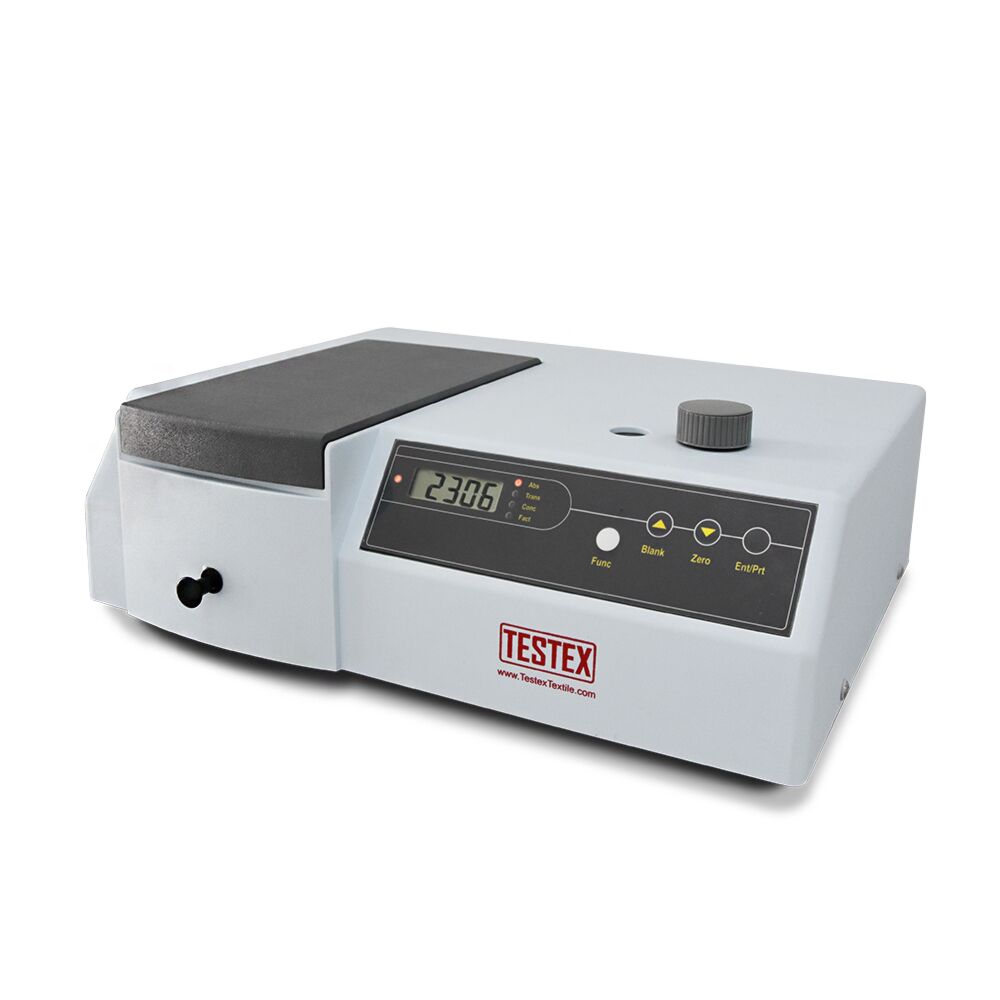

Formaldehyde Content Tester TF136

Formaldehyde Content Tester, used for rapid determination of formaldehyde content of variable textiles. To simultaneously measure formaldehyde value and absorbance value by using the extraction method.

Description

Formaldehyde Content Tester, used for rapid determination of formaldehyde content of variable textiles. To simultaneously measure formaldehyde value and absorbance value by using the extraction method.

Features

- Microprocessor control and automatic data processing spectrum.

- Most test methods can be done on this machine, such as absorption curve, wavelength, absorbance and transmittance, etc.

- With computer online operation, more curve tests can be conducted.

Specifications

Measuring range of transmission ratio: 0.0%T-125.0%T

Measuring range of absorbance: -0.301A-1.999A

Wavelength Range 330-1000nm

Wavelength Accuracy ±2nm

Wavelength Repeatability 1nm

Light Source Imported tungsten halogen lamp

Microcomputer control with LCD display.

the online operation, capable of standard curves and data processing, such as data storage, statistical analysis, calculation printing, etc.

Power

| 220 V | 50 Hz |

Weight

| 10Kg |

Dimensions

| 460 x380 x170 mm (L x W x H) |

Standards

| ISO 14184.1 | ISO 14184.2 | AATCC 112 | GB/T 2912.1 |

| GB/T 2912.2 | |||

2 reviews for Formaldehyde Content Tester TF136

You must be logged in to post a review.

The Function of Formaldehyde Content Tester

Formaldehyde detector is a fast measuring instrument for formaldehyde content in the indoor air. The formaldehyde tester is simple in structure, small in size, easy to carry and easy to operate. The instrument is widely used in indoor, public places and factories and mines in the air of the detection of formaldehyde.

Testing Principle of Formaldehyde Content Tester

The formaldehyde content instrument adopts high electrochemical sensor principle, combined with single-chip microcomputer technology to collect air samples in the testing place, the formaldehyde in the air is absorbed by the phenol reagent solution, and develops color, then read the color change by a photometer.

The Main Features

1 Using the extraction method, measured values of formaldehyde, absorbance values, and transmittance values can be measured at the same time.

2 MCU control, automatic processing of spectral data, Chinese and English liquid crystal display.

3 The use of electrochemical sensor principle, combined with single-chip technology for continuous collection of absorbance values of different concentrations, the microcontroller automatically calculate the curve formula for the corresponding absorbance values of different concentrations.

4 The instrument is mainly imported long-life tungsten halogen lamp, light wave band adjusting device, self-aligned light path module design with selected wavelength and wide range of test wavelengths selected.

5 The host can do more than 7 sample standard absorption curve functions; curve calculation using discrete calculation methods, direct display a, b value (standard curve y = a + bx), without manual calculation.

6 Online data transfer with computer, print data report.

Test Operation

1 Check before starting

The power supply used by the instrument must be grounded to ensure safety. Check if the instrument band is adjusted to the formaldehyde test band.

2 Check after opening machine

Turn on the host power, check whether the LCD screen is normal, otherwise, check whether the circuit is loose. Press any key to enter the working interface, otherwise check if the line is loose. The instrument must be warmed up for 30 minutes before it can be operated experimentally.

3 Reagent preparation

Make the Nessler reagent and stored in a brown bottle. Make the reagent blank and sample blank as required, and cool them in a dark place for 30 minutes, ready for a test.

4 Test step

After power on, press any key to enter the main work interface. Press the [Set] button to enter the setting interface. Set the method, parameter and curve settings. Start testing the sample and wait for the data to stabilize.

Equipment Maintenance

1 Always keep equipment and control systems clean and hygienic.

2 Prevent high temperatures, excessive humidity, dust, corrosive media, water, etc. from immersing inside the machine or control system.

3 Regular inspections to maintain the integrity of parts and components.

4 Do a good job of checking the instrument regularly to ensure the accuracy of the measured values of the instrument

5 The pressure indication has been calibrated prior to shipment from the factory. Non-professional maintenance personnel shall not arbitrarily calibrate. Otherwise, the pressure of the instrument will not be accurate.

6 Non-professional maintenance and inspection personnel shall not dismantle the instrument. After each dismantling, the measurement performance must be verified so as to avoid instrument misalignment.

[contact-form-7 id="16355" title="Inquiry"]

Related products

-

Formaldehyde Emission Climatic Test Chamber TU350

Rated 4.75 out of 5

Frederic Hume –

Formaldehyde Content Tester works great, however the delivery time is a little long.

Yves Melville –

Great Machine.We haven’t experienced any major issues with it.