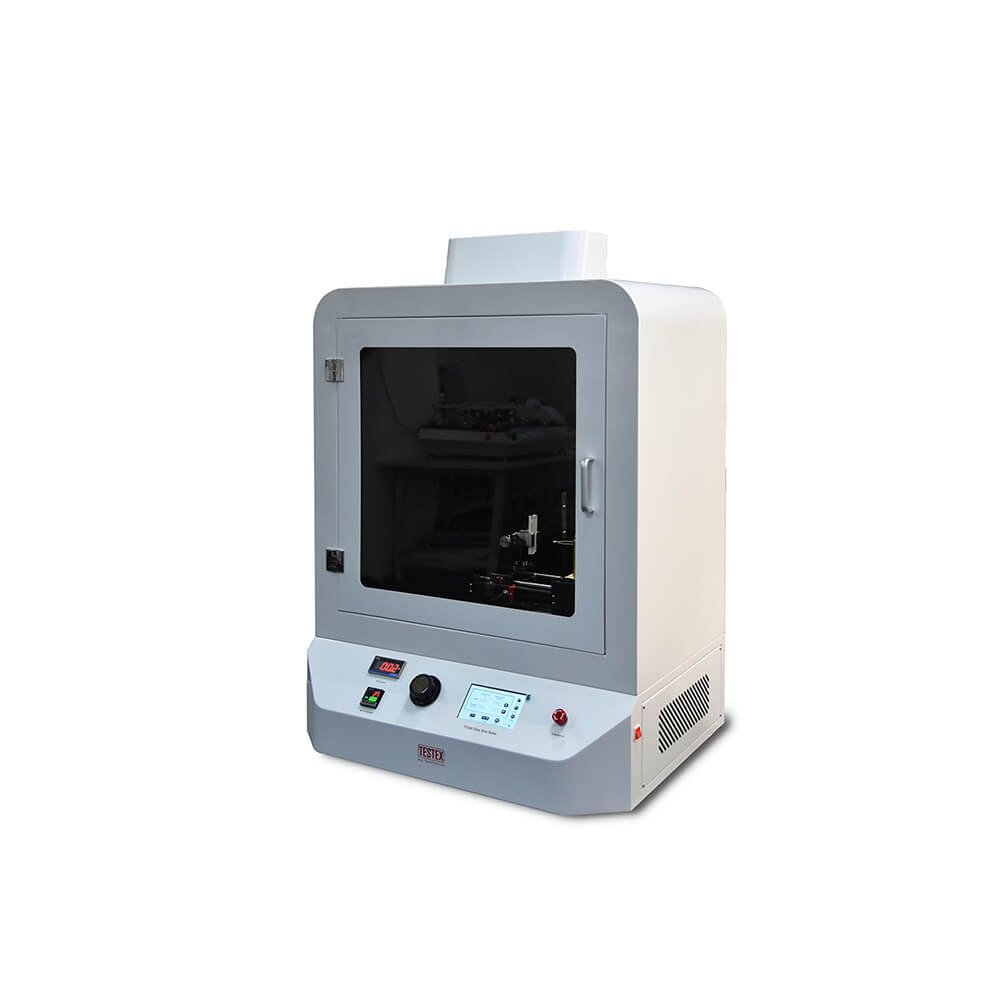

Glow Wire Tester TF346

Glow Wire Tester is used to simulate the thermal stress generated by heat sources such as heating elements or overload resistors or ignition sources over a short period of time, to determine the fire hazard of electrical parts and components. This Glow Wire Test Equipment standards conform to IEC 60695-2-10, ASTM D6194, GB/T 5169.10-13.

Widely used for testing electrical and electronic products like lighting equipment, low-voltage apparatus, and electrotechnical instrument. As a leading manufacturer, we offer a competitive glow wire test apparatus price.

Description

Application

Glow Wire Tester to determine the fire hazard of electrical parts and components. For example, overload, short circuits, poor connections, or others that could ignite and spread the flame to the other part. This instrument is suitable for testing plastic and non-metallic insulating material parts for electrical and electronic products, components, and household electrical appliance parts, e.g. switch housings, relay sockets, etc.

TESTEX Glow Wire Tester, using the indirect method. (Known as the IEC method, compared to the direct method defined in UL94 method). This device applies heat to the specimen over a period of time, simulating an overloaded resistor or other ignition sources, to reproduce as closely as possible what actually occurs.

In addition, we have other flammability test equipments that cater to different test ranges and requirements, they comply with complies with ASTM D1230, FTMS191-5908, BS EN71-2:2006, ISO 15025, FMVSS 302, ASTM D6413, UL HB, etc.

Test principle

The glow wire test apparatus simulates the possibility of ignition of insulating materials inside the equipment that is susceptible to flame spread due to the hot wire. Under certain conditions, such as fault currents flowing through the conductor, overloading of components, and poor contact, certain components can reach a certain temperature and cause the nearby parts to ignite.

Specifications

- Glow Wire Ø 4mm ± 0.04mm Ni/Cr (80/20), standard

- Temperature Range: indoor temperature ~ 960°C, adjustable

- Sample pressure: 1N ± 0.2 N

- Test speed: 18 ± 3 mm/s

- Test mode automatic control, independent convulsions

- Chamber ≥0.5m³

- Control single chip microcomputer + touch screen control

Features

- Equipped with an automatic control system. After start-up, the trolley loaded with specimens will automatically run to the scorching wire and then will return automatically after reaching the set scorching time, making it easy to operate.

- The unit has an illuminated unit with a digital display of time and temperature, a large viewing window, and black walls, so it is easy to observe and record.

- The temperature controller with the thermocouple provided allows for accurate measurement of the glow tablet temperature.

- The fully automatic instrument has a control unit circuit fully protected by fuses and a miniature circuit breaker, and also with a large box on the outside for maximum operator safety.

Weight

| 123 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 1130 mm | Width: 570 mm | Height: 1200 mm |

Standards

| IEC 60695-2-10 | ASTM D6194 | GB/T 5169.10~13 |

The Distinction among GWIT, GWFI, GWT

GWT consists of three tests from IEC 60335 (GWIT, GWFI, and GWT), which are slightly similar but not the same, and can distinguish as follows.

-

GWFI: Glow-wire flammability index

The GWFI is a test of the ignition temperature. If the flame of the sample is extinguished within 30 seconds after the removal of the glow wire, the sample is not ignited by the packaging paper under the sample, and the sample does not ignite, then this temperature can record as a pass.

-

GWT: Glow Wire Test

The GWT and GWFI tests are similar because they both use the above conditions to determine if the test is passed after a specific temperature has been selected.

-

GWIT: Glow-wire Ignitiontemperature

GWIT is the minimum temperature at which the material ignites and burns for more than 5s when the heating element comes into contact with the sample. (Ignition is judged to be flaming for ≥ 5 seconds).

Welcome to TESTEX – a professional textile testing instrument supplier – Glow Wire Tester TF346 is on sale, contact us to get a detailed price quote.

2 reviews for Glow Wire Tester TF346

You must be logged in to post a review.

IEC 60695-2-10: glow wire test apparatus and common test procedure (glow wire test method)

Glow Wire Tester Definition

The glow wire tester is designed and manufactured according to the requirements of the "glow wire test method" in IEC60695-2-10, GB/T5169.10, and ASTM D6194 standards to simulate the thermal stress caused by the heat source or ignition source such as a heating element or overload resistance in a short period of time.

The glow wire test for plastics is to determine the resistance to fire-insulating parts. And the glow wire test simulates the situation of what the plastic material will happen when contact with an over-heated part.

Test Specification

The glow wire tester is suitable for the ignition test of electrical and electronic products such as lighting equipment, electric appliances, household appliances, machine tools, electric motors, electric tools, electronic instruments, information technology equipment, electrical connectors, etc., as well as suitable for insulation materials, engineering plastics or other solid combustible material industries.

Working Principle of Glow Wire Tester

After heating the nickel chromium wire (U-shaped glow wire head) with a high current to the specified test temperature, blanch the sample at a specified pressure for 30s. The ignition risk of electrical and electronic equipment is determined according to whether the test material and bedding burn or not and whether it burned. Record the burning time, ignition time, flame extinguishing time, and flammability index after the completion of the test.

Glow Wire Test Procedure

The glow wire temperature should be set up first. Heating the glow wire to reach the required temperature.

Move the glow wire to contact with the specimen.

Record the result accord to the glow wire test standard.

Please feel free to contact us if you want to know the glow wire test apparatus price.

Precaution and Maintenance

- It is recommended to use a regulated power supply, otherwise, the temperature will change due to excessive voltage fluctuations.

- The scorching wire should not work at high temperatures for long periods of time to avoid shortening the service life of the thermocouple. The current should be reduced in time after each use or the power supply should be disconnected.

- After the test, the combustion chamber should be cleaned with the power off and care should be taken not to collide with the thermocouple and the scorching wire.

- After the test has been completed the exhaust fan can be used to discharge the exhaust gases produced during combustion, but do not turn on the fan during the test as this may affect the test results.

- If repairs are required, especially the replacement of the scorching wire, care should be taken to retighten the screws that have been set, otherwise, the current circuit will be affected by poor contact and high temperatures will be generated at the interface. The user should tighten all screws after replacing parts.

- The machine has an over-temperature protection function which automatically disconnects the heating circuit when the set temperature is reached. Therefore, the preset temperature must not be lower than the normal working temperature, otherwise, it will not work properly.

[contact-form-7 id="16355" title="Inquiry"]

A: The glow wire is one of the parts of the Glow Wire Tester. During the test, the glow wire is used to be preheated to a required temperature.

Q: Do you have some document about the standards?

A: We can offer IEC 60695-2-10 PDF and glow wire test UL746A PDF. Please contact us by email.

Kerwin Van –

Works great and very ease to use.

Randolph Fanny –

The Glow wire tester price is reasonable.