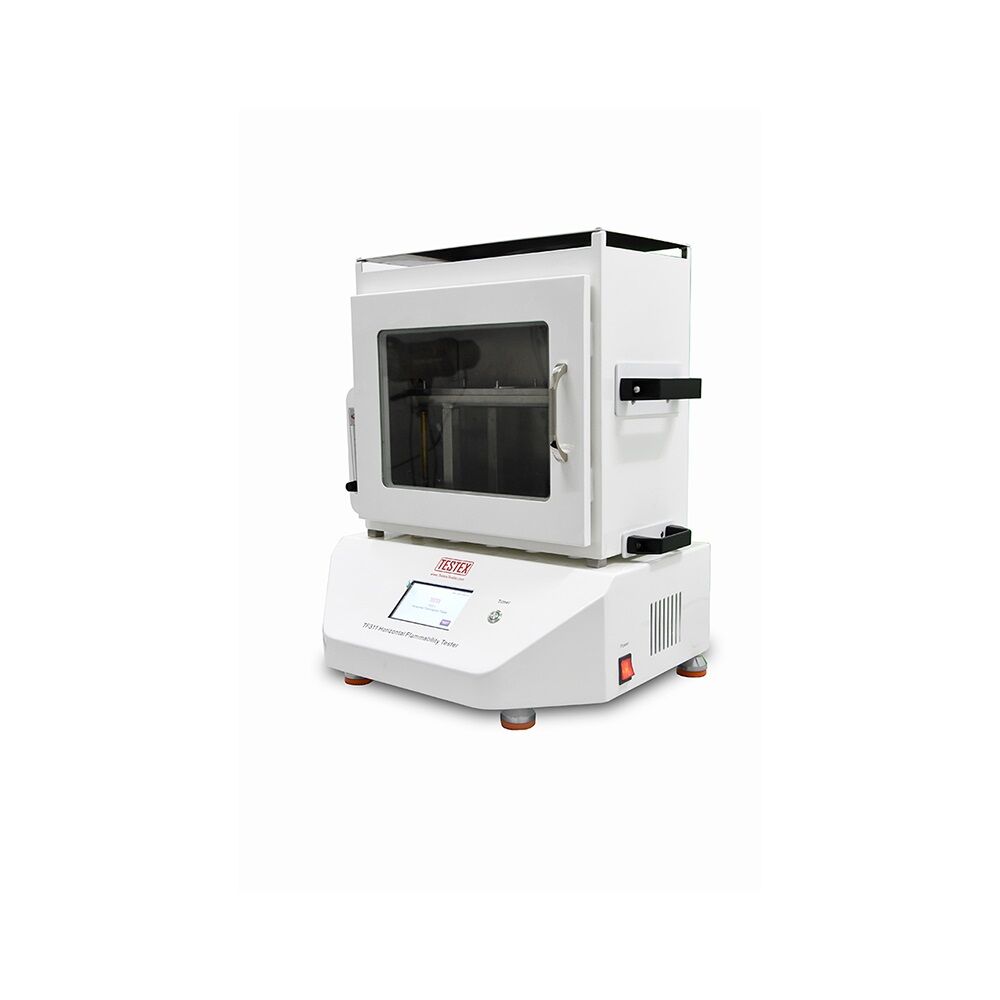

Horizontal Flammability Tester TF311

The horizontal Flammability Tester is called the horizontal method of flame retardant performance tester, used for all kinds of textile fabrics horizontal direction burning performance determination, and the flame spread rate to express. Used for simulation technology to assess the risk of fire, and the product’s surrounding fire to ensure that it does not cause the spread of combustion. Horizontal Flammability Tester complies with ISO 3795, ISO 17074, DIN 75200, etc.

This Flammability Tester has a small size, so it can be placed on the desktop, you can do the flame test with many kinds of flammability test standards. The flammability testing method is simple you can master it quickly. This flammability test equipment also has an ultra-large observation window, you can more clearly see the fabric burning situation.

Description

Application of Horizontal Flammability Tester TF311

The Horizontal Flammability Tester is suitable for testing the flame retardant properties of leather interior materials, polymer materials, textiles, etc. Such as used in all kinds of automobiles, including seat cushions, seat belts, roof linings, armrests, decorative panels, headrests, floor coverings, sun visors, curtains, and other interior parts. Thus, it provides the data basis for new material research and development, product quality acceptance, etc.

In addition to TF311, we also have a series of other flammability testers that you can click to learn more about.

Features of Horizontal Flammability Tester TF311

Safety settings: the flammability tester box shell is a steel structure and encloses the testing process. Through the transparent observation window, you can clearly observe the whole combustion process.

Accurate: the test data is consistent with internationally renowned third-party laboratories.

Very simple operation: gas and fire buttons, an LCD program, real-time display of ignition time and combustion time.

The high degree of automation: automatic recording of test time, automatic display of results and automatic timing once the test starts.

Reasonable design: Equipment with its own fan, test combustion fumes safely discharged.

The flammability testing machine is beautiful in appearance, easy to use, and reliable in performance.

Specifications of Horizontal Flammability Tester TF311

- Fire nozzle DIA: 9.5mm

- Fire height 38mm+/-2

- Sample clamp 360 x 100mm / Interior dimension 330x50mm

- The sample below 25mm pitch between metal wire is 25mm

- Marked line Starting point 38mm / Endpoint 292mm from the Ignition point

- Nozzle to Sample 19mm

Standard Accessories of Horizontal Flammability Tester TF311

- Metal combs

- Punch

- Sampling plate

- Bunsen burner (φ9.5mm)

Weight

| 46 kg |

Power

| 220/110 V | 50/60 Hz | 3 A |

Dimensions

| Length: 485 mm | Width: 360 mm | Height: 570 mm |

Standards

| ISO 3795 | GB/T 8410 | DIN 75200 | ISO 17074 |

| ECE R118 Appendix 6 |

Optional Standards

| FMVSS 302 (Ф 10mm Flame nozzle) |

Why Choose TESTEX Horizontal Flammability Tester TF311

Strictly meet standards

All data for TF311 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples, the same machine, after multiple tests, the results are consistent.

High reproducibility

With the same set of samples, and different machines of the same model, after multiple tests, the results are consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Horizontal Flammability Tester TF311. So feel free to contact our service team with any questions you may have.

Precautions for Operating the Horizontal Flammability Tester TF311

- Place the test equipment in a well-ventilated environment to avoid the toxic fumes generated during the test to affect the health of the operator.

- During the test, this equipment should be grounded to avoid electrostatic reactions.

- When connecting the air source, attention should be paid to the air pipe for air leakage.

- After the test, clear the combustion residue in time to keep the equipment clean.

- Spray anti-rust oil on the surface of this equipment regularly to prevent rust and corrosion after a long time.

- Regularly inject lubricant into the transmission parts of this equipment to ensure that each test can be carried out smoothly.

Welcome to TESTEX – a professional textile testing instrument supplier – Horizontal Flammability Tester is on sale, contact us to get a detailed price quote.

9 reviews for Horizontal Flammability Tester TF311

You must be logged in to post a review.

Test Principle

A sample is held horizontally in a U-shaped holder and is exposed to the action of a defined low-energy flame for 15s in a combustion chamber, the flame acting on the free end of the sample. The test determines if and when the flame extinguishes the time in which the flame passes a measured distance.

Sample Preparation

Take 5 samples from the tested items. If the object burns at a different speed in different directions, the sample should be intercepted and tested separately in different directions. The method of sample interception is as follows.

1 When the article is intercepted by width, the sample should be intercepted containing the full width and at least 500mm length, and the material from the edge of the 100mm shall be cut off, then intercept the samples equidistant and evenly in the rest article.

2 If the shape and size of the article meet the sample requirement, intercept the sample normally from the article.

3 If the shape and size of the article do not meet the requirements, the test must be carried out according to this standard. The test samples (356mm*100mm) should be made with the same material and process like the same structure of the article, and the thickness of which should not exceed 13mm. This test result cannot be used for identification, certification, etc., and it must be indicated in the test report.

4 If the thickness of the article is more than 13mm, the thickness of the sample including the exposed surface is 13mm by mechanical cutting from the non-exposed surface.

5 If the thickness of the article is not uniform, make the thickness of the article uniform to the minimum thickness by mechanical cutting from the non-exposed surface.

6 If the bend of the article fails to intercept the flat specimen, the flat part of the article should be taken as far as possible, and the arch height of the specimen shall not exceed 13mm; If the arch height is more than 13mm, the test samples (356mm*100mm) should be made by the same material and processes like the same structure of the article, and the thickness of which should not exceed 13mm.

Test Step

1 The sample should be adjusted, for at least 24 hours, but not more than 168 hours, under the standard environment of 23±2 ℃ and 45%~55% relative humidity before the experiment.

2 Place the sample in the sample holder so that the exposed side will downwards to the flame.

3 Adjust the gas flame to a height of 38 mm using the mark in the chamber, the air intake of the burner being closed. Before starting the first test, the flame shall burn for at least 1 min for stabilization.

4 Push the sample holder into the combustion chamber so that the end of the sample is exposed to the flame, and after 15s cut off the gas flow.

5 The measurement of the burning time starts at the moment when the foot of the flame passes the first measuring point. Observe the flame propagation on the side burning faster than the other (upper or lower side).

6 Measurement of burning time is completed when the flame has come to the last measuring point or when the flame extinguishes before coming to the last measuring point. If the flame does not reach the last measuring point, measure the burnt distance up to the point where the flame is extinguished.

7 Insofar as the sample does not ignite or does not continue burning after the burner has been extinguished, or when the flame extinguishes before reaching the first measuring point so that no burning time is measured.

Test Result

1 Expose the sample to a flame for 15s, if the specimen does not burn after extinguishing the source of the fire, or the sample can burn, but the flame is extinguished before reaching the first measuring line, there has no combustion distance can be counted, so the combustion rate requirement is considered to be satisfied, and the result is recorded as A-0mm/min.

2 If the flame is extinguished within 60 seconds since starting the test timing and the combustion distance is not more than 50mm, it is also considered to satisfy the requirement of combustion rate, and the result is recorded as B.

3 If the flame is extinguished between two measuring standard lines since starting the test timing and does not meet the requirements of 2 above, the combustion rate should be calculated, and the result is recorded as C- combustion rate.

4 The flame burns to the second standard line since starting the test timing, record the actual burning time if the burning time is less than 20min, and record the burning time as 20min if the burning time exceeds 20min, then calculate the burning rate. The result is recorded as a D-combustion rate.

5 If the sample has been burned to the first standard line within 15s of flame ignition, it is considered that the sample cannot meet the requirements of combustion rate, and the result is recorded as E.

[contact-form-7 id="16355" title="Inquiry"]

A: The two measures the flammability of fabrics, but they test in different directions: one is horizontal test; the other is vertical test. In addition, you can choose them according to their standards, as they meet with different standards.

Q: Is TF311 Horizontal Flammability Tester safe for the use of fuel gas?

A: Yes, of course safe. As the used amount is little, it will be no problem that you close it when test is finished. Therefore, please make sure whether you close the machine after testing.

Q:How to deal with the waste gas? Does the chamber require a pipe/chimney to let the waste gas out?

A: Regarding the waste gas, don’t worry. This test emits a little amount of waste gas, so you just open the door to discharge. You can buy a fume hood if you still worry.

Daniel –

Automated tests, gas and fire buttons, an LCD program, real-time display of ignition time and combustion time.

Cook –

The instrument is very easy and safe to use and it tests the fire resistance of fabrics.

Thomas –

For horizontal fire hazards test, this instrument is good, elegant design.

Verna Elinor –

I recommend the best Flammability Tester suppiler to you all

Gill Wilde –

Good tester, though with some problems. However, the seller is active in solving problems for me.

testextextile –

Thanks for your satisfying with our services!

Ward Wallace –

Good price, good textile tester!

Joanna Nelly –

As the horizontal flammability tester price is reasonable, with nice manufacturer, I will come back to buy again.

Joy Grote –

The machine was very easily operated, well appearence, and from quality material! This is a great seller who is very easy to talk to and replies to questions speedily. Wishing you continued success!

testextextile –

Thank you again. Hope your business is better and better.

Алина Петров –

Liked this tester. We are so satisfied with its good performance in лобараторию. pokupayte you will not regret.