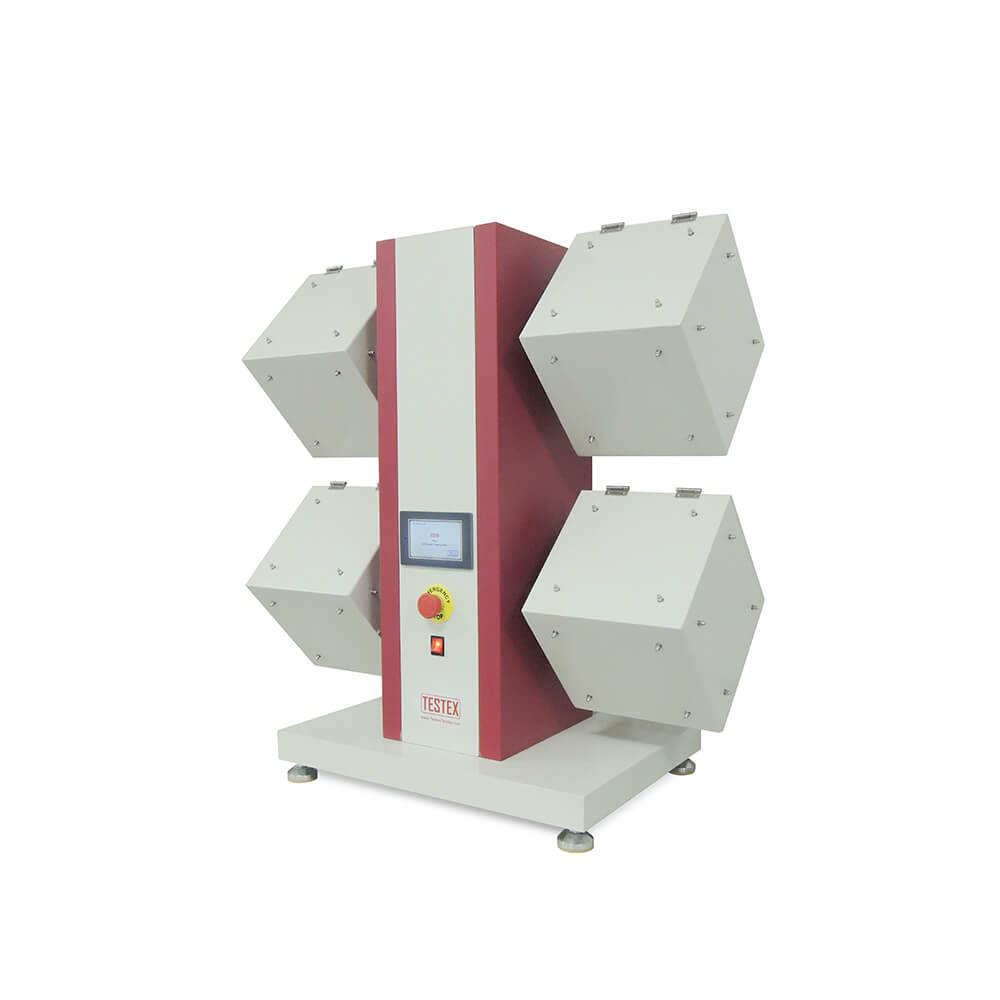

ICI Mace Snag Tester TF220

ICI Mace Snag Tester, to determine the tendency of fabrics to snag (pull yarn loops from fabric) in normal wear (mace snag). ICI Mace Snag Tester complies with ASTM D3939, etc. Please contact us for more information about snagging test.

Description

Application

ICI Mace Snag Tester. To determine the tendency of fabrics to snag (pull yarn loops from fabric) in normal wear (mace snag). Provided with 4 rotating test cylinders, fitted with sleeves of test fabric, mace balls with tungsten carbide points and controlled by a predetermined electronic counter.

A set of 4 felt sleeves are included.

Specifications

- Snag Mace Diameter: 31.75mm

- Mace Weight: 160g

- Mace Prominent length: 10mm

- Rotation Speed: 60+/-2rpm

Standard Accessories

- Measuring tape 45mm

- Take sample plate

- Wool felt cover

- Nail hammer

Optional Accessories

- Tungsten Carbide Points (Pack of 11)

- Felt Sleeves (Pack of 4)

- Snagging Photographs

Weight

| 95 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 930 mm | Width: 490 mm | Height: 390 mm |

Standards

| ASTM D3939 | JIS L1058 | GB/T 11047 |

7 reviews for ICI Mace Snag Tester TF220

You must be logged in to post a review.

ASTM D3939 Standard Test Method for Snagging Resistance of Fabrics (Mace Snagging Test Method)

Definition

Fabric snagging is a common phenomenon that the defect of the fabric which is caused by plucking and pulling and so forth. Studying the snagging in fabric, which meaning is to figure out how to prevent the fabric snagging by testing the snag resistant of the fabric.

Theory

Place the cylindrical specimen on the rotary drum. The mace makes the specimen snag by flipping and bouncing on the specimen surface when the drum rotates. The degree of the snagging is influenced by many factors. The test sample can be compared with the standard sample or sample photo to evaluate the degree of the snagging. The visual resistance level of the snagging is divided into the rank scale from No.5 (No obvious snagging) to NO.1 (severe snagging).

Preparation

- Template: Weft knitted Fabrics 205mmx330mm or 8x13in, warp knitted and woven fabrics 205mmx320mm or 8x12.5in.

- Felt sleeve, Green s/924 (70% wool, 30% rayon) 1.6mm or 1/16in thick, gram weighs about 235g/m2or 7.0 Oz/yd2.

- Spacer Plate: To set the hammer position.

- Rubber Ring: To fix the specimen

- Sewing Thread: Cotton, line number from 30 to 50 or the same thickness of polyester/ cotton.

- Standard Calibrated Fabric: The determined level of the reference fabric is provided by the purchaser or supplier.

- Standard Sample Photograph: NO.1 ~NO.5

- Specimen: When test the snagging of the fabric after washing or dry cleaning, we need to wash or dry clean the sample in the following way, and then cuts to the sample.

The washing method is as follows: the weight of the specimen with the accompanied fabric is 3.5kg or 8LB. The accompanied fabric must be the same as the specimen with the same production process and pre-treatment.

Mace Snagging Test Procedure

- The rotary drum is embedded by the felt sleeve, and then remove the extra water with the wet felt sleeve and make it dry out. If necessary, it can be heated slightly to accelerate drying. The felt sleeve will tightly embed on the rotary drum.

- Adjust the temperature to 21±1℃ and the humidity to 65±2% for at least 4 hours.

- Check whether the specimen has the flaw which will impact the test, such as accidental snagging and pilling, etc. The specimen should be replaced if it is no qualified. If the specimen cannot be replaced (for example, the fabric ball after washing), the defect should be noted and the performance of the snagging resistant is evaluated.

- The specimen is carefully placed on the rotating drum and it should face out. The seam edge should be spread out to tow sides to smooth the seam, and then use 25mm wide tape which half is pasted to the fabric and another half is pasted to the drum. (Or use a rubber ring to fix at both ends of the specimen in the ICI method)

- If the machine has more than one rotating drum, the length of half of the specimen should be the same, and the width of another half of the specimen should be the same.

- Place the mace on the drum and make it rotate freely.

- Set the specified 600 rpm, start the tester.

- Remove the specimen and place the seam on the back of the specimen.

Result

- Use standard Sample Photograph to evaluate the sample. No.5 is no obvious snagging and NO.1 is severe snagging.

- The snagging can be divided into three types:

- The snagging is protruding but no deformation.

- The snagging has deformation but not protruding.

- The snagging has both protruding and deformation.

In the test of the snagging, the protruding refers to a group of fiber, yarn or yarn segment of the fabric is out of the fabric surface.

In the test of the snagging, deformation refers to a group of fiber, yarn or yarn segment of the fabric surface moves so that the appearance of the fabric has an obvious change. But the fiber, yarn or yarn segment does not protrude the fabric surface.

In the test of the snagging, the color contrast refers to the color of the snagging of the fabric is different from the surrounding color. Its color has an obvious change and the snagging of the printed fabric is easy to occur the change of the color.

- When evaluating the snagging of the fabric, it is also necessary to observe whether there is a particularly large protrusion (greater than 4mm), large deformation (greater than 15mm) and particularly obvious color change. If more than half of the samples have above three phenomena, they should be noted in the report. The difference in the standard is only the protruding quantity. If at least half of the samples have a small snagging or deformation (less than 15mm or 6in), they should be indicated in the report.

Report

- Describe the specifications, materials of the specimen and the sampling methods.

- Specimen preparation methods include washing and dry cleaning methods.

- The test procedure is method ABC or ICI.

- If it is not a prescribed 600 rpm, please report the revolution of the test and standard sample and rating equipment.

- Whether the specimen is ironing or not and the ironing temperature.

- Report the average grade of the snagging resistance in the direction of the length and width of the sample.

[contact-form-7 id="16355" title="Inquiry"]

Q: What light source is suitable for the test results of TF220?

A: According to the requirements of the standard, it is CWF light source.

A: According to the requirements of the standard, it is CWF light source.

Ursula Dorothea –

Machine is OK. The delivery period is a bit long.

Chad Maria –

It is extremely accurate and trust worthy. I highly recommend this machine if you make a snagging test.

Michell Robin –

I am satisfied with your serve

Peter Thomson –

Like this seller!

Florence Sheridan –

The manufacturer of the snagging tester serves us with the good manner. I’m so satisfied with it! Good!

Chad Sawyer –

O produto chegou antes do que eu esperava, a qualidade é ótima, recomendo o vendedor e o produto.

testextextile –

Thank you for your support. Look forward to your next visit.

Donald John –

All very good! the seller is very sociable and quickly respond to all questions!