Fabric Shrinkage Rate Tester | A smart instrument developed by the sister company ChiuVention.

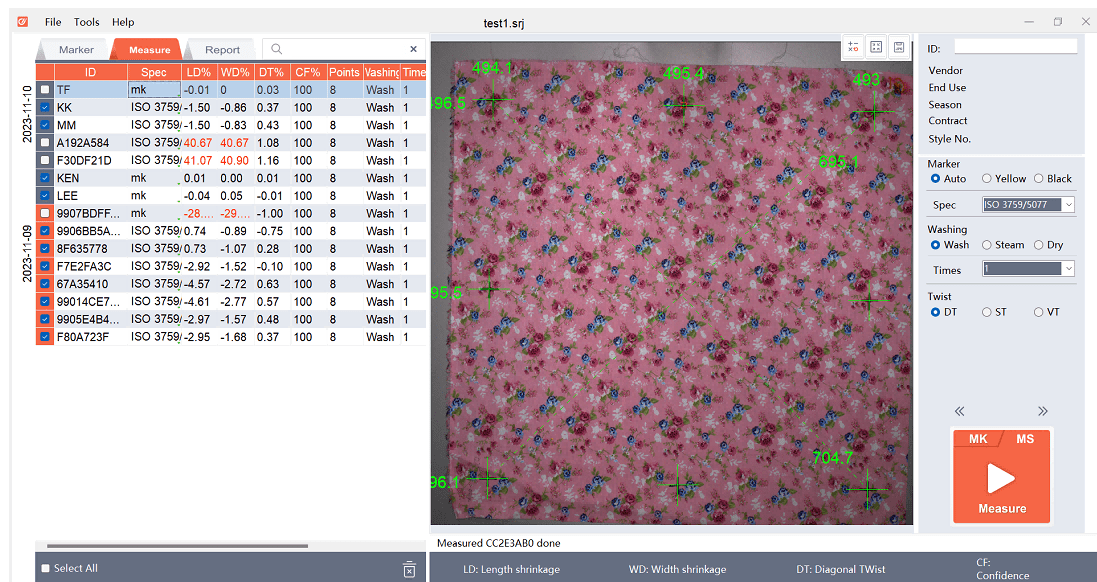

SmartShrink Shrinkage Rate Tester determines multiple shrinkage rate test results in 5 seconds for fabrics after washing, steaming, and dry-cleaning. SmartShrink takes a picture of a fabric sample by using a camera equipped on the top, automatically measuring the distances between the marked dots, and calculates the test results by the patented vision inspection algorithm of ChiuVention. The test results will be shared with the IoT-connected SmarTexLab app installed on the computer and smartphone.

SmartShrink automatically measures fabric shrinkage and calculates the test results, avoiding manual errors and making the test more accurate and reliable; It automatically saves the test data and sample photos, and can share and send the test results in real-time, making the test more transparent and trustworthy; The whole process of the test has been reduced from 6 minutes to only 5 seconds, making the test more rapid and reducing the cost by more than 90%.

Description

The test results are more accurate and reliable.

By using SmartShrink Shrinkage Rate Tester, the test sample is photographed with a high-definition camera, and the distances between the marked dots are automatically measured, The shrinkage rate is calculated with a unique algorithm, yielding all test results in real-time accurately.

Save $30,000/year for textile testing labs.

In the conventional process, for each sample to be tested for shrinkage, it takes 6 minutes to finish the work: measuring and recording before/after washing, calculating, typing the data into the computer, printing the report, etc., while SmartShrink can do all the work above in just 5 seconds.

Output multiple data at one time, reflecting the quality of fabric more comprehensively and objectively.

Warp and weft shrinkage, seam twist rate, vertical twist rate, and diagonal twist rate can be output at one time, including credibility rating for the test results. It can evaluate the quality of the fabric more comprehensively.

Famous brands are using SmartShrink.

International brands and authoritative testing institutions such as Anta, Adidas, Texwinca, and ITS have widely used SmartShrink Shrinkage Rate Tester.

Can be connected to an ERP or LIMS system.

The test results can be directly uploaded to the factory’s ERP or laboratory LIMS system. SmartShrink Fabric Shrinkage Test Machine can help you manage shrinkage test data conveniently and efficiently.

Why update your fabric shrinkage test method?

| Conventional Fabric Shrinkage Rate Testing Process |

SmartShrink Fabric Shrinkage Rate Testing Process

|

| 1. Mark the dots and wash the sample; 2. Place the fabric sample flat on the working table; and measure the distances between the dots by Shrinkage Template Scale; 3. Calculate the shrinkage rate manually based on the Fabric Shrinkage Formula and record it on the label; 4. Summarize the Fabric Shrinkage Rate data and fill in the form; 5. Type the fabric shrink data into the computer. | 1. Before washing, mark the dots and use this machine to scan the code of the fabric sample to identify the sample information; 2. After the washing, place the sample flat on the platform of SmartShrink Fabric Shrinkage Rate Tester, and the camera above automatically collects the distances between the dots on the warp and weft directions of the fabric; 3. The Fabric Shrinkage Rate Tester will calculate the shrinkage rate automatically in real-time by the computer software and save the shrinkage rate test results to form a report.

|

| Time – Consuming of Conventional Testing Process: Over 6 minutes! Time – Consuming of SmartShrink Testing Process: Only 5 seconds! | |

| According to the conventional process, for a lab that tests 200 samples per day, it takes 20 hours to complete the whole work, and more than 2 people are required; while using this new Fabric Shrinkage Test Method and machine, it only takes 16 minutes. Therefore, the Fabric Shrinkage Rate Tester can save more than 2 labor costs for the lab. | |

| Conventional Fabric Shrinkage Rate Testing Manual operation, the greater the workload, the higher the error rate! SmartShrink Fabric Shrinkage Rate Testing Smart and Auto measurement, more accurate and faster, with a lower error rate! | |

Why choose SmartShrink Shrinkage Rate Tester

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High reproducibility:

Whether is the same set of samples, or different machines of the same model, after multiple tests, the results are consistent.

Longer service life:

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure the expected service life.

User-friendly transparent warranty policy:

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for the SmartShrink Shrinkage Rate Tester. So feel free to contact our service team with any questions you may have.

Welcome to TESTEX – a professional textile testing instrument supplier – SmartShrink Shrinkage Rate Tester is on sale, contact us to get a detailed price quote.

7 reviews for Fabric Shrinkage Rate Tester | A smart instrument developed by the sister company ChiuVention.

You must be logged in to post a review.

What is Fabric Shrinkage?

Fabric shrinkage is a common phenomenon that the defect of the fabric which is subjected to home laundering procedures. To determine the quality of the fabric, shrinkage is an important element which is needed to consider. There are many elements to affect the dimensional changes of the fabrics such as the washing temperature, rinse temperature, dying procedures, etc.

Scope and Purpose of Fabrics Shrinkage Test

The shrinkage rate of textiles is an important item which must be tested in the textile industry of every country at present. At present, the countries with different standards of shrinkage rate of textiles carry out their own standards.

This testing method is suitable for the size change of woven fabric and knitted fabric after multiple household washing, and the shrinkage of various textiles after washing by conventional household washing method is detected.

Marking

Place the specimen on the measuring table and make at least three pairs of marks on it in both length and width directions. Ensure that the distance between the marks of each pair is at least 350mm, that no mark is less than 50mm from the edges of the specimen and that the measuring points are regularly spaced across the specimen.

Test Method

Lay the specimen flat on the smooth, flat surface and remove wrinkles without stretching the specimen. Place the ruler on the specimen, taking care to avoid distortion of the specimen. Record the distance between the pairs of marks to the nearest 1mm. Flatten the wrinkled specimen by the instrument so that the measurement does not cause deviation.

Report Content

The change rate of the dimension in the direction of length and the width direction, taking the average value of each measurement.

Describe the laundry conditions used, including water level, water temperature, and laundry procedure.

Describe the dry conditions used, including drying procedures and temperature.

Explain the appearance change of the test sample after washing.

How to test shrinkage? Through this article, I think you might have got some information. If you want to know more, please contact us. As a professional supplier of textile instruments, we are committed to continually improve the user experience, TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

[contact-form-7 id="16355" title="Inquiry"]

SmartShrink offers automated, precise shrinkage calculations with real-time results, digital data logging, and versatility across various fabrics, while providing consistent, repeatable results and user-friendly operation—making it far more efficient and reliable than the manual, time-consuming, and less accurate conventional shrinkage template.

What is Shrinkage Formula in Textile?

The shrinkage formula in textiles is used to calculate the percentage reduction in the dimensions of fabric after it undergoes processes like washing, drying, or exposure to heat. The formula is:

Shrinkage (%)=Original Dimension−Final DimensionOriginal Dimension/Original Dimension x 100

Explanation:

Original Dimension: The initial measurement of the fabric before testing (e.g., length or width in centimeters or inches).

Final Dimension: The measurement of the fabric after the test (after washing or drying).

Shrinkage (%): The percentage of shrinkage in the fabric.

Example:

If a fabric has an original length of 100 cm and a final length of 95 cm after washing:

Shrinkage (%)=100 cm−95 cm/100 cm×100=5%

This means the fabric shrank by 5%.

What causes fabric shrinkage?

Raw Materials: Different raw materials for fabrics result in different shrinkage rates. Generally, fibers with high moisture absorption expand when soaked, increasing their diameter and shortening their length, leading to greater shrinkage. For example, viscose fibers can absorb up to 13% moisture, while synthetic fibers have poor moisture absorption, resulting in lower shrinkage rates.

Density: The density of the fabric influences its shrinkage rate. If the warp and weft densities are similar, their shrinkage rates will also be close. Fabrics with high warp density will experience more shrinkage in the warp direction, while fabrics with greater weft density will have more shrinkage in the weft direction.

Yarn Count: The thickness of the yarn affects the shrinkage rate. Fabrics made from thicker yarns will have a higher shrinkage rate, while those made from finer yarns will experience less shrinkage.

Production Process: Different production processes result in varying shrinkage rates. Generally, fabrics that undergo multiple stretching during weaving and dyeing, combined with longer processing times and higher applied tension, will exhibit greater shrinkage, and vice versa.

Fiber Composition: Natural plant fibers (such as cotton and linen) and regenerated plant fibers (like viscose) tend to absorb moisture and expand more easily than synthetic fibers (such as polyester and acrylic), resulting in higher shrinkage rates. Wool, due to the scaly structure on its fibers, is also prone to felting, affecting its dimensional stability.

Fabric Structure: Typically, woven fabrics have better dimensional stability than knitted fabrics, and high-density fabrics are more stable than low-density ones. In woven fabrics, plain weaves usually have lower shrinkage rates than fleece fabrics, while in knitted fabrics, plain stitches shrink less than ribbed stitches. During the production process, fabrics inevitably experience stretching during dyeing, printing, and finishing, which creates tension. When the fabric is exposed to water, this tension is easily released, leading to shrinkage. Pre-shrinking is commonly used to address this issue.

Washing and Care Process: The washing, drying, and ironing processes can all affect the shrinkage of fabrics. For instance, hand-washed samples tend to have better dimensional stability than machine-washed ones, and washing temperature also impacts stability. Generally, higher temperatures lead to lower stability.

What are fabric shrinkage standards?

Fabric shrinkage standards are established guidelines, such as AATCC 135, ASTM D standards, ISO 5077, BS EN 14421, and JIS L 1096.

What is the shrinkage rate of general fabrics?

The shrinkage rates of general fabrics can vary widely depending on the fiber composition, weave, and finishing processes. The shrinkage rates for general fabrics are as follows:

Cotton: 4% to 10%

Synthetic Fibers: 4% to 8%

Cotton-Polyester Blends: 3.5% to 5.5%

Natural White Fabric: 3%

Wool Denim: 3% to 4%

Sateen: 3% to 4.5%

Printed Fabric: 3% to 3.5%

Twill Fabric: 4%

Workwear Fabric: 10%

Rayon: 10%

What is the detailed fabric shrinkage test procedure?

1 Sample Preparation

Select Fabric Samples: Cut the fabric into standardized dimensions (e.g., 30 cm x 30 cm) to ensure uniformity.

Mark Samples: Use a fabric marker to mark the original dimensions and any reference points on the fabric.

2 Pre-Treatment (Optional)

Pre-Wash Samples: If required, pre-wash the samples according to the care instructions to remove any finishes that could affect the results.

3 Initial Measurement

Measure Dimensions: Use a ruler or fabric measuring tape to measure the length and width of each sample accurately. Record the dimensions (L1 and W1).

4 Washing Procedure

Select Washing Conditions: Define the washing method, including water temperature, detergent type, and cycle duration based on relevant standards (e.g., AATCC or ISO).

Wash Samples: Place the fabric samples in a washing machine and run the cycle according to the chosen conditions.

5 Drying Procedure

Drying Method: After washing, dry the samples according to the specified method (e.g., tumble dry, line dry, or air dry).

Avoid Over-drying: Ensure not to over-dry the samples, as this can impact the accuracy of the results.

6 Post-Wash Measurement

Measure Dimensions Again: After drying, measure the dimensions of each sample (L2 and W2) using the same method as the initial measurement.

Record Results: Note the dimensions after washing and drying.

7 Calculating Shrinkage Rate

Use the SmartShrink Shrinkage Rate Tester.

8 Analysis and Reporting

Analyze Results: Compare the calculated shrinkage rates against applicable standards to evaluate fabric performance.

Prepare a Report: Document the test conditions, methods, measurements, calculations, and findings for quality control and compliance purposes.

What types of fabrics are suitable for the dry shrinkage rate testing method and the wet shrinkage rate testing method?

The dry shrinkage rate testing method is suitable for synthetic fibers (such as polyester and nylon) and certain high-performance fabrics, while the wet shrinkage rate testing method is more appropriate for natural fibers (such as cotton and wool) as well as most common fabrics.

Can the SmartShrink handle different fabric types?

Yes, the SmartShrink can handle different fabric types, including natural fibers (like cotton and wool), synthetic fibers (such as polyester and nylon), blended fabrics, and technical fabrics, ensuring accurate and reliable shrinkage measurements for a wide range of textiles.

Can the testing results be integrated with production software?

Yes, the test results can be directly uploaded to the factory’s ERP or laboratory LIMS system.

Pitt –

A very simple and practical instrument, a pleasant shopping.

Harriet Yonng –

Very useful. Thanks manufacturer!

Egbert Fielding –

Good manufacturer. The price is also reasonable.

Ira Birrell –

I got a great scale. Thanks manufacturer!

Una Maltz –

The Shrinkage Scale & Template is light and accurate. This is exactly what I want.

Huggins –

Ottimo prodotto venditore molto gentile

Laurel Rebecca –

Chegou fast bem, aínda não montei. I hope that esteja tudo working, pleasing.