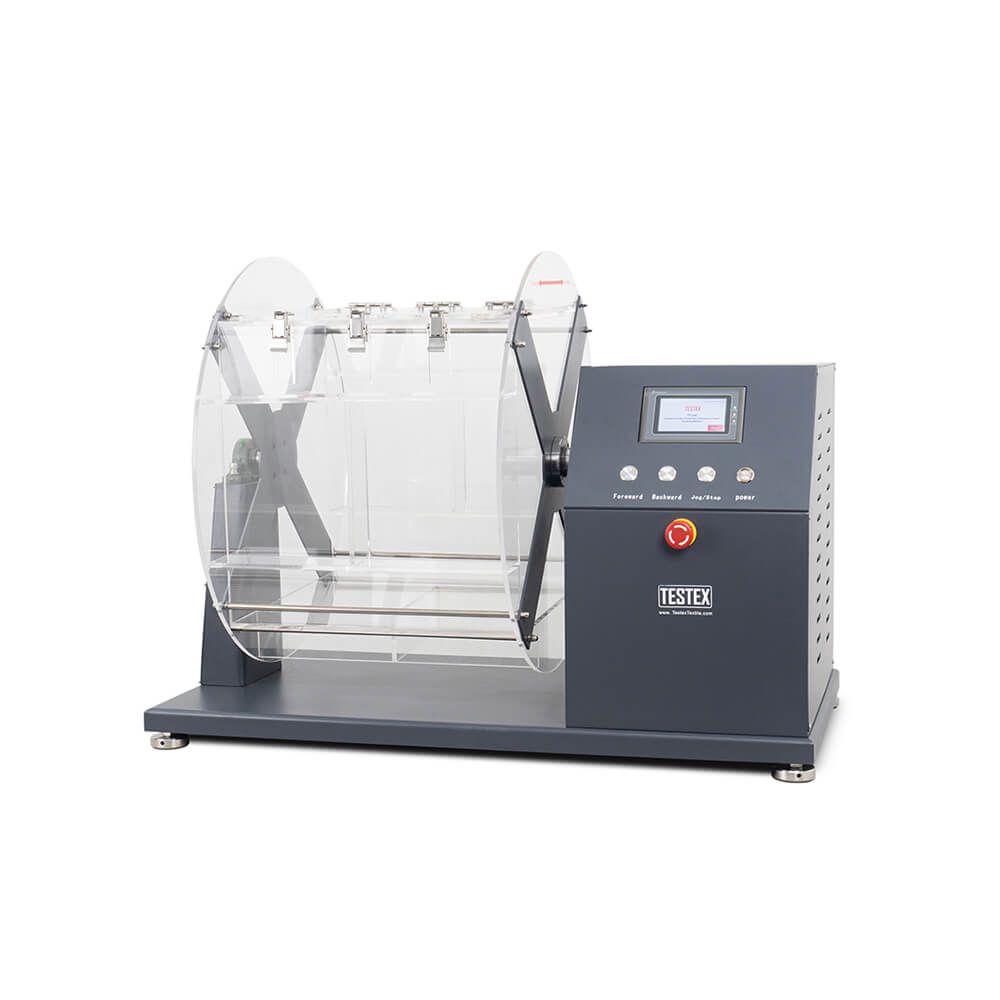

SPI Flammability Tester (Vinyl Material) TF318

SPI Flammability Tester is used to determine the ignition properties of vinyl plastic film material. SPI Flammability Tester complies with CFR 16 Part 1611, etc.

Description

Application

SPI Flammability Tester (Vinyl Material), is designed to determine the ignition properties of vinyl plastic film material. In addition, it complies with the standards proposed in the CFR 16 Part 1611 – U.S.A. Flammable Fabrics Act for flammability of apparel vinyl plastic film. Many countries have made related requirements for the flammability of textiles. As a result, there is a great need for such testing instruments. If you are looking for a flammability testing machine, then it will be your top choice.

Moreover, the SPI Flammability owns stainless steel cabinet with a transparent viewing window. Besides, you can adjust the flame length based on your need. In other words, adjustable flame length is available. However, the burning rate shall not exceed 1.2 in./s as judged by the average of five determinations lengthwise and five determinations transverse to the direction of processing when the specimen is placed at an angle of 45 degrees and exposed to the standardized flame (22# fire nozzle, 1/2 inch. in length). Therefore, when using SPI Flammability, you should take care of the details of the operation.

Specifications

- The most advanced thread locking device and sample holder save 80% of operation time that faster than other suppliers’ design

- Equipped with photoelectricity sensor accurately and automatically record burning time with no damage ensures 5 years of life or longer

- Timer accuracy up to 0.01 seconds;

- 22# needle flame, 9/16inch from the specimen, flame length adjusted by flow-valve;

- Timing distance of burning 6 inch

Standard Accessories

- Specimen Fixture

- Flame measuring tape

- Sampling plate

- Optional Accessories: Specimen Fixture

Power

| 220 / 110 V | 50 / 60 Hz |

Weight

| 25 kg |

Dimensions

| Length: 400 mm | Width: 410 mm | Height: 550 mm |

Standards

| CFR 16 Part 1611 |

Welcome to TESTEX – a professional textile testing instrument supplier – SPI Flammability Tester TF318 is on sale, contact us to get a detailed price quote.

6 reviews for SPI Flammability Tester (Vinyl Material) TF318

You must be logged in to post a review.

Applicable Range of Vinyl Plastic Film Combustion

The United States Flammable Fabrics Act (FFA) requires that all relevant textiles for sale in the United States be tested and meet its specified requirements for flame retardancy. The flammability standard for vinyl plastic films (16 CFR 1611) is used to detect non-rigid polyethylene plastic films (including transparent, translucent and opaque, flat and uneven surfaces, molded or surface treated) and the thickness of polyethylene film less than or equal to 0.33mm.

Requirements for Flammability of Vinyl Plastic Film

The average burning rate for each of the five longitudinal samples and five transverse samples is required not to exceed 3 cm/s, use the SPI flammability tester and test according to the test program specified in the standard (45-degree flammability test method).

Related standards for the flammability of vinyl plastic film

16 CFR Part 1610 Standard for the Flammability of Clothing Textiles

16CFR 1615(Size 0-6), 16CFR1616 (Size 7-14) Standards for the Flammability of Children's Sleepwear

NFPA 701:2010 Standard Methods of Fire Tests for Flame Propagation of Textiles and Films

CAN/CGSB-4.2 No. 27.5-2008 Textile Test Methods Flame Resistance — 45° Test — One-Second Flame Impingement

Test Principle

measure smoldering time and after flame time and the length of burned part for textiles after the extinguishment of the flame when the textiles are exposed to flame for a certain time following specific methods. The shorter the smoldering time and after-flame time are and the length of the burned part, the better the retardant flammability of the textiles.

Test Procedure

1 Cut the sample according to the rules, then wrap the clip with cotton thread to press the switch trigger at least 0.25 inch from the edge of the clip. The wire passes through the hole under the upper clip, so that the line clings to the sample when the sample clip is closed.

2 The sample is inserted into the sample clip. When the clip is closed, the sample cannot be wrinkled or deformed. The sample must not exceed the outer edge of the lower clip, otherwise, the clip cannot glide smoothly on the track when placed in the box.

3 Both electronic switches are ready for automatic timing before the sample and the sample clips are placed in the box. Adjust the knob to adjust the flame to 0.5 inches.

4 Turn off the ventilator fan, and timer zero, adjust the flame to the above requirements, and close the door, sample clip inserts to the box to reach the burning position.

5 The first timer will start timing automatically once the sample holder contacts the sensor. The second timer will start timing automatically once the first marking line is burned. Both two timers will stop automatically once the second marking line is burned. Press the ON/OFF button to close the valve of the gas supply and record the time and calculate the burning rate.

Grading the burning rate of textiles:

It is important to grade the textiles according to the average burning time, which is shown in the below table.

Grade | Nap-free fabric | Suede fabric |

1 | Average burning time ≥3.5s | Average burning time>7.0s; Average burning time 0s-7s, no burning of the base cloth with fast burning on the surface |

2 | \ | Average burning time 4s-7s, the burning of the base cloth |

| 3 | Average burning time<3.5s | Average burning time<4.0s, the burning of the base cloth |

[contact-form-7 id="16355" title="Inquiry"]

Sophia Rossetti –

Timely delivery, everything one needs in one neat package.

Tammy Richardson –

Great value. Made very well!

Daphne Hughes –

Well made, reasonable price, Recommend.

Moira Hearst –

Fast delivery, full package, good manufacturer!

testextextile –

Thanks for your appreciation!

Bertha Anthony –

Excellent! Thanks manufacturer.

Isabelle –

¡Llegó muy rápido! ¡gracias!