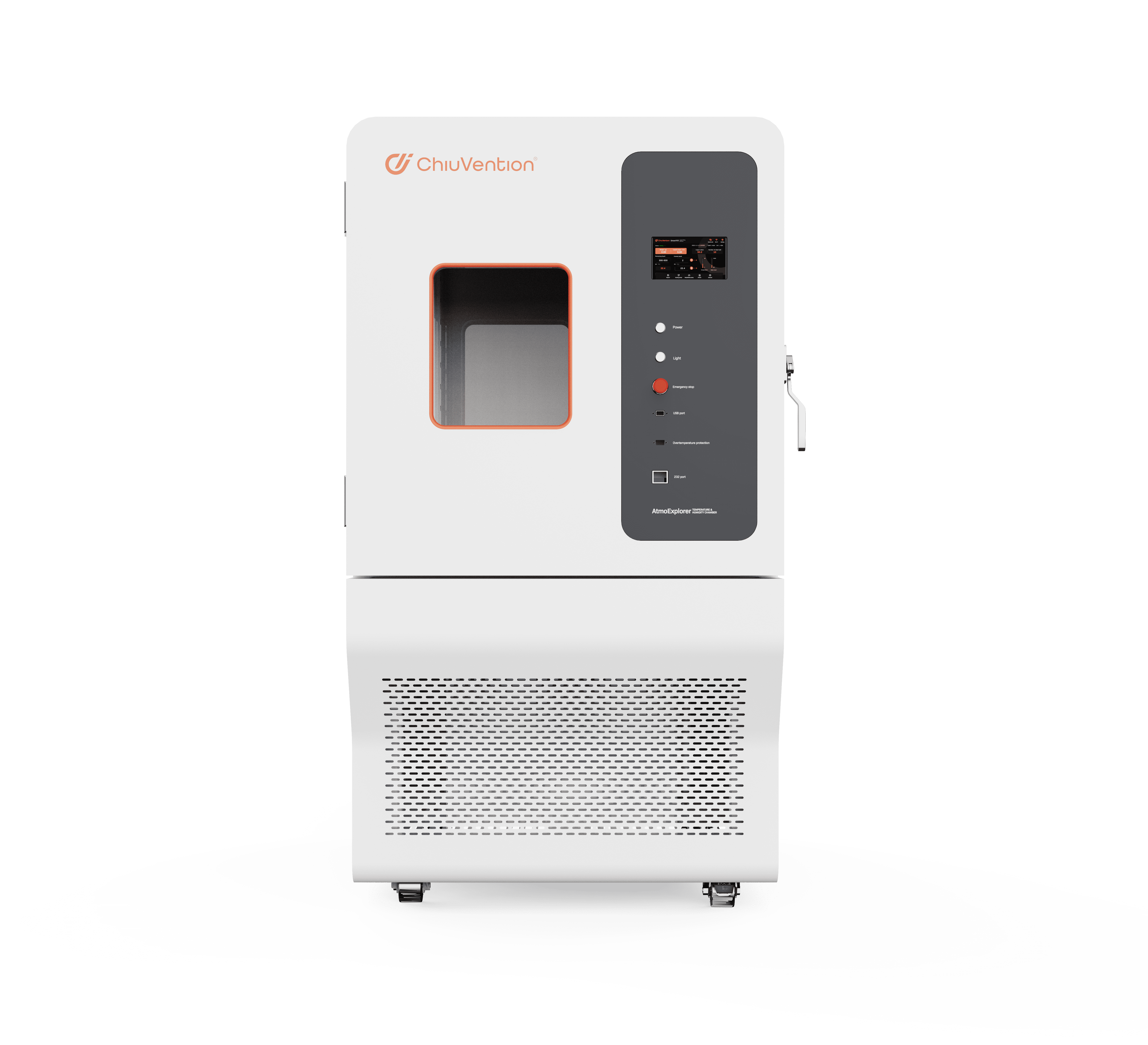

AtmoExplorer Temperature and Humidity Chamber | This is a newly developed product by the sister company ChiuVention.

The AtmoExplorer Temperature Humidity and Chamber, also known as the climate chamber, or temperature humidity test chamber, is used to test the performance of materials in a variety of environments, such as testing materials’ heat resistance, cold resistance, dry resistance, and moisture resistance performance.

The AtmoExplorer climate chamber is applicable for temperature and humidity tests for lots of products, such as electronics, electrical appliances, mobile phones, communication devices, instruments, vehicles, plastic products, metals, food, chemicals, construction materials, medical equipment, and aerospace products. We are a professional Temp Humidity Chamber manufacturer, get a factory humidity chamber price now!

Description

Overview of Temperature and Humidity Chamber

Our temp and humidity chamber is excellent on temperature-humidity control, including high-temperature and low-temperature control, high-humidity and low-humidity control. Besides, our AtmoExplorer Temp and Humidity Chamber can execute different temperature and humidity commands during different periods, etc. You can contact us now for more choices of climate chambers, such as Thermal Shock Chamber, HAST chamber, and temperature chamber.

For humidity test chamber price or humidity conditioning chamber price, welcome click the What’s App right corner now!

Application Industry of Temperature Humidity Chamber

| electronics | Yarn | plastic | Rubber | Fiber |

|---|---|---|---|---|

Features of AtmoExplorer Temperature & Humidity Chamber

Wide range of applications

This climate chamber replicates extreme environments, including high and low temperatures, as well as high and low humidity levels. It meets the testing demands of diverse fields and industries, such as electronics, materials research, medicine, automobiles, and food.

Excellent performance on control precision and uniformity of temperature and humidity

Temperature and humidity control precision: ±0.5℃; ±3%RH

Temperature and humidity uniformity: ±2℃; ±5.0%RH

This constant temperature humidity chamber can provide accurate conditions for environmental tests for materials.

Achieve heating and cooling quickly

When unloaded, this temperature and humidity chamber can achieve heating from room temperature to 100℃ within 30 minutes,

It can also achieve cooling from room temperature to -20℃ within 60 minutes.

Intuitive and practical screen, easy to operate

This humidity environmental chamber has a 7-inch large touch screen that displays information in both Chinese and English. The set values (SV) and perform values (PV) of temperature and humidity are displayed directly, as well as the currently executing program number, segment information, remaining time, and number of cycles.

Stable operation originated from high-quality insulation materials and humidifiers

The heating element of this temperature and humidity chamber is made of spring-type nickel-chromium wire, and the humidifier is a UL-shaped humidifier in the form of stainless steel electric steam generation.

High-quality refrigeration system and refrigeration auxiliary parts

Tecumseh fully hermetic high-efficiency compressor from France, solenoid valve from Japan, and pressure controller & oil separator are international brands. So AtmoExplorer Climate test machine can conduct tests related to temperature and humidity smoothly.

A variety of safety protection

This environmental control chamber is equipped with enough protection settings.

The burn prevention switch, the high-pressure protection for the compressor, the overheating protection for the compressor,

the over-current protection for the compressor, the no-fuse switch protection, the short-term water shortage alarm, and the long-term water shortage shutdown protection.

Various sizes can be customized

such as 80L,150L,225L, 408L, 800L, and 1000L. We always know your needs and provide a variety of practical constant climate chambers for you.

Detailed Parameters of Temperature and Humidity Controlled Cabinets

| Model | Measurable temperature range | Overall dimension D*H*W(mm) | Inner Box size D*H*W(mm) | Power(KW) | Voltage / Frequency | Number of phases | Gross weight (kg) |

|---|---|---|---|---|---|---|---|

| CV340-80L | -40℃~ 150℃ -20℃~ 150℃ | 1250*1510*700 | 400*500*400 | 5.0KW 4.5KW | AC220V/50H | 1 phase/3 wire | 307 |

| CV340-150L | -40℃~ 150℃ -20℃~ 150℃ | 1350*1610*800 | 500*600*500 | 5.0KW 4.5KW | AC220V/50H | 1 phase/3 wire | 367 |

| CV340-225L | -40℃~ 150℃ -20℃~ 150℃ | 1350*1720*970 | 500*750*600 | 7.0KW 6.0KW | AC380V/50H | 3 phase/5 wire | 422 |

| CV340-408L | -40℃~ 150℃ -20℃~ 150℃ | 1450*1820*1080 | 600*850*800 | 8.0KW 7.0KW | AC380V/50H | 3 phase/5 wire | 518 |

| CV340-1000L | -40℃~ 150℃ -20℃~ 150℃ | 1850*1970*1280 | 1000*1000*1000 | 14.0KW 12.0KW | AC380V/50H | 3 phase/5 wire | 783 |

Key Specifications of Temperature and Humidity Test Chamber

| Temperature range | -20℃~+150℃ (-60℃/-40℃~+150℃ Optional) |

| Humidity range | 20%-98%R.H. |

| Temperature and humidity control accuracy | ±0.5℃;±3%RH |

| *Note: To achieve the performance above, it should be measured after 30 minutes of temperature stabilization. | |

| Temperature and humidity distribution uniformity | ±2℃; ±5.0%R.H. |

| *Note: To achieve the performance above, it should be measured at 1/6 position from each wall of the test area, and need to be measured after 30 minutes of temperature stabilization. | |

| Heating time | from room temperature to 100℃, within 30 minutes (when no load) |

| Cooling time | from room temperature down to -20℃, within 60 minutes (when no load) |

| Testable area | 500*750*600mm (D*W*H) |

| Test box door | a total of 1, single piece door, left open |

Controller specifications

Accuracy

temperature ±0.1℃ + 1digit

humidity ±1%RH + 1digit

Degree of resolution

temperature ±0.1℃, humidity ±0.1%RH

Temperature slope: 0.1~9.9 can be set.

Display the current program number, number of segments, remaining time, and number of laps

Temperature and humidity program setting value is displayed in a circular curve, with instant display of program curve execution function

Separate program editing screen, at least 4 temperature and time steps can be input on each page

Program capacity and control function.

Program group: 120 PATTENs max.

Available memory capacity: 1200 SEGMENTS.

Repeatable commands: up to 999 times for each command.

SEGMENTS time setting 0~99Hour59Min.

We also provide a temperature chamber, temperature-controlled chamber, climatic test chamber, etc.

Welcome to TESTEX – a professional textile testing instrument supplier – AtmoExplorer Temperature and Humidity Chambers are on sale, Contact us to get a temperature and humidity chamber price quote.

6 reviews for AtmoExplorer Temperature and Humidity Chamber | This is a newly developed product by the sister company ChiuVention.

You must be logged in to post a review.

The constant temperature and humidity test chamber, also known as the constant temperature and humidity test machine, or programmable heat and humidity test chamber, is used to test heat resistance, cold resistance, dry resistance, and moisture resistance of materials under a variety of environments. Constant temperature and humidity test chamber simulate high and low temperature, hot and humid environment for testing the performance of instrumentation, electronics, parts, and various materials in storage, and transportation when they are in an environment with high humidity and temperature or low humidity and temperature. Meanwhile, it is reliable testing equipment for quality control engineering.

Selection principles of the constant temperature and humidity chamber

For every environmental or reliability test, there are some strict regulations on the category of environmental factors, value, and tolerance. Moreover, environmental factors that are not needed in the test should be prevented from the test for providing the exact evidence to analyze the product failure and failure mode. As a result, the test product is only allowed to be put in the specified environment instead of any other environmental stress interference.

Environmental test equipment may carry out multiple tests of the same type of product while an engineering product under test may be put into different environmental test equipment for testing. The environmental conditions created by the environmental test equipment are required to be repeatable in order to ensure the test results are comparable which are all about the same product in the same test specification under the specified environmental test conditions.

A constant temperature and humidity chamber must accurately or similarly simulate the process of the use, storage, shipping, and other aspects of engineering products. Additionally, it must satisfy the demands of the uniformity of the temperature field and the accuracy of the temperature control in accordance with defined test specifications, requirements of test value for high temperature and low temperature, and the time of test which are specified by various types of products. We can guarantee a precise reproduction of environmental conditions in the environmental test only by doing this.

The test cycle of environmental testing, especially reliability testing, is long. Sometimes, the machine will test military products with a very high value. In the test process, the testers need to carry out the operation or test around the scene. Therefore, the environmental test equipment is required to be characterized by safe and easy operation, reliable use, long working life, and so on for the normal operation of the experiment.

The environmental conditions provided by any environmental condition must be observable and controllable, which is not only set to limit environmental parameters to a certain tolerance range, but also for the safety of the experiment in order to eliminate the unnecessary loss caused by the uncontrolled environmental condition.

Here are some regulations for the place where the constant temperature and humidity chamber is installed to facilitate the heat dissipation and maintenance of the box.

There should be 300mm between it and the nearby wall or object.

We should identify a location where the average annual temperature ranges from 15 to 35 °C and the relative humidity reach more than 85%.

There should not be a sharp change in the ambient temperature of the installation place.

It should be mounted on a smooth surface (when installing, we should confirm that it is placed horizontally by using the level).

It ought to be set up in an area with minimum dust, good ventilation, freedom from combustible or explosive items, high-temperature heat sources, or without direct sunshine.

As much as possible, it should be installed close to the power source.

A: Generally the size of temperature humidity chamber is decided according to the size of the test product, and the size of the test studio should be greater than or equal to 3 times the size of the test product to ensure that the air around the samples in the testing process can circulate sufficiently to achieve a uniform temperature and humidity environment.

Q: What is the application range of Temp and Humidity Chamber?

A: Laboratory use

Generally used in for plant culture, breeding test; bacteria, microbial culture, used as breeding, fermentation, microbial culture, a variety of constant temperature test, environmental testing, material denaturation test and culture medium, serum, drugs and other items such as storage.

It can be widely used in drug, textile, food processing and other aseptic test, widely used in medical and health care, biopharmaceutical, agricultural research, environmental protection and other research applications.

Industrial use

Generally used in electronic and electrical engineering, household appliances, automobiles, instruments and meters, electronics and chemical industry, parts, raw materials and coatings, coatings for high and low temperature, high and low humidity experiments, in the aerospace, aviation, ships, weapons, electronics, petrochemical, post and telecommunications, communications, automotive and other fields are favoured.

Q: What are the common types of constant temperature and humidity test chambers?

A: 1 Walk-in constant temperature and humidity test chamber

For large samples or batch testing, convenient for operators to enter the experiment.

Suitable for automotive parts, automotive vehicles, computer motherboards, terminals, industrial controllers, power supplies and other microelectronic circuit components life reliability test.

2 Small constant temperature and humidity test chamber

For small sample testing, widely used in laboratory and small-scale production environment.

Suitable for electronics, electrical appliances, food, hardware vehicles, chemicals, building materials, food and other industries.

3 Programmable constant temperature and humidity test chamber

With automatic control and programming function, it can set the temperature and humidity curve according to different testing requirements.

Suitable for electronics, electrical appliances, communications, instrumentation, vehicles, plastic products, metal, food, chemical, building materials, medical, aerospace and other products for quality testing.

4 High and low temperature alternating humidity test chamber

Combining high and low temperature and humidity changes, simulating extreme environmental conditions, suitable for material weathering test.

Applicable to aerospace products, information and electronic instruments and meters, materials, electricians, electronic products, various electronic components.

Q: During the humidity and heat testing process, we observed a significant discrepancy between the actual humidity and the target humidity, with the actual value being much lower. What steps can we take to address this issue?

A: Firstly, check the water supply of the humidification system, whether there is a certain amount of water in the water supply system.

Secondly, check whether the humidification boiler water level control is normal. If all of the above are normal.

At last, we have to check the electrical control system, which should be overhauled by professional maintenance personnel.

Q: How to fix when low temperatures fail to meet targets and cool down very slowly?

A: If the temperature drops very slowly, you need to check the following points.

Check whether the temp humidity chamber has been dried before doing the low temperature test, the chamber needs to be dried before the test, and then put the test sample test;

Check whether the test samples in the working chamber are placed too much, resulting in the air in the working chamber can not be fully circulated;

Check whether the refrigeration system is faulty.If the temperature reaches a certain value after a tendency to go back up

First check whether the use of constant temperature and humidity test chamber environment, equipment placed in the ambient temperature and placed in the location (after the box and the distance from the wall) to meet the requirements.

Q: In the high temperature test, the temperature change cannot reach the value of the test temperature, how to solve it?

A: If the temperature rises slowly, you need to check the wind circulation system, whether the wind circulation of the regulating flap is normally open.

If the temperature rises very quickly, check whether the motor of the wind cycle is running normally. If the temperature overshoots great then you need to adjust the PID setup parameters. If the temperature rises directly, over-temperature protection, then the controller failure, must replace the control instrument.

Q: How can we address the issue of temperature control when there is abnormal pressure?

A: First of all, you need to check the placement of the temperature and humidity controlled cabinets, whether it is more than 30cm away from the wall position, because poor heat dissipation will cause the high pressure side of the compressor is too high, so if it is caused by improper placement, you need to correctly adjust the position in a timely manner;

Secondly, check whether the temperature and humidity chamber is surrounded by sealed space, if surrounded by closed space, it will cause the environment to produce temperature rise, will also cause the high pressure side of the compressor is too high, so please keep the ventilation around;

If it is not the above faults, you need to ask a professional for overhaul.

Q: How to deal with the high-pressure alarm of the temperature and humidity test chamber?

A: 1 Check whether the site ambient temperature is too high. If the site temperature is above 30 ℃, open doors and windows or exhaust system ventilation, open air conditioning to reduce the ambient temperature;

2 Ensure that the distance between the environmental box and other objects (or walls) is greater than 60 cm for better heat dissipation. (If the air is exhausted upwards, it is necessary to install an exhaust pipe to direct the hot air outdoors.)

3 Check whether the compressor is at normal pressure value. (If the pressure is too high, discharge part of the refrigerant to make it reach the normal pressure value.)

4 Check whether the condenser is dirty and blocked. If the condenser is dirty and blocked, it will easily absorb dust and impurities, which will affect the ventilation and heat dissipation, and the condenser should be cleaned up.

5 Check whether the condensing fan is running normally. If the condensing fan is damaged and affects the wind circulation, the condensing fan should be replaced.

Mike –

This is a very practical environmental chamber with various volumes.

Jerry –

Temperature humidity chamber, well simulated temperature and humidity environment, stable testing.

James –

It is very stable!

Ronald Barney –

The Conditioning Chamber is perfect for my needs. I love the multi adjustments.

Anonymous –

reat product, works fine and well packaged

testextextile –

Thank you!It’s a pleasure to cooperate with you!

Gill –

Excellent service. Recieved very timely.

testextextile –

Thank you for your encouragement,looking forward to the next cooperation!:-)