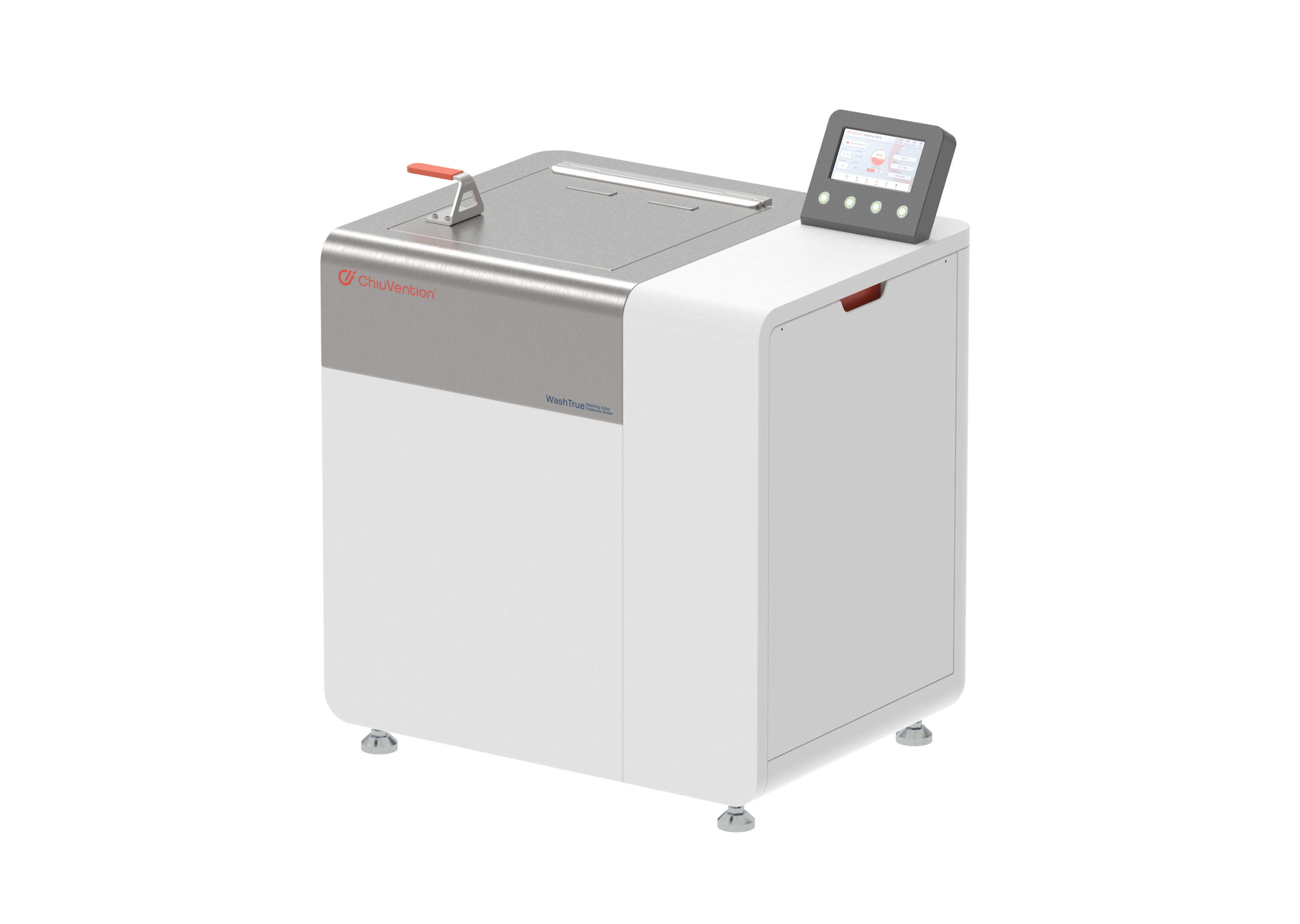

WashTrue Washing Fastness Tester | A smart instrument developed by the sister company ChiuVention.

The WashTrue Washing Fastness Tester is mainly used to test the color fastness to washing or dry cleaning, i.e., the ability of textiles not to fade or change color after washing or dry cleaning.

The WashTrue Washing Color Fastness Tester adopts a smart temperature control algorithm to ensure that the washing color fastness test meets the test standards and the results are reliable. This Washing Fastness Tester applies to standards such as ISO 105 C06:2010, AATCC61-2013e3, GB/T 12490-2014, M&S C4A, AATCC190-2010e2 (2016) e2, NEXT TM 02, etc. To speed up the sample preparation for washing fastness testing, you also need a SmartDispen Detergent Dispenser (figure 3).

A series of testing operations can be completed on the touch screen, such as selecting standards, parameters, time, and temperature settings, adding water, draining water, etc., it is smart and efficient, and the buzzer alarms automatically when the color fastness to washing test is completed. The WashTrue also has multiple safety designs and can run long time with low noise.

Description

Features of WashTrue Washing Fastness Tester

Smart, Easy to use and Efficient

The smart screen interface allows direct access to a variety of operations: selection of test standards, customization of test parameters, temperature calibration, selection of temperature increase rate, setting of time, heating temperature, etc. So it is very convenient to do the color fastness test of fabric.

Precise temperature control, more reliable washing fastness testing

Smart temperature control algorithm achieves accurate and effective test water temperature control.

Humanized design, durable

Multiple safety protection design, the test rotating frame is equipped with an anti-jamming function to protect the equipment.

The heating is achieved by solid state relay controlled electric, bringing more stable temperature and longer service life.

The water tank is made of SUS304 material, also durable. In a word, the WashTrue Washing Color Fastness Tester is reliable.

Application of WashTrue Washing Fastness Tester

Washing Color Fastness Testing is a necessary part of textile color fastness testing. So a washing fastness tester is indispensable. We can evaluate the washing color fastness of the textile quickly by using the WashTrue Washing Fastness Tester.

The WashTrue Washing Color Fastness Tester complies with a wide range of color fastness standards. Besides, the operator can choose between AATCC, ISO, and other test methods. The screen will display the corresponding parameters.

The Test Principle of Colour Fastness to Washing

Textile specimens sewn together with one or two pieces of standard lining fabric are placed in a stainless steel cup mixed with steel balls, soap or soap, and an anhydrous sodium carbonate mixture. Mechanical stirring is carried out at the specified time and temperature by the rotation of a stainless steel cup. When the colorfastness test is over, the sample will be washed and dried. Take the original sample as a reference sample, and evaluate the discoloration of the specimen and the staining of the lining fabric with gray sample cards or instruments. So we can also make perspiration test in textile.

Specifications of WashTrue Colour Fastness to Washing Tester

| Temperature setting range | Normal temperature (>0°C)~ 95°C |

| Heating Rate | 1.5±0.5℃/min |

| Temperature Accuracy | ± 2°C |

| Rotation speed | 40 ± 2 r/min |

| Distance from the bottom of the cup to the rotary axis | 45 ±10 mm |

Standard Accessories

Test steel cup 550±50mL or 1200±50mL 12 pcs

Stainless steel ball φ6±0.5mm 200pcs

Fuse 380V 32A 4pcs

Inlet pipe 1pc

Drain pipe 1pc

Tape 1pc

Screwdriver 1pc

Throat hoop 1pc

Sampling plate 40 x 100 mm 50 x 100 mm 50 x 150 mm 3pcs

Rubber gloves 1pc

ISO sealing or AATCC sealing 12 pcs

Measuring cup 100ml 1pc

Optional Accessories

Test steel cup 550±50mL 1pc

Test steel cup 1200±50mL 1pc

Stainless steel ball φ6±0.5mm 1pc

Stainless steel sheet φ30±2mm

thickness 3±0.5mm 1pc

ISO color change gray card 1pc

ISO color change gray card 1pc

AATCC color change gray card 1pc

DW Multi-Fiber Cloth 50m/box 1pc

AATCC No.10 Multi-Fiber Cloth 25m/roll 1pc

Standards of WashTrue Colour Fastness to Washing Tester

Standards

ISO 105 C06:2010, AATCC 61-2013e3, GB/T 12490-2014,

ISO 105-C08-2010,GB/T 29255-2012,ISO 105-C09-2010/amd.1:2003,

GB /T 23343-2009,ISO 105 C10:2006,GB /T 3921-2008,

ISO 105-E03:2010,ISO 105-E12:2010,M&S C4A,

AATCC 190-2010e2(2016)e2,NEXT TM 02

Optional Standards

ISO 105-D01:2010

GB/T 5711-2015 AATCC 132-2004e3

Power of WashTrue Colour Fastness to Washing Tester

| AC 220V 3N AC 380V 3N | 50/60 Hz 50/60 Hz | 40 A 23 A |

Weight of WashTrue Colour Fastness to Washing Tester

| 150 kg |

Dimensions of WashTrue Colour Fastness to Washing Tester

| Length: 860 mm | Width: 720 mm | Height: 1060 mm |

Welcome to TESTEX – a professional textile testing instrument supplier – WashTrue Washing Fastness Tester is on sale, contact us to get a detailed price quote.

11 reviews for WashTrue Washing Fastness Tester | A smart instrument developed by the sister company ChiuVention.

You must be logged in to post a review.

The Importance of Color Fastness Testing

Colorfastness refers to the washing and friction resistance of textiles. The quality of color fastness is directly related to the health and safety of the human body. In the process of using the product with poor color fastness, when the products across the rain and the sweat, which will result in the pigment on the fabric fading off, even the molecules and heavy metal may be absorbed by the human body through the skin and endanger the health of the skin. On the other hand, cloth with poor color fastness will cause other clothes to be stained with color and dye other clothes when washed with other clothes.

What is the difference between water fastness and washing fastness?

Water fastness is the color fastness of water immersion. In the testing, the textile specimen and the specified lining fabric are laminated together and immersed in water. After squeezing out the water, place them in the middle of the two plates and offer a certain pressure. Finally, use the gray sample card or instrument to assess the color change of the specimen and lining staining.

Washing fastness is also called soap fastness. In the testing, sewn the textile specimen and the specified lining fabric together. Then place them in soap or a mixture of soap and anhydrous sodium carbonate. Finally, use the gray sample card or instrument to assess the color change of the specimen and lining staining after a specific washing, cleaning, and drying with the original sample as a reference. In short, the sample needs to be immersed in the water in the former testing while it needs to be washed with soap in the latter testing.

Test Standard for Colour Fastness to Washing of Textiles

The washing fastness of textiles refers to the ability of the textile to maintain the original color under the washing condition, that is, the ability to not fade and change color. ISO 105C01-C05 provides several test methods for color fastness to washing, covering the range from mild to intense washing operation, as a classic colorfastness test method, which is still widely used today. The determination of color fastness to washing of the whole cotton fabric using washing fastness test ISO 105-c03 method, China’s GB/T 3921 3-1997 standard is based on the modification of the formulation, so its technical content and international standards are not different, applicable to any form of textiles.

In addition to the above 2 standards, there are many international standards on the testing of color fastness to water, such as AATCC 61-1A of the US, British BS 1006-C01, ISO 105-c06 of the ISO, JIS L0844 of Japan, etc.

Test Procedure

1 Set the working temp and working time as the standard requirement.

2 Add the detergent solution and steel balls to the cylinder as per standard requirements.

3 Place an equal number of washpots on each side of the shaft. Start the motor rotation and run for at least 2 min to preheat.

4 After preheating, put the ready samples into the washpots sequential and clamp the lid. Start the machine and run at 40 rpm for a certain amount of time.

5 After the machine stops running, the sample should be washed with distilled water or ionic water, the excess moisture is extracted by centrifuge, and the sample is dried by a possible method.

6 Evaluate the sample according to the standard sample.

As a professional manufacturer of washing fastness testers, we test every washing fastness tester according to the test standard to ensure the normal operation of the instrument. If you want to know the price of the washing color fastness tester, please contact us.

Notes:

1 Be careful about dealing with all chemicals.

2 Test result rating must be completed in a standard light box.

3 Test solutions should be prepared and used at present according to the need.

4 There should be safety rain shower facilities prepared nearby for emergency use.

5 A rapid drainage system should be installed and equipped with a sewage treatment tank.

6 It is important to follow laboratory practices and wear protective eyewear in the laboratory.

7 When operating the instrument, we should refer to the safety instructions of the instrument manufacturer.

8 The reference detergent which is specified in AATCC 1993 standard can be allergenic. Thus we need to prevent them from touching eyes and skin.

A: The washing fastness of textiles refers to the ability of textiles to not fade and change color after washing or dry cleaning.

Q: How to improve the color fastness of washing in industrial production?

A: The most direct solution to fading in production is to use color fixers, such as resins or quaternary ammonium salts, which strengthen the connection between the dye and the fiber, enhancing the fixing power and thus reducing fading. Alternatively, a more reactive or direct dye can be used to improve the color fastness to washing and reduce fading. What’s more, you can click here and learn more.

Q: What is the difference between wash fastness testing with soap and wash fastness testing with water?

A: Wash fastness testing with soap focuses on simulating the fading of textiles during routine low-temperature washing, using soap or detergent. In contrast, wash fastness testing with water simulates high-temperature washing, suitable for more demanding environments, such as industrial laundering. The primary difference between the two lies in the washing temperature and conditions; the former is suitable for home use scenarios, while the latter is more appropriate for high-demand cleaning applications.

Q: How many types of Colour Fastness Tester are there?

A: There are several types of Colour Fastness Testers, including washing fastness testers, light fastness testers, rubbing fastness testers, friction fastness testers, perspiration fastness testers, water fastness testers, bleach fastness testers, and chemical fastness testers, each designed to evaluate specific aspects of color retention under various conditions.

Q: Why SmartDispen Detergent Dispenser is important for color Fastness to Washing testing?

A: The SmartDispen Detergent Dispenser is an essential device for color fastness to washing testing, designed specifically for this purpose.

SmartDispen enhances sample preparation efficiency by six times, making the testing process faster: with three independent stations, it can prepare different soap solutions, so for 24 test cups, traditional manual preparation takes over 20 minutes, while SmartDispen only requires 3 minutes.

The testing is also more reliable, as it automatically weighs the samples, dispenses the soap solution according to the bath ratio, stirs automatically, adds water, and outputs the set number of steel balls, effectively preparing all the necessary samples for wash fastness testing in one go, thus reducing human error in the process.

Q: What types of fabrics can be tested for this Washing Fastness Tester?

A: The WashTrue Washing Fastness Tester is suitable for testing a variety of fabric types, including natural fibers like cotton, linen, silk, and wool; synthetic fibers such as polyester, nylon, acrylic, and spandex; as well as blended, knitted, and woven fabrics, providing reliable results for quality control in textile manufacturing.

Q: What scale is color fastness to washing rated on?

A: Color fastness to washing is rated on the gray scale, which is a standardized method used to evaluate the degree of color change and staining after washing tests. The gray scale typically ranges from 1 to 5, where 1 indicates very poor fastness (significant color change or staining) and 5 signifies excellent fastness (no noticeable change or staining).

Q: What are the testing conditions for fabric’s color fastness to wash?

A: Washing colorfastness is tested under controlled conditions that include varying washing temperatures (typically from 30°C to 60°C or higher), standardized washing times, specific detergent types and concentrations, mechanical agitation levels, clean water quality, consistent sample preparation, rinsing conditions, and standardized assessment criteria for evaluating color change and staining.

Q: What factors can affect wash fastness test results?

A: Factors such as the type of dye used, fabric composition, washing temperature, detergent type, and washing machine settings can all influence the wash fastness results.

Q: What are the reasons for failing the colour fastness to washing?

A: Inappropriate Dye Selection

Using low-quality dyes or dyes that do not have sufficient affinity for the fabric can lead to fading or loss of color during washing.

Dyeing Process Issues

Poor control during the dyeing process, such as temperature, time, and pH levels, may result in uneven dyeing or weak dye adhesion.

Fabric Material

Certain materials (such as some synthetic fibers) may have a weak adsorption capacity for dyes, leading to dye loss during washing.

Washing Conditions

Improper washing conditions, including temperature, duration, detergent type, and concentration, can affect color fastness performance. High temperatures or strong alkaline detergents may accelerate dye fading.

Mechanical Agitation

Excessive mechanical agitation during washing can cause significant friction on the fabric surface, accelerating color loss.

Post-Treatment Processes

Post-treatment processes (such as softeners or wrinkle-resistant treatments) may affect the dye's durability. Improper post-treatment can lead to dye loss or fading.

Storage Conditions

Exposure to strong light, high temperatures, or humid environments during storage can decrease color fastness.

Non-Compliance with Testing Standards

If the wash fastness test is not conducted according to relevant standards, it may lead to inaccurate results and misjudgment of color fastness levels.

Q: How long does it take for soap to dissolve at different temperatures?

A: The dissolution times for soap at various temperatures are as follows:

40°C: 87-93 minutes

50°C: 23-24 minutes

60°C: 16-17 minutes

90°C: 6-7 minutes

Q: What issue may occur after wash fastness testing?

A: After wash fastness testing, some samples may exhibit residual white deposits, which can affect the assessment of color change levels. These deposits may result from undissolved soap or other substances, leading to inaccuracies in evaluating the fabric's color fastness performance.

Q: What solutions can improve color fastness?

A: To address substandard color transfer, consider the following solutions:

Improve fabric dyeing performance, such as dye penetration and fixation, and enhance soap washing and reduction cleaning to effectively remove floating color.

Use fixing agents to enhance the fabric's wash and water color fastness.

Employ appropriate additives to prevent sweat from damaging the dye structure.

Related products

-

Color Matching Cabinet TU300A/B/C/D

Rated 4.78 out of 5 -

Rotary Crockmeter TF412

Rated 4.50 out of 5

Edision –

It is very good to be able to test both AATCC standards and ISO standards.

James Harden –

This instrument is recommended for testing the colour fastness of fabrics to washing, it works very well.

Richard –

Great to have one machine for meeting two standards testing requirements.

Sherrif –

For two major standards testing, ISO and AATCC, this launderometer is enough

James Charles –

I bought this Launderometer to help check the color fastness for a couple of upcoming projects. It more than paid for itself the day I got it.

Cliff Michael –

Although it is a little bit expensive,it is worthwhile.Will come again.

Sabina Bridges –

Perfect washing fastness tester,thanks manufacturer.

Zachary Sherwood –

The Launderometer testing well

Moses Duncan –

I am so satisfied with this washing fastness tester for its reasonable price and good performance. Recommend!

Rock –

everything is ok

Ellen –

На вид очень качественный.