Now, mask factories in European and American countries are facing some pressure: on the one…

What does the Best Seller Mask Making Machine Look Like?

With the prolongation of the epidemic, in the future, the production of masks will become more routine, in the face of the various mask making machines on the market, which one is the most practical? Today I’m going to take a look at 4 things that are required for the best seller mask making machine.

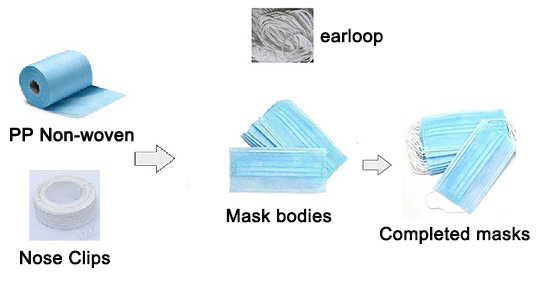

Generally speaking, there are two main steps in the mask production: mask slicing and earloops welding. The first step, make the mask bodies with the PP Non-woven fabric and the nose clips to meet the standard specifications, and then weld the earloops to make a completed mask. During the whole process of mask production, the most important thing is that the mask bodies made by the mask slicer can maintain a stable shape and size, so as to ensure the stability of the earloops welding.

The four conditions of the best seller mask making machine

1 They say a fully automatic mask machine is good, so what should you look out for before buying a fully automatic mask making machine?

The mask slicer of semi-automatic and fully automatic are the same machine, the difference between them is the earloops welding step, semi-automatic requires manual welding, debugging is very simple, while fully automatic is automatic welding after slicing, but machine debugging is difficult. There is a process of debugging and test run before the mask machine leaves the factory. Obviously, the more problems found and solved in this process, the smaller the probability of problems with the mask machine after leaving the factory.

Therefore, fully automatic is much better than semi-automatic, provided that the mask making machine has adjusted by the manufacturer. In addition to stability and high speed, more importantly, with the same capacity, a fully automatic mask making machine saves at least 10 labors compared to a semi-automatic mask making machine.

2 How to design a fully automatic mask making machine to ensure optimal production process?

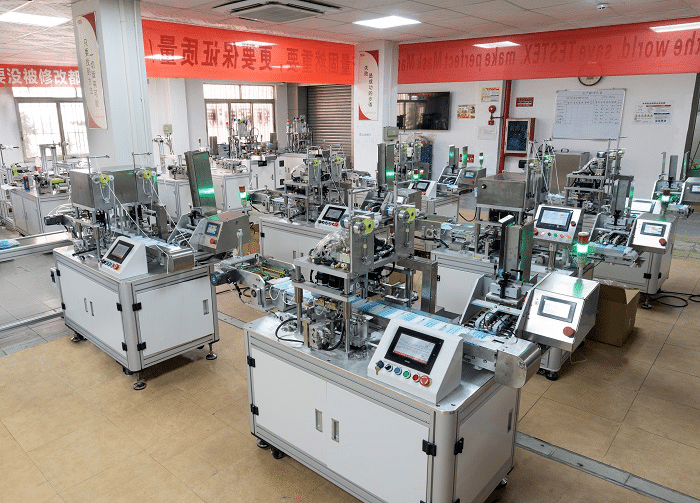

The automatic mask machine on the market is generally divided into automatic one-tractor mask machine and one-tractor two mask machine. According to the experience in the production of mask making machines and market research, a one-tractor mask machine is more practical and more efficient than a one-tractor two machine.

Why is the fully automatic one-tractor two mask machine unstable? Because in the design of one-tractor two masks machine, it is difficult to match the film making machine with two welding machines and the middle parting system plus four conveyor belts. In addition, because there are too many machines to fit together, and there are four or five parts, if any part fails, the whole line will have to stop, so the machine can only be opened very slowly, generally no more than 60 pieces/min.

One-tractor mask machine, a mask slicer machine and a welding machine, only a conveyor belt, save the piece system, four conveyor belts, and a welding machine, reducing the components to fit together, the probability of a total line stoppage due to a partial failure is reduced. In addition, because there are fewer components to fit together, the one-tractor full automatic mask making machine can produce at high speed, unlike the one-tractor two, which can only run at a low speed in order for the components to fit together.

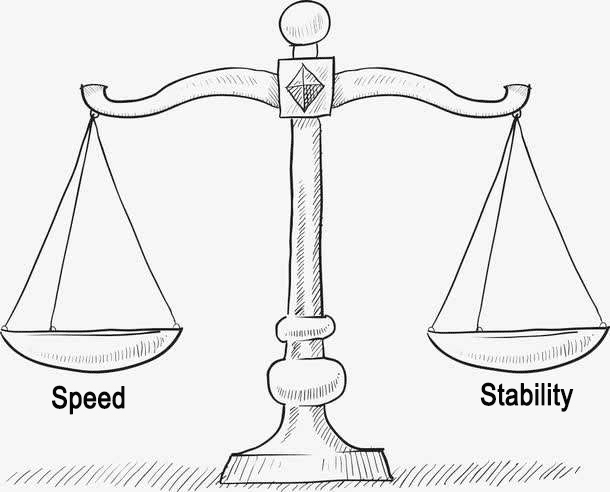

3 How to balance the speed and stability of the mask making machine?

Theoretically, when the speed is within a certain range, the machine will run consistently, but once the speed exceeds a certain threshold, the machine is prone to run out of order and cause all sorts of problems. (The speed of the mouthpiece machine refers to **pcs/min)

If the speed is too low, the output cannot keep up, and if the speed is too high, the machine is not stable and the quality is not guaranteed. Therefore, we need to find the speed range that can guarantee the output and the quality, and after the experience and the feedback from the customers, we generally find that the speed and stability of the machine is perfect when the speed is in the range of 80pcs/min~100pcs/min.

4 When the customer receives the machine, can they set it up and start production quickly and how long will the machine last?

After receiving the machine, whether the operator can quickly start to skillfully operate the machine, and how quickly the machine can produce a stable batch, etc. The importance of these is self-evident, which will not only affect the schedule of production, seriously, it will reduce the company’s tolerance for error and greatly increase the risk of loss. Therefore, before buying a machine you should find out how long the manufacturer has been debugging it, what problems have been solved, how often the machine will run out of order under normal circumstances, etc.

For now, this epidemic is a once-in-a-century crisis in human history, and no one knows when it will end and in what way it will end. Therefore, it is also important to know how long the mask machine will last, and the core components (ultrasonic and servo motors) of the mask machine must be of high quality in order to ensure the continuity of mask production.

In any case, until a vaccine is actually developed, when faced with the dilemma of economic recovery and epidemic crisis, the only thing we can do is to wear the mask and resume production in an orderly manner.

This Post Has 0 Comments