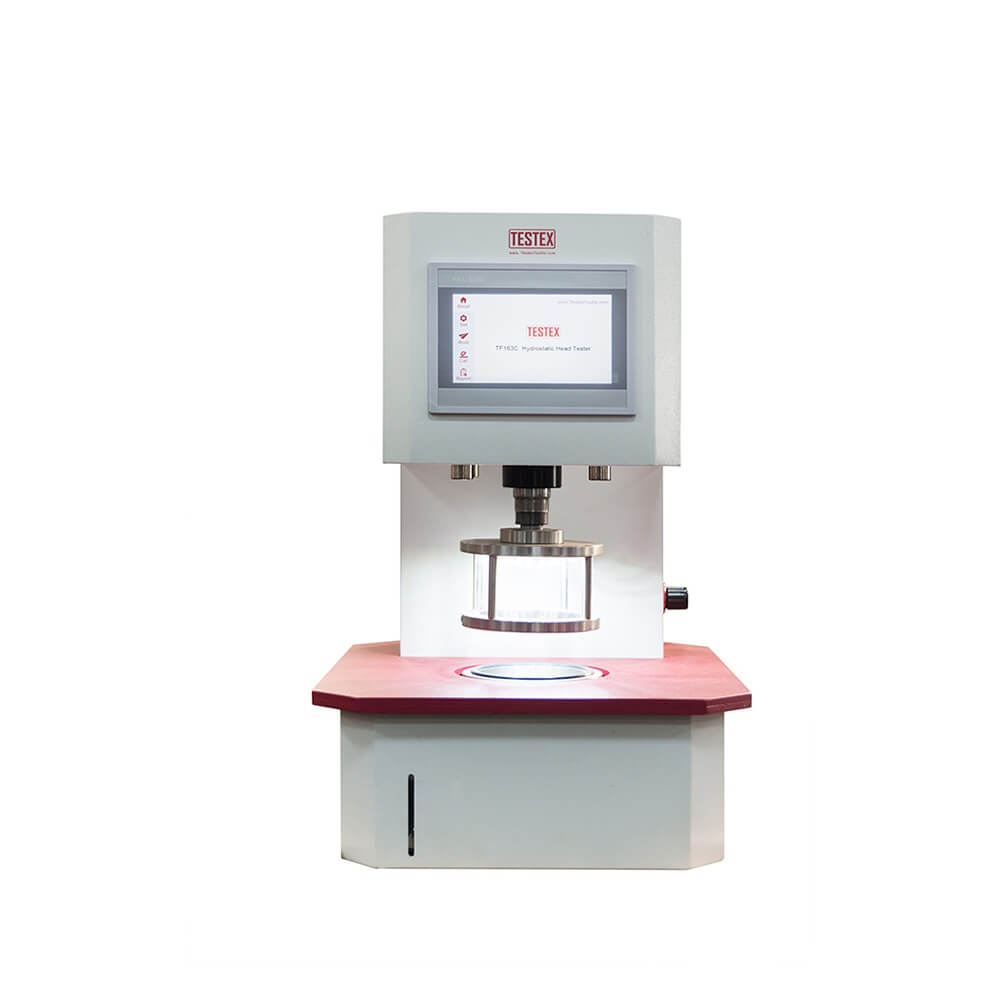

Hydrostatic Head Tester TF163C

A Hydrostatic Head Tester or Hydrostatic Pressure Testing Machine, is one kind of Water Penetration Tester. It is used to measure the waterproof properties of fabric through the water pressure. It is one of the hydro-testing machines. Hydrostatic Head Tester TF163C complies with Hydrostatic Head Testing standards like AATCC127, ATSC127-2008, EN 20811, ISO 811, etc. Contact us now for the Hydrostatic Head Tester promotional price.

Description

Features of Hydrostatic Head Tester TF163C

1. High Configuration, Accurate Testing

The machine is controlled by a precise industry-grade processor

and equipped with a 1-bit high-precision AD chip to collect real-time pressure value.

2. The original hydraulic balancing system can make the pressure rise steadily.

Meanwhile, the booster system adopts dynamic feedback adjustment to prevent overload.

3. Pneumatic fixture for fixing samples, fast, firm, and convenient

4. 3 testing modes to meet more customer needs, including boost mode,

constant pressure mode, and constant pressure timing mode.

5. Equipped with LED lights, easy to observe the testing process, at the same time,

the test results are displayed in real-time on the large color touch screen,

which can form a report and print out the results directly.

Application of Hydrostatic Head Tester TF163C

Hydrostatic Head Tester TF163C, also named hydrostatic pressure testing machine TF163C can determine the resistance of a fabric to the penetration of water under hydrostatic pressure. It is applicable to all types of fabrics, including canvas, coated fabrics, cover fabrics, rainwear fabrics, and geotextile materials, as well as films, those treated with a water-resistant or water-repellent finish, etc.

You can also learn more about hydrostatic head testing methods.

Specifications of Hydrostatic Head Tester TF163C

- Test pressure: 0~3000mbar

- Measuring accuracy: ± 0.5 % of displayed £¦#118alue ± 1 mbar

- Readability: 0.1 bar

- Pressure gradient: 1~500bar/min

- Test area: 100 cm2 (10 cm2, 19.63 cm2, 26 cm2 and 28 cm2 optional)

- Maximum sample thickness: 5mm

- Required compressed air supply: 6~8 bar (clean and dry)

Weight

| 85 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: | 360 mm | Widh: | 460 mm | Height: | 450 mm |

Standards

| GB/T 4744 | AATCC 127 | EN 20811 | BS 2823 |

| BS 3424-26 29A | BS 3424-26 29C | BS 3321 | ISO 811 |

| ISO 1420A | DIN 53886 | INDA IST 80.4 | JIS L 1,092 A |

| JIS L1092 B-b | NF G07-057 | ERT 120-1 | ERT 160-0 |

| EDANA 120.2-02 | ISO 16603 | ASTM F1670 | YYT 0700 |

| ASTM F903 |

Know More about Hydrostatic Head Tester

Definition of hydrostatic pressure

Hydrostatic pressure refers to the resistance encountered when water passes through the fabric. Water pressure rises continuously on the fabric. It stops when water beads up on the back of the fabric at standard pressure. At this point, the measured water pressure value is the hydrostatic pressure. The more pressure the fabric can withstand, the better its waterproofness.

Hydrostatic pressure units

The hydrostatic pressure can be expressed in N/㎡, Kpa, and water column height m. And the conversion unit is 1m water column height equals 9.82Kpa.

Precaution and Maintenance of Hydrostatic Head Tester TF163C

Before the first operation, the operator must read the Manual. They must do this carefully and get special training.

Sweep the top chuck lightly. Do this before placing the specimen. It prevents affecting the test results.

The cylinder’s default value is 0.5MPa. You can adjust it to fit the specimen. The maximum error range should not exceed plus or minus 0.2MPa.

4 The inlet pressure should be less than 0.8MPa but the maximum pressure should not exceed 1MPa.

5 Turn off the power and then remove the plug from the power outlet after each test.

6 The emergency stops and restarts the instrument in the event of a malfunction.

7 To ensure the normal operation of the machine, the user must regularly check the water level of the test tank. Meanwhile, drain the water out if the machine will keep idle for a long time. So, turn on the drain switch. Turn it horizontally toward the outlet pipe. And, avoid wetting the electrical equipment. After completing the drainage, close the drainage switch (vertically to the outlet pipe). Check that the switch and the pipe mouth do not fall off.

8 Keep the touch screen away from sharp, hard objects and there is no strong electromagnetic interference in the surroundings.

Welcome to TESTEX – a professional textile testing instrument supplier – Hydrostatic Head Tester TF163C is on sale, contact us to get a detailed price quote. You can also learn more about our sister company, which provides more advanced textile testing machines.

14 reviews for Hydrostatic Head Tester TF163C

You must be logged in to post a review.

Hydrostatic head Test Method

What is a hydrostatic head tester:

The definition of the hydrostatic head is the pressure of homogeneous fluid acting on an object, which can be explained that each part of an object is forced uniformly. The object will shrink its volume when the hydrostatic pressure is enhanced, but the shape will not be changed.

Hydrostatic head test method:

Place a test sample on the clamping head and set the parameters of the test of the Android software on the Samsung pad; Then the system automatically starts by pressing down the upper clamping arm; During the test, the system automatically adjusts the machine and shifts nozzles if required; after a few seconds the test results are then displayed and excel report is generated; the reports can be output to a USB / SD card, or send to any network by WIFI connected.

Hydrostatic head test procedure:

1. Turn on the power.

2. Turn on the air pump and adjust the air pressure governor to ensure that air pressure is in a reasonable range.

3. Pour water into the water tank until it reaches the highest water level.

4. Setting and saving the parameter on the setting page according to the standard, and going to the test page.

5. Place the sample on the clamp to fix it, and then zero or clear the machine. (Note: The machine should be zeroed or cleared under natural water pressure, otherwise the test results will be inaccurate.)

6. Start the test and observe the sample. When the third water droplet has appeared on the surface of the sample, we should stop the test and record the data.

7. After that, we need to release the sample and change it to another one for the next test.

8. Draining the water after all the test is finished, and turning the power off.

Factors influencing fabrics' hydrostatic pressure resistance

1. The tightness of the fabric. The increase in distance between the yarns will directly affect the level of water pressure resistance. The tighter the general fabric structure, the better its resistance to water penetration performance.

2. The size of the coating film aperture, the larger the aperture of the film, the worse the hydrostatic pressure resistance of the coating film aperture.

3. The size of the contact angle θ. When θ>90°, the fabric has water-repellent properties, at this time with the increase θ fabric water pressure resistance value will also increase.

4. The thickness of the coating. The coating layer is too thin, and the coating agent on the surface is not easy to form a continuous film. The water pressure resistance of the coated fabric is reduced; the coating is thick, and the water pressure resistance of the fabric is increased.

5. the thickness of the fabric. The thicker the fabric, the greater the wet resistance, and the greater the water pressure resistance value.

6. The thickness of the yarn. For moisture-absorbent fibers woven into compact fabrics, due to the existence of the capillary effect, reducing the yarn radius, can improve the water-resistance of the fabric.

7. The performance of the warp and weft yarns. By the role of water pressure, good elasticity of the warp and weft yarn is easy to elongate, which leads to the formation of adjacent warp and weft yarn gap, water beads easier to seep through, making the fabric water pressure resistance value reduced.

8. Coating quality. The entire fabric surface is required to be uniform and has a certain degree of fastness. The better the quality of the coating, the better the resistance to water penetration.

We can also provide a pdf of the standard water resistance (hydrostatic pressure) test if you need it, please contact us via email: [email protected].

[contact-form-7 id="16355" title="Inquiry"]

A: Hydrostatic pressure refers to the water permeability of fabrics under certain water pressure. It is suitable for all kinds of fabrics, including those treated with waterproofing. The hydrostatic pressure method is used to measure the waterproofing of the fabric. There are static pressure methods and dynamic pressure methods. Static pressure is used for water-conducting fabrics, and dynamic pressure is used for coated or compact fabrics.

Q: Is this machine to measure the water resistance / proofness of PU/PVC samples (Water column test)?

A: Yes, it is.

Bill Dickey –

It is exactly what we want. Thanks manufacturer.

Uriah Leigh –

Excellence! Works rapidly and accurately.

Rebecca Zimmerman –

Great Hydrostatic Head Tester at a great price.

Lylyzzz –

Gran máquina

Una Hood –

Hydrostatic Head Tester received.Works as expected.

Towfik –

very useful side

Ann Vaughan –

I can complain nothing.Whether product or service are perfect!

Lucy Gold –

Good product !Good textile equipment supplier! All of well!!

Wendy Cronin –

With the hydrostatic head tester, I save more time. Thanks manufacturers!

Vincent Tuttle –

The Hydrostatic Head Tester suppiler is kind to help me solve some problems. Will return to buy.

Zara Wilde –

The hydrohead test machine is great. Although there is a little problem, the seller solve quickly.

testextextile –

Glad you satisfy our service. Thanks a lot.

Steward Hoover –

Came very fast, the very attentive seller, the product is great, met my expectations, I recommend, the product from this seller,

Frederica –

Goods of high quality, fast shipping and delivery, I recommend the seller and his shop.

Elsa B. –

Good product i think that is very accurate but i dont have any reference but is ok. good package. not damaged.

testextextile –

We are very glad to bring better purchase experience to our customer, also really very appreciate for your positive feedback as it’s very important for us. Hope we could do further business with you later on. Thanks for your purchase again!